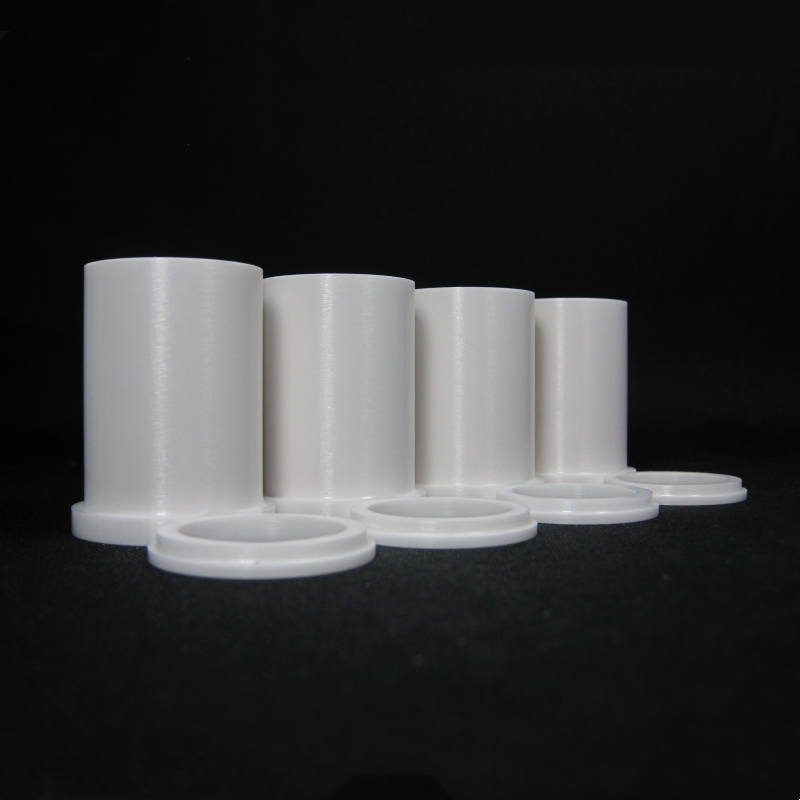

The ZTA composite zirconia ceramic sleeve offers exceptional wear resistance, optimized mechanical strength, and superior thermal stability. Designed for industrial applications, it ensures extended durability, precision-engineered performance, and reliable structural integrity.

Product Overview:

The ZTA composite zirconia ceramic sleeve is made from a combination of zirconia (ZrO2) and alumina (Al2O3), combining the high-temperature resistance and hardness of zirconia with the wear resistance of alumina. This composite material sleeve is widely used in high-temperature, high-pressure, and highly abrasive mechanical equipment, providing exceptional durability and stability in harsh environments.

Product Features:

- Excellent Wear Resistance:Effectively increases the service life of equipment.

- High Temperature Resistance:Maintains stability and strength even at extremely high temperatures.

- Chemical Corrosion Resistance:Resists corrosion from a wide range of chemicals.

- High Toughness and Bending Strength:Ensures reliability under heavy load conditions.

- Excellent Thermal Insulation:Reduces heat transfer in equipment.

- Anti-Magnetic Properties:Suitable for environments where magnetic interference must be avoided.

- Thermal Expansion Coefficient Close to Steel:Improves compatibility with other materials.

Applications:

- High-Temperature Mechanical Equipment:Widely used in engine sleeves, pumps, compressors, and other machinery.

- Chemical and Metallurgical Industries:Applied in chemical reactors and high-temperature smelting equipment.

- Energy and Aerospace:Used in high-temperature, wear-resistant components such as combustion chambers and turbines.

- Heavy Machinery Manufacturing:Suitable for mechanical parts that undergo long working hours and are prone to wear.

- Smelting and Refining Equipment:Used in high-temperature, high-wear parts like furnaces, furnace tubes, and furnace walls.

new material

new material