Synthetic quartz material is a high-purity, artificially grown silica crystal engineered for superior optical clarity, extreme thermal stability, and exceptional mechanical durability. Manufactured through precision-controlled growth processes, it offers excellent resistance to environmental stress, minimal thermal expansion, and enhanced chemical stability. This advanced material is widely used in semiconductor fabrication, precision optics, metrology instruments, and aerospace applications, ensuring consistent performance in high-demand environments.

Product Overview

Synthetic quartz material is made from high-purity SiCl4 as the raw material and produced using a hydrogen-oxygen flame fusion process, ensuring the product is bubble-free with excellent optical performance. This material features outstanding transparency, low impurity content, and stable physical properties, making it widely used in high-end optical fields such as precision optical components, optical instruments, and optical equipment.

Key Features

- Bubble-Free: Produced using advanced fusion technology, ensuring the quartz material is free of bubbles, maintaining the purity of its optical performance.

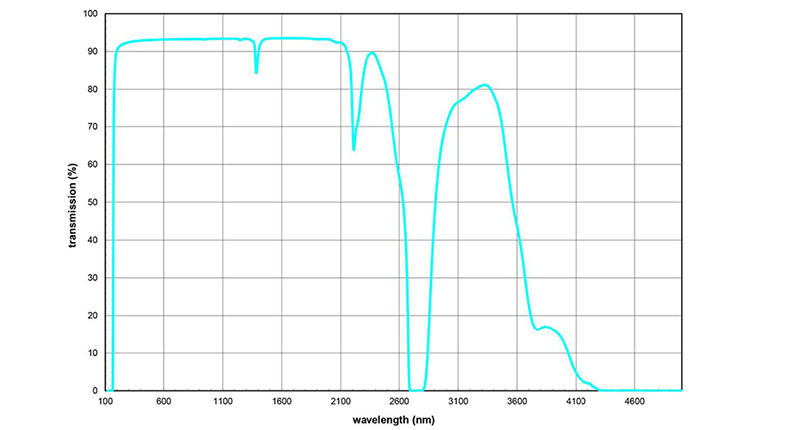

- Excellent Optical Properties: Offers outstanding transparency and superior optical transmission, ideal for high-precision optical applications.

- High Purity: Made from high-purity SiCl4 and refined manufacturing processes to ensure material purity and stability.

- Strong Stability: The material demonstrates excellent thermal and physical stability in various environments, making it suitable for demanding working conditions.

Applications

- High-End Optics: Widely used in precision optical components, lenses, fibers, and other high-accuracy optical devices.

- Optical Instruments: Used as key components in high-performance optical instruments, providing excellent optical transmission and precise imaging.

- Optical Equipment: Used in various precision optical devices to ensure accurate light control and transmission.

- Precision Optical Manufacturing: Ideal for the production of optical components that require high optical purity and precision processing.

| Element | Content (ppm) |

| Aluminum (Al) | < 0.05 |

| Calcium (Ca) | < 0.02 |

| Copper (Cu) | < 0.005 |

| Iron (Fe) | < 0.005 |

| Titanium (Ti) | < 0.01 |

| Manganese (Mn) | < 0.01 |

| Potassium (K) | < 0.01 |

| Sodium (Na) | < 0.02 |

| Hydroxyl (OH) | 900 - 1300 |

| Mechanical Properties | Value |

| Density | 2.2 g/cm鲁 |

| Young's Modulus | 74 GPa |

| Poisson's Ratio | 0.17 |

| Bending Strength | 65 MPa |

| Compressive Strength | 1300 MPa |

| Tensile Strength | 49 MPa |

| Torsional Strength | 29 MPa |

| Mohs Hardness | 6~7 |

| Electrical Properties | Value |

| Dielectric Constant | 3.7 |

| Dielectric Loss | 0.0002 |

| Resistivity | 1×10¹⁶ Ω·cm |

| Thermal Properties | Value |

| Strain Point | 1070 ℃ |

| Annealing Point | 1150 ℃ |

| Softening Point | 1670 ℃ |

| Thermal Conductivity | 1.24 W/m·K (20℃) |

| Specific Heat | 749 J/kg·K |

| Thermal Diffusivity | 7.5 × 10⁻⁷ m²/s |

| Thermal Expansion Coeff. | 5.2 - 5.8 × 10⁻⁷/K (25℃~320℃) |

new material

new material