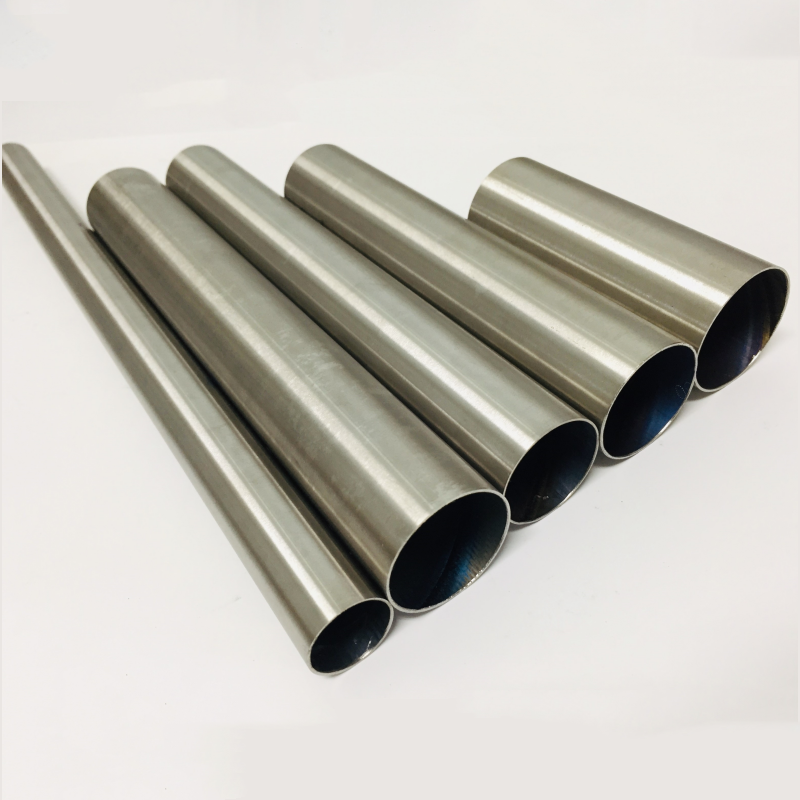

Product Overview

Titanium tubes are high-purity titanium metal tubes manufactured using advanced production techniques. They offer outstanding mechanical properties and excellent corrosion resistance. With a density of 4.506 g/cm³, a melting point of 1668°C, and a boiling point of 3287°C, titanium tubes maintain exceptional performance even in high-temperature and harsh environments. These tubes are widely used in aerospace, chemical, medical, and military industries, especially in applications requiring high strength, corrosion resistance, and heat resistance.

Key Features

- High Purity: Titanium tubes have a purity of 4N-5N, ensuring stability and high performance under demanding conditions.

- Heat and Corrosion Resistance: Titanium's excellent heat and corrosion resistance allows it to withstand the effects of seawater, air, strong acids, and alkalis.

- Lightweight and High Strength: Titanium tubes have a low density but high strength, making them ideal for applications where weight and strength are critical.

- Good Machinability: Titanium tubes exhibit excellent plasticity and machinability, especially at high purities, allowing them to meet complex processing requirements.

Applications

- Aerospace: Titanium tubes are widely used in jet engines, spacecraft, missiles, and other aerospace applications due to their ability to withstand high temperatures, low temperatures, and extreme environmental pressures.

- Military: Titanium alloy tubes are used in weapon systems, such as automatic rifles, mortar bases, and other combat equipment, offering excellent strength and toughness.

- Chemical and Petroleum Industry: Due to titanium’s corrosion resistance, titanium tubes are commonly used in chemical equipment, petroleum pipelines, and reactors, improving the lifespan and stability of equipment.

- Medical: Titanium tubes are used in medical devices and implants, such as orthopedic instruments, prosthetics, and dental equipment, ensuring long-term stability within the body.

- Other Industries: Titanium tubes are also used to manufacture high-pressure vessels, heat exchangers, and other products that require materials with high strength and corrosion resistance.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | <0.005 | ppm | Zn | <0.02 | ppm | Pb | <0.01 | ppm | |||

