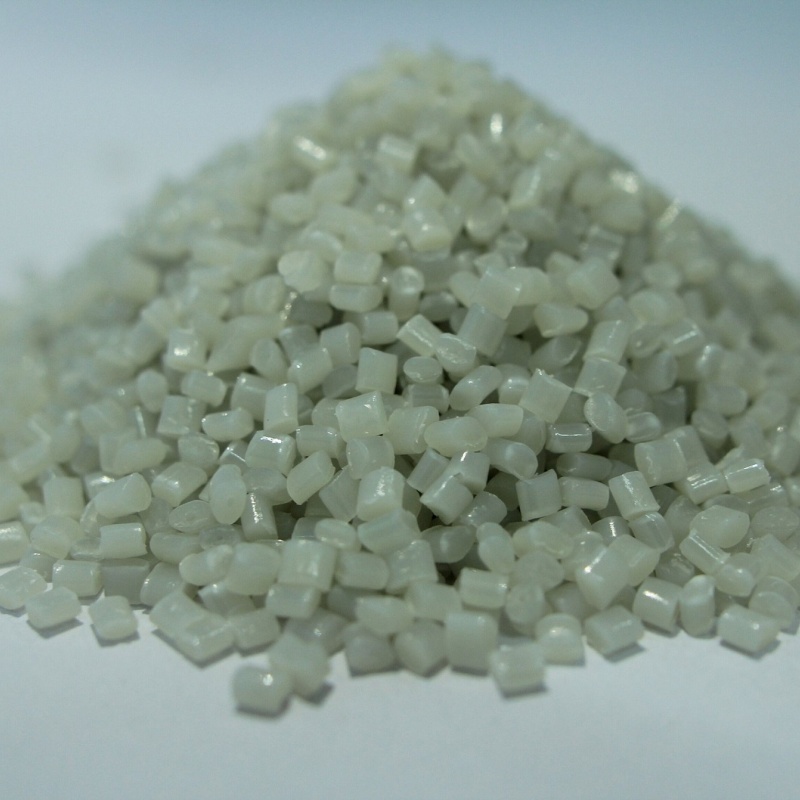

RPC/ABS Alloy (Polycarbonate/ABS Alloy) combines the strength of polycarbonate with the flexibility of ABS, offering superior impact resistance, excellent thermal stability, and enhanced durability. Designed for automotive, electrical, and industrial applications, it ensures long-term reliability and efficient processing.

Product Description:

RPC/ABS Alloy is a high-performance material that combines the advantages of polycarbonate (PC) and acrylonitrile-butadiene-styrene copolymer (ABS). It features high heat resistance, high mechanical strength, and good flowability. This material is widely used in automotive interior materials, consumer electronics, and other applications. It provides a matte surface effect that reduces visual fatigue during driving and enhances overall aesthetics. With the use of coating-free technology, RPC/ABS alloy not only reduces production costs but also minimizes environmental pollution.

Product Features:

- Matte Finish:Excellent surface gloss that effectively reduces visual fatigue, especially suitable for automotive interior components and other parts that are used for extended periods.

- High Heat Resistance:Exceptional high-temperature resistance ensures that the alloy remains stable even in high-temperature environments.

- High Mechanical Strength:Offers excellent impact strength and overall mechanical properties, ideal for withstanding friction and impact in daily use.

- Easy Processing and Molding:Good flowability makes it easy to process and adapt to various molding techniques.

- Environmentally Friendly:Coating-free technology reduces harmful emissions during the production process, complying with environmental standards.

- Customizable Colors:Can be colored according to customer requirements, meeting personalized design needs.

Applications:

- Automotive Industry:Used for automotive interior parts such as dashboards, door panels, and other components, offering both aesthetic appeal and comfort.

- Consumer Electronics:Suitable for products like smartphone cases, TV housings, home appliance housings, providing durability and aesthetics.

- Electronics:Used for the housings of high-end electronic devices, offering excellent impact resistance and chemical stability.

- Other Industries:Suitable for any field requiring high strength, heat resistance, and a visually appealing surface finish.

| Property | Test Method (ISO) | Unit | Matt PC/ABS Alloy |

| Melt Flow Rate | 1133 | g/10min | 14 |

| Density | 1183 | g/cm³ | 1.14 |

| Tensile Strength | 527 | MPa | 50 |

| Elongation | 527 | % | 100 |

| Flexural Strength | 178 | MPa | 75 |

| Flexural Modulus | 178 | MPa | 2300 |

| Notched Impact (Charpy) | 179 | KJ/m² | 40 |

| Notched Impact (Izod) | 180/1A | KJ/m² | 40 |

| Heat Deflection Temperature | 75/A | ℃ | 90 |

| Flame Resistance | UL-94 | / | 1.5mm HB |

| Shrinkage Rate | 294 | % | 0.4-0.7 |

new material

new material