Zirconium oxide ceramic sheets (ZrO₂ ceramic sheets) offer superior mechanical strength, optimized thermal stability, and excellent chemical resistance. Designed for high-performance industrial applications, they ensure precise structural integrity, extended durability, and reliable functionality.

Product Overview:

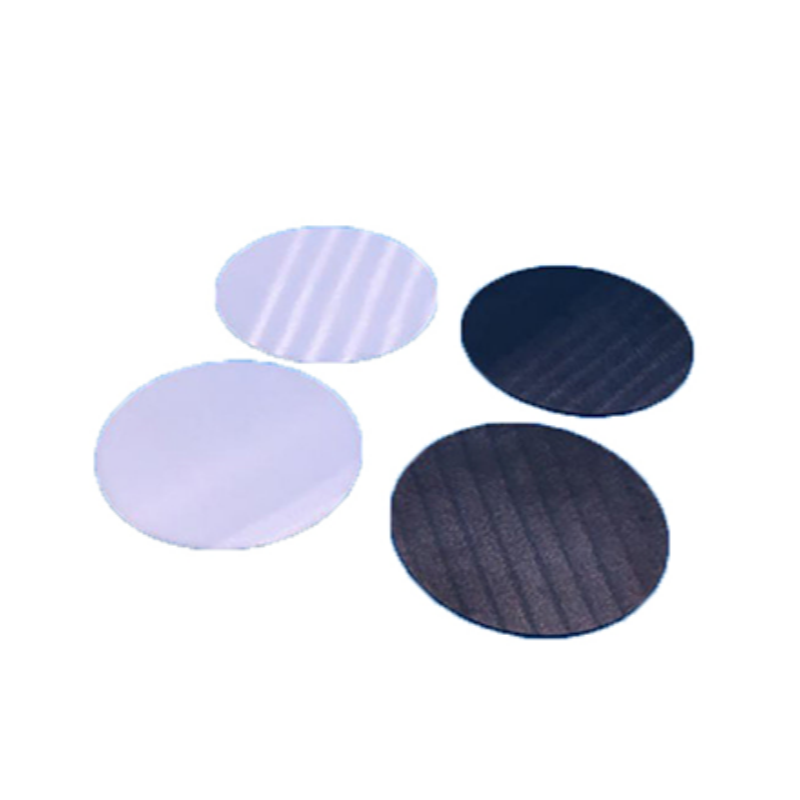

Zirconium oxide (ZrO₂) ceramic sheets are a high-performance material known for their excellent high-temperature resistance, wear resistance, and corrosion resistance. These sheets are widely used in applications requiring high strength and durability. Pure zirconium oxide is typically white, but may appear yellow or gray when containing impurities. Zirconium oxide exists in three crystal forms, and the production process requires powders with good dispersion and fine particle size to ensure consistency and stability in various industrial applications.

Product Features:

- High Temperature Resistance:Features a very high melting point and excellent heat resistance.

- High Hardness:Provides good wear resistance and mechanical strength.

- Excellent Chemical Stability:Resists corrosion from a wide range of chemical substances.

- Good Electrical Insulation:Acts as an insulator at room temperature.

- Good Particle Size Distribution:Suitable for precision manufacturing and high-standard industrial applications.

Applications:

- High-Temperature Equipment:Used in high-temperature reaction vessels, furnace tubes, and other equipment.

- Electronic Components:Widely used in electronic ceramic substrates, insulation materials, and other electronic applications.

- Chemical Industry:Applied as a corrosion-resistant material in chemical pipelines, reactors, and other equipment.

- Mechanical Manufacturing:Used to produce highly wear-resistant parts such as bearings, seals, and other components.

- Aerospace:Used as thermal insulation material and protective components in high-temperature environments.

| Property | Unit | ZTA | YIZ |

| Bulk Density | g/cm³ | 3.8-4.6 | 6 |

| Hardness | MPa ≥ | 86-88 | 88-90 |

| Flexural Strength | HRA ≥ | 172-450 | 900 |

| Max Operating Temp | °C | 1400-1500 | 1500 |

| Thermal Expansion | ×10⁻⁶/℃ | - | - |

| Dielectric Constant | tr (20℃, 1 MHz) | - | - |

| Dielectric Loss | tanδ ×10⁻⁴ (1 MHz) | - | - |

| Volume Resistivity | cm (20℃) | 10¹³ | 10¹⁴ |

| Breakdown Strength | KV/mm, DC ≥ | - | - |

| Acid Resistance | mg/cm² ≤ | - | - |

| Alkali Resistance | mg/cm² ≤ | - | - |

| Wear Resistance | g/cm² ≤ | - | - |

| Compressive Strength | MPa ≥ | 2300-2900 | 2500 |

| Flexural Strength | MPa ≥ | - | - |

| Elastic Modulus | GPa | - | - |

| Poisson's Ratio | (Lateral Strain Coefficient) | - | - |

| Thermal Conductivity | W/m·K (20℃) | 13-27 | 22 |

new material

new material