| B | <0.01 | ppm | Ga | <0.05 | ppm | Bi | <0.01 | ppm | |||

| F | <0.05 | ppm | Ge | <0.005 | ppm | Tm | <0.05 | ppm | |||

| Na | <0.01 | ppm | As | 0.03 | ppm | Th | <0.0001 | ppm | |||

| Mg | 0.06 | ppm | Se | <0.05 | ppm | Er | <0.005 | ppm | |||

| Al | 0.11 | ppm | Zr | <0.05 | ppm | Ru | <0.01 | ppm | |||

| Si | 0.24 | ppm | Nb | <0.2 | ppm | Rh | <0.05 | ppm | |||

| P | <0.01 | ppm | Mo | <0.05 | ppm | Os | <0.01 | ppm | |||

| Cl | 0.23 | ppm | Pd | <0.01 | ppm | Cd | <0.05 | ppm | |||

| K | <0.01 | ppm | Ag | <0.02 | ppm | In | <0.05 | ppm | |||

| Ca | <0.2 | ppm | Sn | <0.05 | ppm | ||||||

| Ti | Matrix | wt% | Sb | <0.05 | ppm | ||||||

| V | 0.02 | ppm | Ba | <0.005 | ppm | ||||||

| Cr | 0.06 | ppm | Hf | <0.01 | ppm | ||||||

| Mn | 0.05 | ppm | Ta | source | ppm | C | <5 | ppm | |||

| Fe | 3.2 | ppm | W | <0.01 | ppm | S | 0.02 | ppm | |||

| Co | <0.01 | ppm | Pt | <0.05 | ppm | O | 250 | ppm | |||

| Ni | 0.24 | ppm | Au | <0.05 | ppm | N | 5 | ppm | |||

| Cu | 0.28 | ppm | Hg | <0.1 | ppm | H | <1 | ppm |

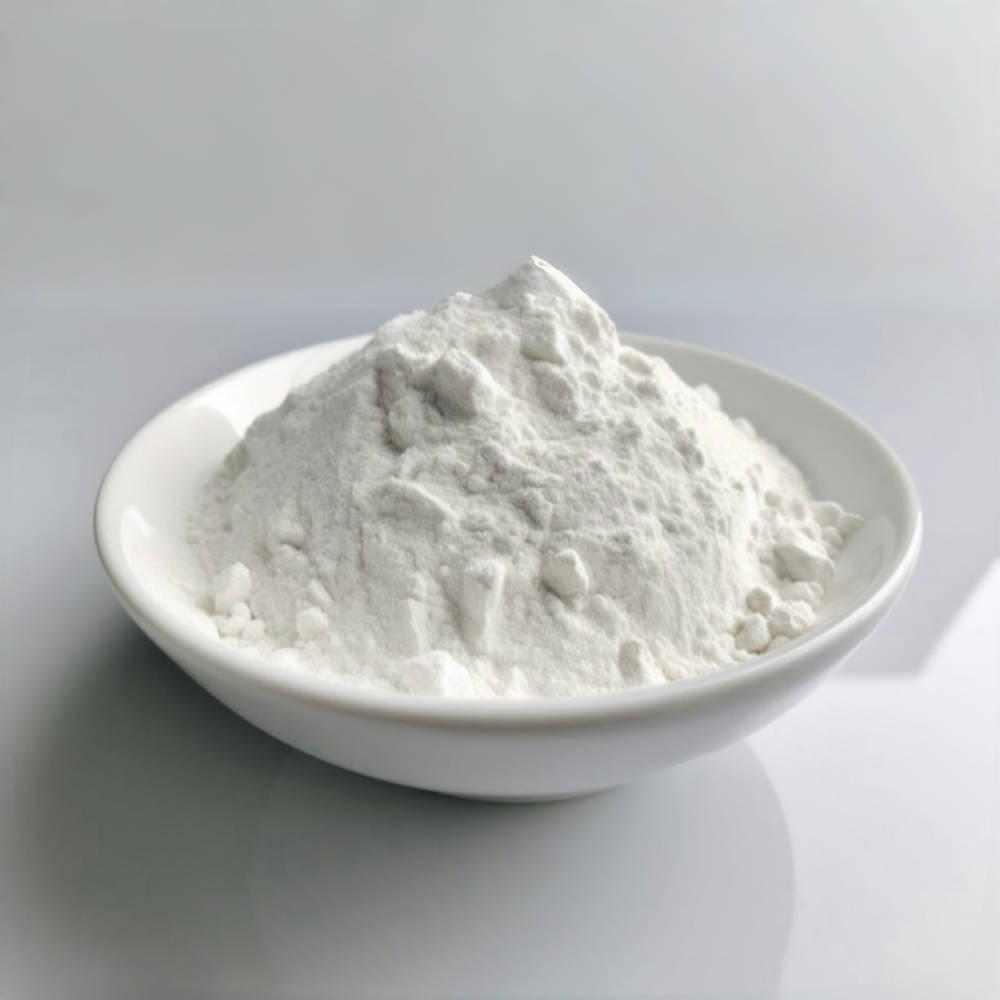

new material

new material