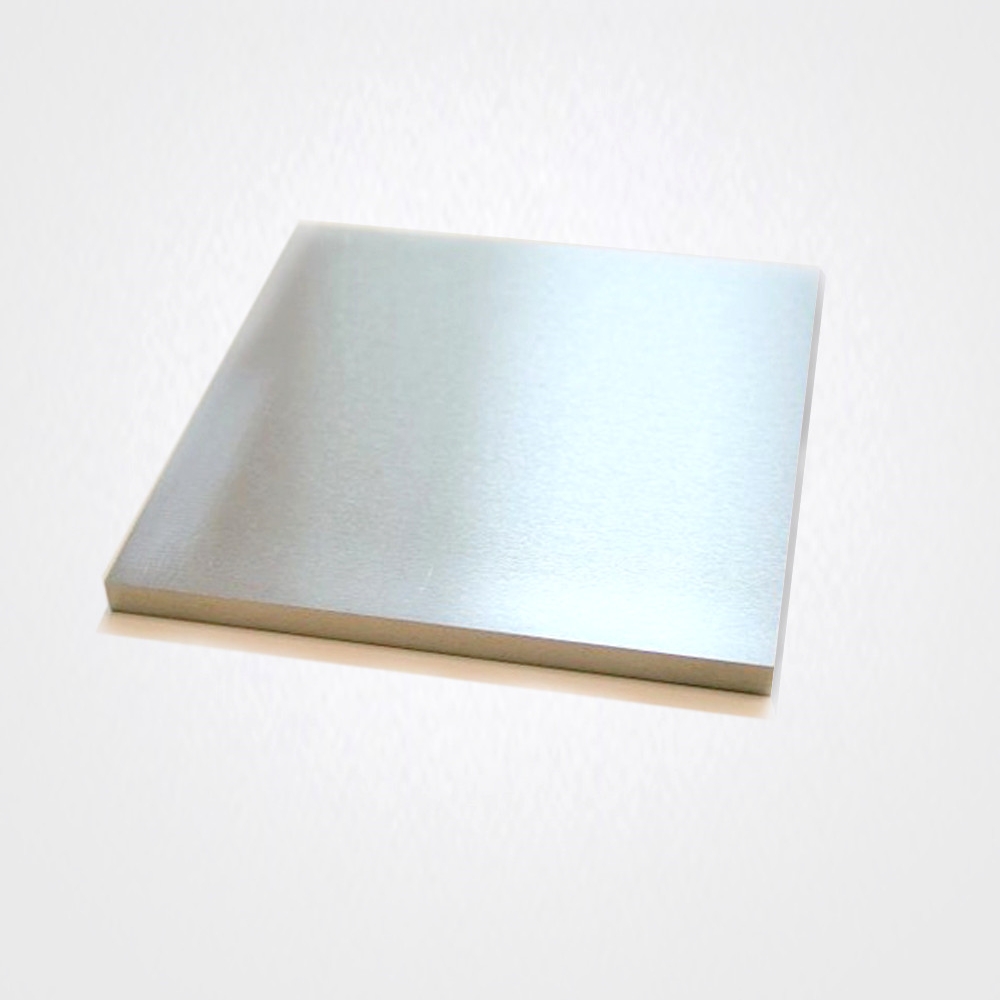

Product Overview

Tantalum plates are made from high-purity tantalum material, offering exceptional high-temperature and corrosion resistance. These plates are typically used in applications requiring high strength, resistance to corrosion, and the ability to withstand extreme temperatures. Tantalum plates are widely used across industries such as chemicals, electronics, aerospace, and military applications.

Features

- High Melting Point: Tantalum has a high melting point of 2996°C, providing excellent stability in high-temperature environments

- Corrosion Resistance: Highly resistant to a wide range of acidic and alkaline substances, making it ideal for harsh chemical environments

- Excellent Ductility: Tantalum’s excellent ductility allows it to be processed into various sizes and shapes to meet diverse application requirements

- Low Thermal Expansion Coefficient: The low thermal expansion coefficient makes tantalum suitable for high-precision equipment and high-temperature applications

- High Toughness: Tantalum is tougher than copper, making it ideal for high-strength environments that require resistance to impact and fatigue

Applications

Tantalum plates have a wide range of applications, particularly in the following fields:

- Chemical Industry: Tantalum plates can replace stainless steel in environments involving strong acids, alkalis, and corrosive media, with a service life several times longer than standard stainless steel

- Electronics Industry: Tantalum plates play an important role in manufacturing high-performance capacitors, electronic components, and other critical electronic devices

- Aerospace: Due to its outstanding high-temperature performance, tantalum plates are commonly used in spacecraft components and thermal shielding materials

- Military: Tantalum plates are used in the manufacture of missiles, military equipment, and ammunition, offering high strength and high-temperature resistance

- Nuclear and High-End Manufacturing: Tantalum plates are widely used in nuclear energy, power generation, and high-end material processing due to their high-temperature and corrosion resistance

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | Se | Er | |||||||||

| Al | <5 | ppm | Zr | Ru | |||||||

| Si | 10 | ppm | Nb | 200 | ppm | Rh | |||||

| P | Mo | 20 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | <5 | ppm | Sb | ||||||||

| V | <5 | ppm | Ba | ||||||||

| Cr | ppm | Hf | 10 | ppm | |||||||

| Mn | Ta | Matrix | wt% | C | 15 | ppm | |||||

| Fe | 10 | ppm | W | 28 | ppm | S | |||||

| Co | Pt | O | 80 | ppm | |||||||

| Ni | <5 | ppm | Au | N | 20 | ppm | |||||

| Cu | Hg | H | 2 | ppm |

new material

new material