Reforming oil catalytic olefin removal catalyst is a high-performance catalytic material designed for the selective removal of olefins from reformate streams, ensuring enhanced fuel stability and improved product quality. Engineered with optimized metal-supported formulations, it enhances reaction kinetics, improves selectivity, and ensures prolonged operational lifespan for industrial applications. This catalyst is widely used in petrochemical refining, gasoline upgrading, and aromatic hydrocarbon processing, delivering reliable performance for continuous catalytic olefin removal.

Product Overview:

The Reforming Oil Catalytic Olefin Removal Catalyst uses advanced molecular sieve technology and is a mature aromatics refining technique, capable of replacing traditional clay catalysts. It is widely applied in the refining process of reforming oils. The catalyst utilizes the shape-selective properties of the molecular sieve and its solid acidity to remove olefins efficiently, showing excellent adsorption capacity and reactivity.

Key Features:

- High Activity:The catalyst has a much higher activity compared to traditional clay catalysts, significantly improving reaction rates and product yields.

- Long Single-Cycle Lifetime:The NKC-17 catalyst offers a longer single-cycle lifetime than clay, with product quality remaining almost unchanged.

- Recyclable:The catalyst can be regenerated multiple times. After regeneration, its performance recovers to about 95% of its fresh state.

- Low Operating Cost:The catalyst operates at lower temperatures for extended periods, achieving high olefin removal rates, protecting the adsorbent, and reducing energy consumption during the production process.

- No Equipment Modification Required:The catalyst can directly replace traditional clay in existing aromatics refining units, without the need for equipment modifications or adjustments to the operational process.

Applications:

- Aromatics Refining:Widely used in the petroleum refining and chemical industries, particularly in the process of olefin removal from reforming oil.

- Oil Refining:Replaces traditional clay to improve oil quality and reduce olefin content.

- Catalytic Cracking and Reforming:Applied in catalytic cracking units and aromatics refining equipment to enhance reaction efficiency and extend catalyst lifespan.

| Item | Data | Method |

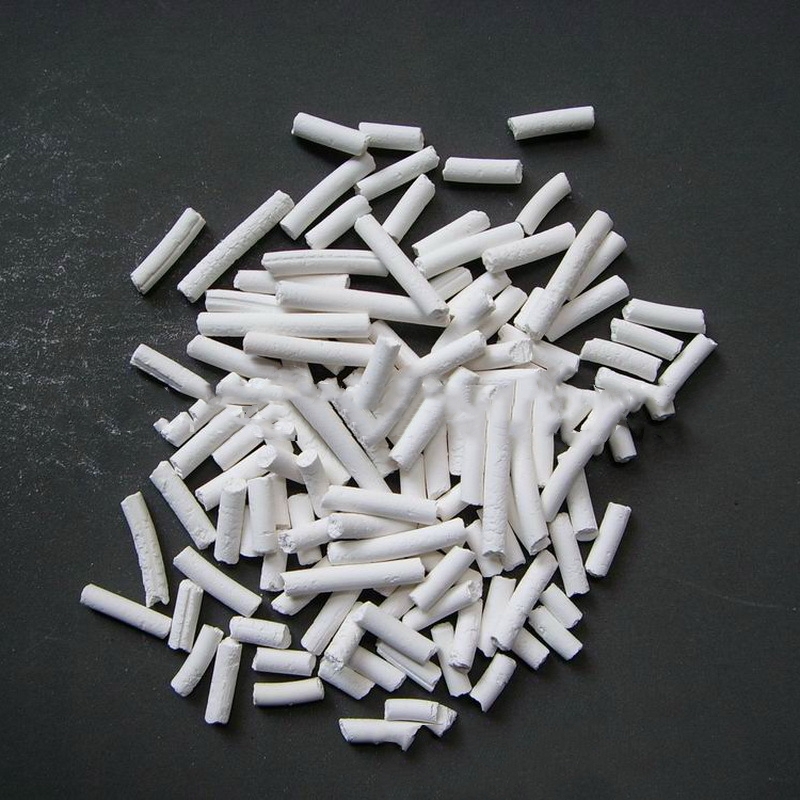

| Colour | White | / |

| Shape | Cylinder | / |

| Diameter (mm) | 1.8~2.2 | Caliper measurement (20 grains) |

| Length (mm) | 3~10 | Caliper measurement (20 grains) |

| Pore Volume (ml/g) | ≥0.36 | BET |

| Surface Area (BET) m²/g | ≥580 | BET |

| Compressive Strength (N/cm) | ≥110 | Intensity meter |

| Bulk Density (g/cm³) | 0.60~0.70 | Cylinder method |

| Crushing Degree (m/m %) | ≤0.5 | / |

new material

new material