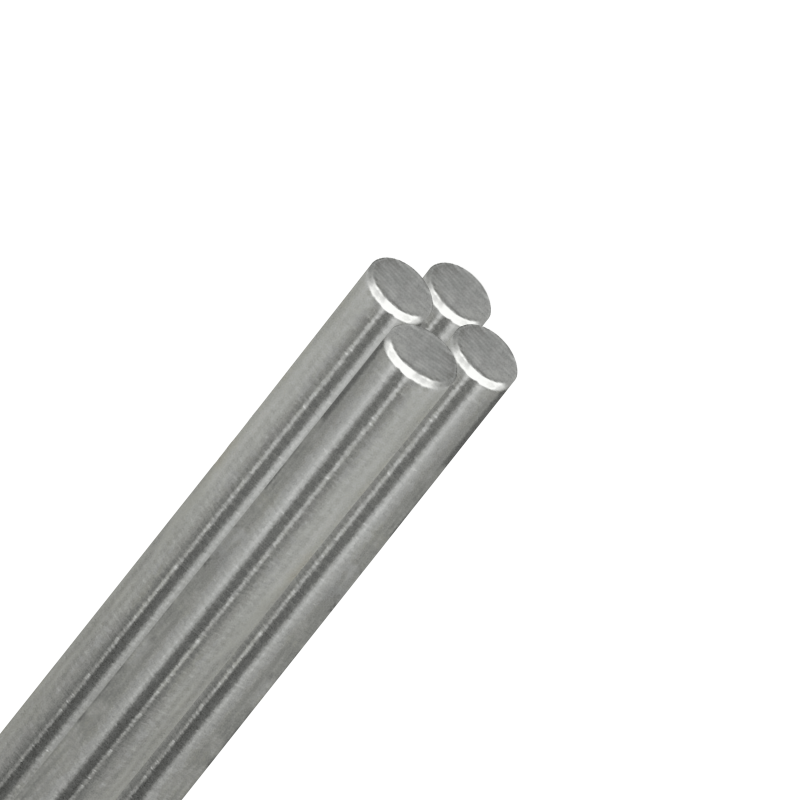

Tin rods are high-purity materials used in various industrial applications, including electronics, soldering, and alloy production. They are known for their excellent corrosion resistance, high malleability, and unique properties.

Product Overview

High-purity tin rods are made from metallic tin, which is soft and flexible, with a melting point of 231.89°C and a density of 7.29 g/cm³. The purity of these rods ranges from 4N to 7N, making them suitable for various industrial applications. Custom specifications can be provided upon request.

Key Features

- High Purity:Ensures efficient performance in the electronics and chemical industries.

- Easy to Process:Good flexibility makes it suitable for a variety of processing and welding requirements.

- Oxidation Resistant:Maintains its shine and resists oxidation in air.

Applications

- Electronics Industry:Widely used in the manufacturing and soldering of electronic components.

- Alloy Manufacturing:Essential for producing babbitt alloys, tin foil, and other alloy materials.

- Friction Materials:Serves as a component in oil-impregnated bearings and powder metallurgy materials.

- Chemical Industry:Used as a high-purity reagent in chemical compounds and organic synthesis.

- Decorative Uses:Compounds of tin and sulfur can be applied as gold-colored pigments for decorative purposes.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | <5 | ppm | Pb | 5 | ppm | |||||

| B | Ga | Bi | 5 | ppm | |||||||

| F | Ge | Y | |||||||||

| Na | As | <5 | ppm | Th | |||||||

| Mg | Se | Er | |||||||||

| Al | 5 | ppm | Zr | Ru | |||||||

| Si | Nb | Rh | |||||||||

| P | Mo | Os | |||||||||

| Cl | Pd | Cd | <5 | ppm | |||||||

| K | Ag | 23 | ppm | In | |||||||

| Ca | Sn | Matrix | wt% | ||||||||

| Ti | Sb | <5 | ppm | ||||||||

| V | Ba | ||||||||||

| Cr | ppm | Hf | |||||||||

| Mn | Ta | C | |||||||||

| Fe | 12 | ppm | W | S | <5 | ppm | |||||

| Co | Pt | O | |||||||||

| Ni | 5 | ppm | Au | N | |||||||

| Cu | 5 | ppm | Hg | H |

new material

new material