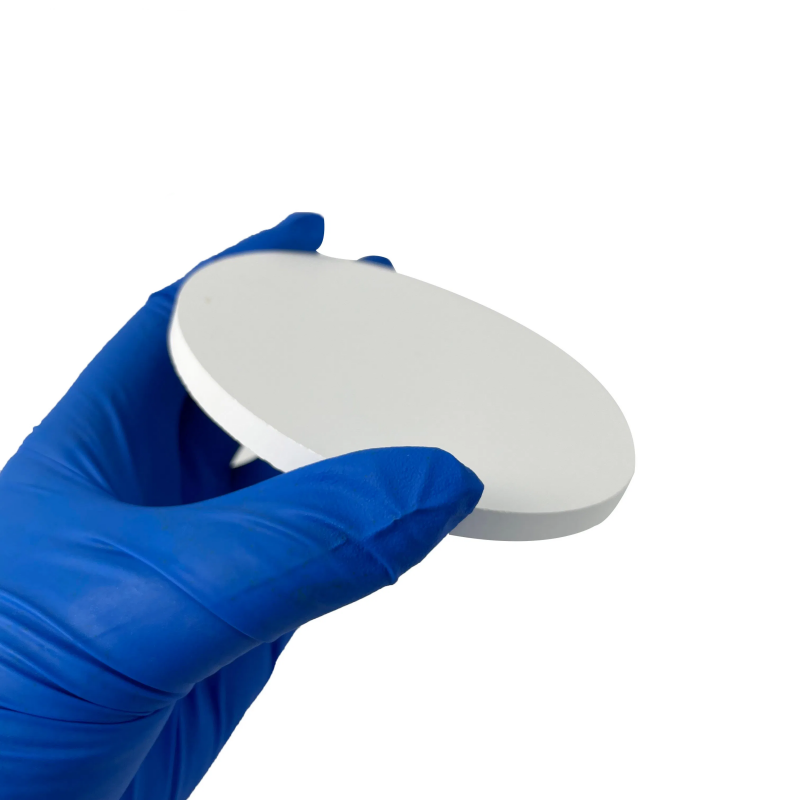

Zirconium dioxide (ZrO₂) ceramic sputtering targets offer high-purity composition, optimized thermal stability, and excellent mechanical durability. Designed for thin-film deposition applications, they ensure reliable coating performance, extended lifespan, and precision-controlled material transfer.

Product Overview

Zirconium dioxide ceramic sputtering targets are high-purity white crystalline zirconia materials, known for their exceptional high-temperature stability and chemical inertness. With a melting point of 2715°C and a boiling point of 4300°C, these targets are widely used in thin-film deposition technologies, especially for applications requiring superior high-temperature and corrosion-resistant properties.

Key Features

- High Melting and Boiling Points: Excellent high-temperature resistance.

- Outstanding Chemical Stability: Suitable for extreme environments.

- High Purity (99.95%): Ensures superior performance and extended lifespan.

- Excellent Corrosion and Wear Resistance: Offers durability in demanding conditions.

Applications

Zirconium dioxide ceramic sputtering targets are used in various industries:

- Thin-Film Deposition: Widely used in fuel cells, semiconductors, LED displays, photovoltaic devices, and other thin-film applications.

- Glass Coating: For enhancing the protection and performance of glass surfaces.

- Pigment Protection: Used as a protective coating for titanium dioxide pigment particles.

- Refractory Materials: Serves as an essential refractory material in high-temperature and corrosive environments.

- Abrasives and Enamel: Used in abrasives and enamel coatings.

- Electronics and Insulating Materials: Applied in the manufacture of electronic components and insulating materials.

new material

new material