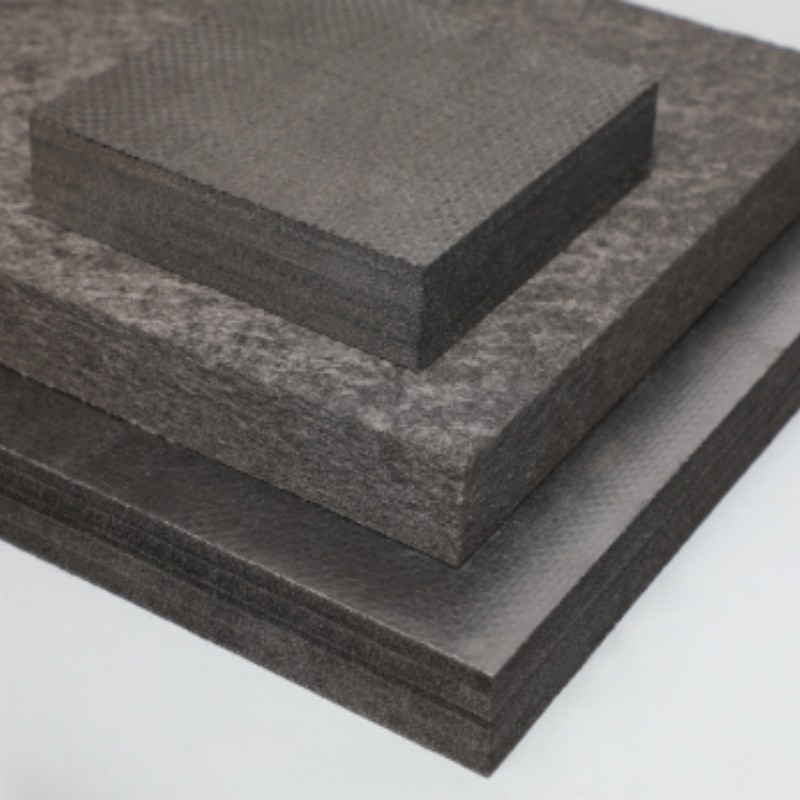

Carbon fiber cured felt is a high-performance thermal insulation and reinforcement material designed for applications requiring superior heat resistance, optimized structural integrity, and enhanced mechanical durability. Manufactured through controlled carbonization and curing processes, this felt provides excellent stability, lightweight properties, and reliable compatibility with advanced composite systems. It is widely used in aerospace, industrial thermal insulation, high-temperature furnaces, energy storage applications, and structural reinforcement solutions, ensuring long-lasting efficiency in demanding environments.

Product Overview

Carbon fiber cured felt is made by layering carbon fiber soft felt or forming short fibers into a solid shape, followed by high-temperature graphitization treatment. As a rigid material, it has excellent self-supporting properties, is easy to install and remove, and has strong fiber bonding. Carbon fiber cured felt offers outstanding resistance to gas flow erosion, thermal insulation, low heat capacity, and uniform density, making it particularly suitable for high and ultra-high-temperature environments.

Key Features

- Customizable: Can be tailored into different shapes to meet specific installation and application requirements.

- Excellent Thermal Insulation: Provides effective thermal insulation, making it ideal for high-temperature applications.

- Low Heat Capacity: Has a low heat capacity in high-temperature environments, reducing energy wastage.

- Gas Flow Erosion Resistance: Adaptable to harsh environments, with minimal risk of degradation.

- Strong Self-Supporting: Stable structure allows for independent use, reducing dependency on other support materials.

- Uniform Density: Ensures consistent material properties and stable thermal insulation performance.

Applications

- High-Temperature and Ultra-High-Temperature Industrial Furnaces: Such as metal heat treatment furnaces, sintering furnaces, single-crystal silicon furnaces, crystal growth furnaces, and fiber optic production furnaces. It serves as high-quality thermal insulation material.

- Temperature Control & Furnace Protection: Helps control internal furnace temperature, protects the furnace body, and optimizes energy use.

- Special Industrial Fields: Suitable for environments with high demands on temperature and heat capacity, ensuring safety and efficiency.

- Customized Thermal Field Management Solutions: Offers tailored thermal field management solutions to enhance production efficiency.

| Technical Indicators and Parameters | |||||

| Indicator Name | Index parameter | Note | |||

| PAN-based | Viscose-based | Asphalt-based | |||

| Carbon Content (wt%) | ≥99.8 | ≥99.8 | ≥99.9 | ||

| Ash Content | ≤300 | ≤300 | ≤200 | ||

| Thermal Conductivity | 1000℃ | <0.3 | <0.2 | <0.2 | Vacuum Environment |

| W/(m·K) | 1500℃ | <0.5 | <0.3 | <0.3 | |

| Bulk Density (g/cm³) | 0.15~0.25 | 0.13~0.20 | 0.18~0.20 | Customized | |

| Treatment Temperature (℃) | 2000 | 2000 | 2000 | ||

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform