Electrodeposited nickel diamond products (N56) are advanced composite materials engineered for extreme hardness, wear resistance, and enhanced thermal stability. Utilizing precision electroplating techniques, these products feature a high-density distribution of synthetic diamond particles within a durable nickel matrix, ensuring superior cutting efficiency and prolonged tool lifespan. N56-grade materials are widely applied in precision grinding, aerospace tooling, semiconductor manufacturing, and industrial machining processes that demand optimal durability under intense operational conditions.

Product Overview

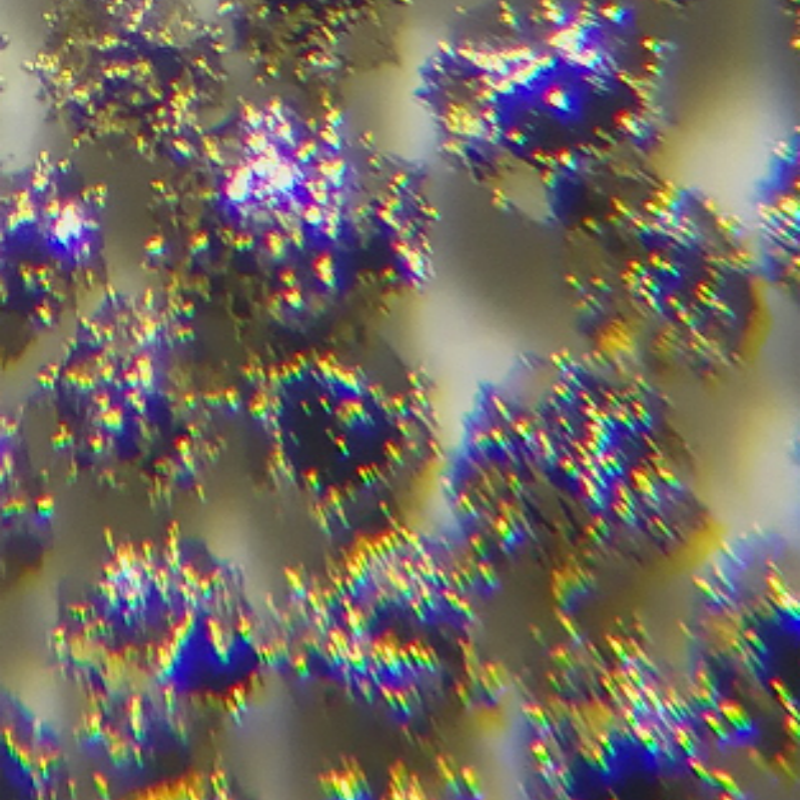

Electrodeposited nickel diamond products (N56) are created by an electrodeposition process that forms a uniform and complete nickel layer on the surface of diamond particles. The nickel coating is spiky, providing a strong surface bonding force that significantly enhances the bond strength between the diamond particles and the tool matrix. This nickel coating helps improve the overall performance of diamond tools, especially under high-load working conditions, offering longer tool life and more stable performance.

Features

- Uniform and Complete Electrodeposited Nickel Layer: The nickel layer is uniform and tightly bonded to the diamond particles, providing enhanced mechanical stability.

- Spiky Surface Structure: The spiky surface structure effectively improves the bond strength between diamond particles and the tool matrix.

- Improved Holding Strength: Significantly improves the stability of diamond particles in the tool matrix, enhancing the tool’s durability.

- Adaptable to High Load Working Conditions: By improving particle bonding strength, the product is suitable for high-load, demanding machining environments.

Applications

- Resin Bonded Tools: Suitable for diamond tools with resin binders, enhancing tool performance and efficiency.

- Ceramic Bonded Tools: Especially suitable for diamond tools with ceramic binders, improving wear resistance and machining stability.

- High Load Working Environments: Suitable for cutting and grinding tools used in high-load conditions, ensuring efficient and durable performance.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform