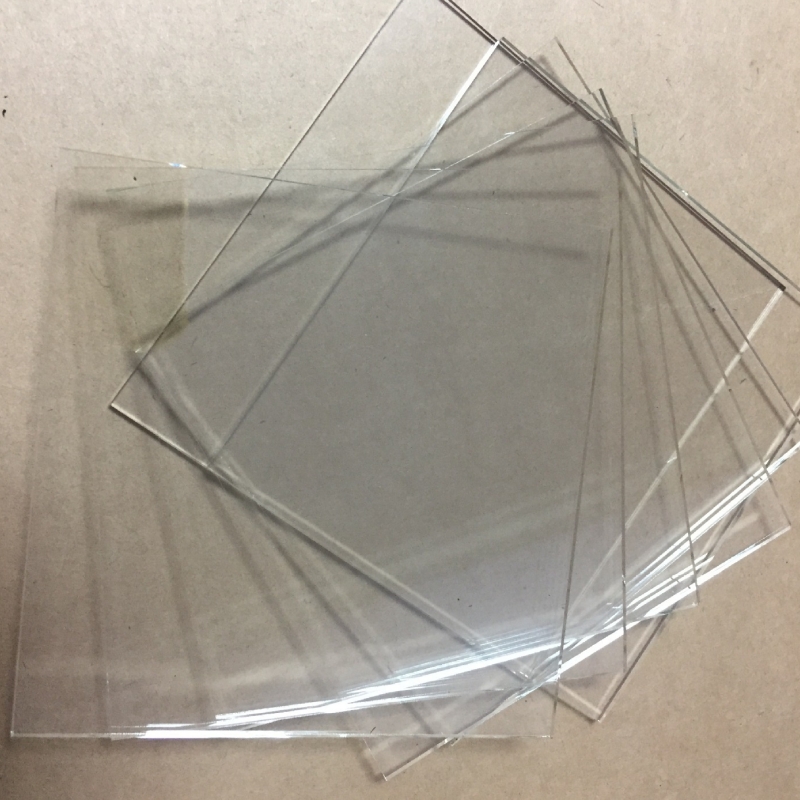

Borosilicate glass is a high-performance material known for its superior thermal resistance, chemical durability, and optical clarity. Engineered with silica and boron oxide, this glass exhibits low thermal expansion, making it highly resistant to temperature changes and ideal for applications requiring high precision. Borosilicate glass is widely used in laboratory equipment, industrial optics, cookware, aerospace components, and specialized scientific applications. Its strength and reliability make it a preferred choice for demanding environments.

Product Overview

Borosilicate 3.3 heat-resistant shock-resistant float glass is a type of flat glass made primarily from sodium oxide, boron oxide, and silica through the float process. It is characterized by a low coefficient of thermal expansion, excellent thermal stability, and chemical resistance. Borosilicate glass is widely used in applications that require high strength, heat resistance, and resistance to chemical corrosion. Due to its outstanding thermal shock resistance, good light transmittance, and excellent electrical properties, it is widely applied in various demanding industrial and scientific fields.

Key Features

- Low Coefficient of Thermal Expansion: With a small thermal expansion coefficient, it can withstand rapid temperature changes, reducing the risk of cracking due to thermal expansion.

- Good Thermal Stability: Can operate stably in high-temperature environments without easily deforming.

- Excellent Chemical Stability: Strong resistance to chemical corrosion, making it highly resistant to acids, alkalis, salts, and other chemicals.

- High Light Transmittance: Offers excellent light transmission, suitable for applications requiring high transparency.

- Thermal Shock Resistance: Capable of withstanding significant temperature fluctuations, making it ideal for high-temperature and thermal shock environments.

- High Hardness: Surface hardness is high, providing strong wear resistance.

Applications

- Laboratories and Chemical Industry: Widely used in laboratory equipment, reactors, flasks, test tubes, etc., as it can withstand chemical corrosion and high-temperature operations.

- Kitchenware and Home Appliances: Applied in kitchenware such as heat-resistant cookware and oven doors, capable of withstanding high-temperature baking and heat-resistant cleaning.

- Lighting Industry: Used in high-temperature lamps, UV light tubes, and other equipment as lamp tube materials.

- Electronics Industry: Used as the casing for electronic components, particularly in high-temperature and high-pressure environments.

- Medical Equipment: Used in medical devices, instrument windows, and other applications that require excellent thermal stability and high transparency.

- Aerospace: Used in spacecraft, satellite windows, housings, and other components exposed to high temperatures and pressures.

- Construction Industry: Used in windows, curtain walls, special thermal insulation glass, and other building materials, providing excellent thermal stability and light transmission.

| Mechanical Properties | Densityρ | 2.23±0.02g/cm3 |

| Mohs Hardness | Greater than 7 | |

| Thermodynamic Properties | Coefficient of Thermal Expansion | (0-300℃) (3.3±0.1)×10⁻⁶ K⁻¹ |

| Softening Point | 820±10℃ | |

| Strain Point | 516±10℃ | |

| Specific Heat Capacity | (20-100℃) 0.82 KJ×(kg×K)⁻¹ | |

| Thermal Conductivity | 1.2 W×(m×K)⁻¹ | |

| Thermal Shock Resistance | 180 K | |

| Maximum Temperature Difference in the Same Plate | 100 K | |

| Maximum Operating Temperature | Short-term(<10h) 500℃, long-term(>10h) 450℃ | |

| Chemical Properties | Water Resistance | ISO719/DIN12111 HGB1, ISO720 HGA1 |

| Acid Resistance | ISO1776/DIN12116 1 | |

| Alkali Resistance | ISO695/DIN52322 A2 | |

| Optical Properties | Refractive Index | Nd:1.47384 |

| Transmittance | >91% | |

| Electrical Properties | Resistivity lgρ | 250℃ 8.0 Ω×cm |

| Dielectric Loss | tanσ(1 MHz, 20℃) 38×10⁻⁴ | |

| Dielectric Constant ε | 4.7 | |

| Dimensions and Thickness | Maximum Size | Standard 750mm×1200mm, custom length unlimited |

| Thickness | Float glass process: 1.5——25mm, other processes: 0.5——150mm |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform