Zirconia ceramic positioning rods offer exceptional wear resistance, optimized mechanical stability, and superior precision alignment. Designed for industrial applications, they ensure reliable positioning, extended durability, and high-performance efficiency in demanding environments.

Product Overview:

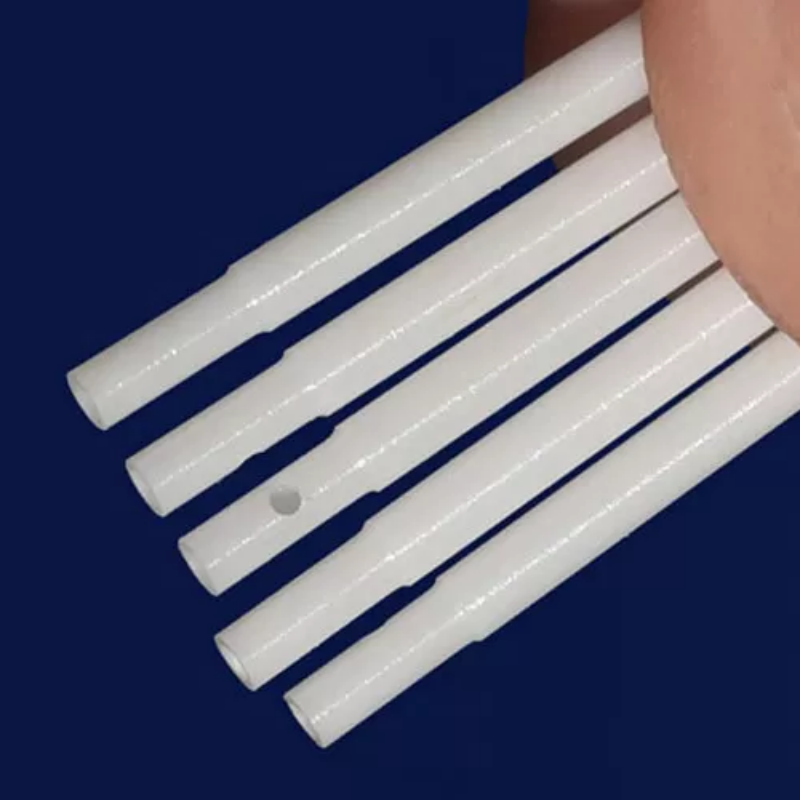

Zirconia ceramic positioning rods are made from high-purity zirconia material, offering exceptional density, strength, and toughness. These rods are widely used in precision instruments and demanding industrial environments. The manufacturing process ensures even wear from surface to interior, offering outstanding wear resistance and high-precision tolerance machining. These rods are ideal for reducing processing losses and lowering overall usage costs in precision equipment.

Product Features:

- High Density and High Fracture Toughness:The high density and fracture toughness ensure long-term stability and reliable use in complex and high-load conditions.

- High Hardness and Excellent Wear Resistance:The superior hardness and wear resistance significantly reduce wear during use, extending service life and lowering overall costs.

- Corrosion Resistance and High-Temperature Resistance:These rods offer excellent resistance to acid, alkali corrosion, and high temperatures, making them suitable for harsh working environments.

- High Precision Tolerance Machining:With high-precision tolerance machining capabilities, these rods can achieve mirror polishing, ensuring they meet the stringent accuracy requirements of demanding applications.

Applications:

Zirconia ceramic positioning rods are widely used in the following fields:

- Precision Instrument Testing:Used for positioning and supporting precision instruments to ensure equipment stability and accuracy.

- Ultrafine Grinding Equipment:Ideal for fine chemicals and nanomaterials grinding, providing high-efficiency performance.

- Electronics and Semiconductor Industry:Applied in the precise processing and testing of electronic pastes, semiconductors, and new energy materials.

- Medical Devices:Used in high-precision components of medical devices to ensure strict quality control and reliability.

- Aerospace and Machinery Manufacturing:Provides durability and precision positioning in high-end industrial fields such as aerospace and machinery manufacturing.

- Fiber Optic Connectors and Battery Materials:Suitable for precision manufacturing in fiber optic connectors, battery materials, and other critical components, ensuring stable equipment performance.

| Performance | Unit | Typical Value |

| Density | g/cm³ | >6.0 |

| HV Hardness | Kg/mm² | >1300 |

| Compressive Strength | MPa | 5500 |

| Flexural Strength | MPa | 1250 |

| Modulus of Elasticity | GPa | 200 |

| Thermal Conductivity | W/(m·K) | 3 (20-400℃) |

| Thermal Expansivity Coefficient | 10⁻⁶K⁻¹ | 9.6 |

| Fracture Toughness | MPa·m⁰.⁵ | 8 |

| Grain Size | μm | 0.5 |

new material

new material