Silicon Carbide (SiC) pellets are high-purity materials used in various industrial applications, including electronics, abrasives, and refractory materials. They are known for their excellent thermal conductivity, high melting point, and unique properties.

Product Overview

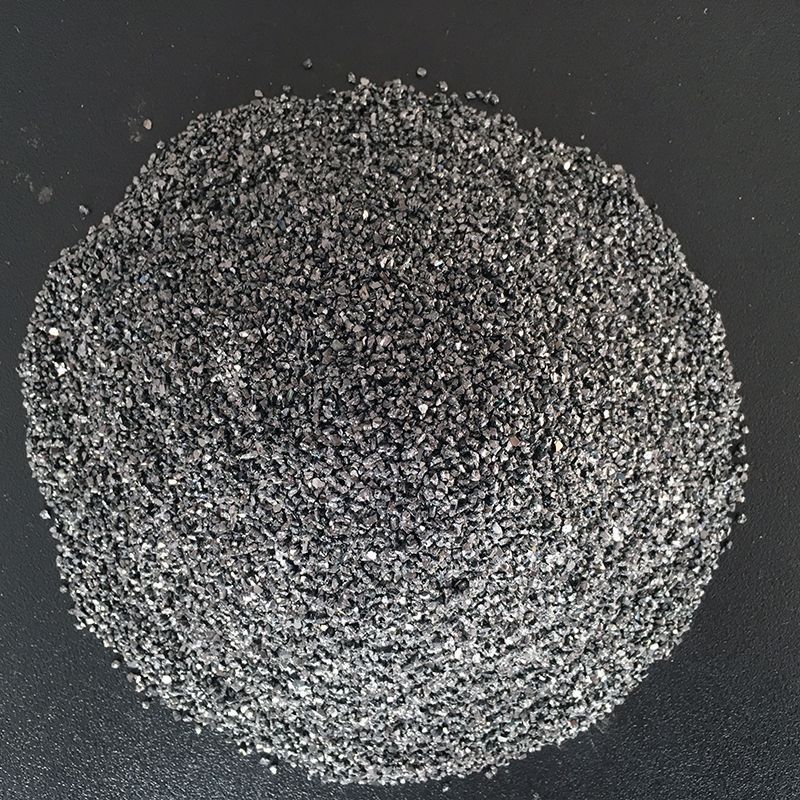

Silicon carbide (SiC) pellets are compounds made from silicon and carbon, offering exceptional hardness and wear resistance with a Mohs hardness of 9. These pellets are widely used in environments requiring high abrasion resistance, high-temperature stability, oxidation resistance, and chemical corrosion resistance. The product features a rainbow-colored crystalline appearance, making it suitable for use in extreme conditions. Its superior physical and chemical properties make it a popular choice across various industrial sectors.

Key Features

- Extreme Hardness: Mohs hardness of 9, suitable for high-wear, high-strength applications.

- High-Temperature Resistance: Stable performance even in high-temperature environments.

- Oxidation and Corrosion Resistance: Outstanding performance in harsh chemical environments.

- Multiple Forms: Available in both pellets and block forms, with customizable specifications based on requirements.

Applications

- Abrasives and Grinding Materials: Widely used in sandblasting, coating abrasives, ceramics, and grinding wheels.

- Refractory Materials: Ideal for metallurgy and the manufacturing of refractory materials due to its excellent high-temperature properties.

- Filtration and Insulation: Utilized as filtration media and insulation materials.

- Engineering and Manufacturing: Used in the production of wire saws, wear-resistant materials, and other durable products.

- Coatings and Anti-Slip: Commonly applied in floor coatings, anti-slip surfaces, and decorative coatings.

new material

new material