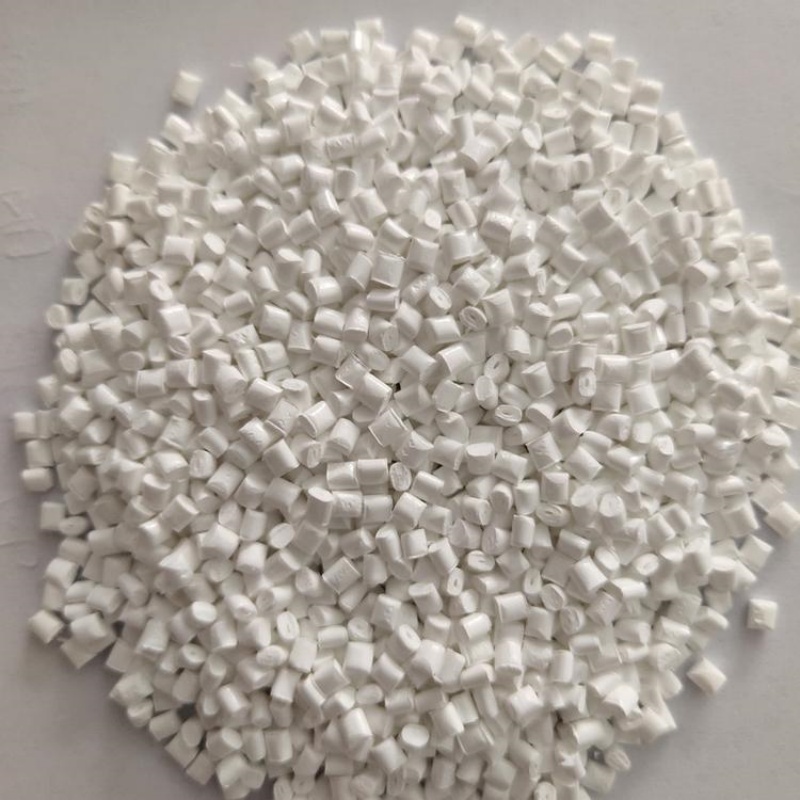

PA6 Unfilled Flame Retardant (Halogen-Free Polyamide 6) offers superior flame resistance, excellent mechanical properties, and enhanced thermal stability. Designed for electrical enclosures, automotive components, and industrial applications, it ensures fire safety, durability, and long-term reliability.

Product Overview

PA6 Unfilled Flame Retardant is a halogen-free, flame-retardant polyamide 6 (PA6) material. This product offers excellent flame resistance without containing red phosphorus or halogens, meeting environmental protection standards. With its superior mechanical strength, outstanding electrical properties, and good colorability, it is widely used in the electrical and electronics industries.

Key Features

- Halogen-Free Flame Retardancy: Free of halogens and red phosphorus, this material complies with environmental standards, making it suitable for green and eco-friendly products.

- Superior Mechanical Strength: Offers excellent tensile strength, impact resistance, and wear resistance, making it ideal for high-load environments.

- Excellent Electrical Properties: Features outstanding electrical insulation, ensuring stable electrical isolation in electrical devices.

- Easy to Color: This material can be easily colored to meet a wide range of design requirements.

- Environmentally Compliant: Fully meets environmental protection standards, ideal for halogen-free product manufacturing.

Applications

- Electrical Equipment Buttons: Used for buttons in various electrical devices, ensuring safety and long-term stability.

- Connectors: Used as a material for connectors in electronic and electrical devices, offering good electrical performance and flame retardant protection.

- Electrical Components: Ideal for manufacturing a range of electrical components, ensuring safety and stability under high temperatures and heavy load conditions.

| Test Properties | Unit | Test Method | Test Condition | Typical Value |

| Physical Properties | ||||

| Density | g/cm³ | ISO 1183 | 1.18 | |

| Filler Content | % | ISO 1172 | - | - |

| Mold Shrinkage | % | ISO 294 | Parallel: 1.2%, Vertical: 1.8% | |

| Mechanical Properties | ||||

| Tensile Strength | MPa | ISO 527 | Type I sample, 50mm/min | 75 |

| Elongation at Break | % | ISO 527 | Type I sample, 50mm/min, Gauge length 50mm | 2 |

| Flexural Strength | MPa | ISO 178 | 23℃, 10mm/min | 100 |

| Flexural Modulus | MPa | ISO 178 | 23℃, 10mm/min | 3200 |

| Izod Impact Strength (Notched) | KJ/m² | ISO 180 | 23℃ | 3 |

| Charpy Impact Strength (Unnotched) | KJ/m² | ISO 179 | 23℃ | 50 |

| Thermal Properties | ||||

| Melting Point | ℃ | ISO 11357-1 | 260 | |

| Heat Deflection Temperature (HDT) | ℃ | ISO 75 | 0.45MPa: 200℃, 1.8MPa: 75℃ | |

| Flammability | ||||

| UL Flammability Class | UL-94 | V0 | ||

| Glow Wire Ignition Temperature (GWIT) | ℃ | IEC 60695-2-13 | 775 | |

| Electrical Properties | ||||

| Surface Resistivity | Ω | IEC60093 | 100000000000000 | |

| Volume Resistivity | Ω·cm | IEC60093 | 1000000000000000 |

new material

new material