Fluorinated carbon nanotubes (FCNTs) offer enhanced chemical stability, optimized surface reactivity, and superior electrical conductivity. Designed for advanced applications, they enable efficient functionalization, extended durability, and high-performance adaptability.

Product Overview

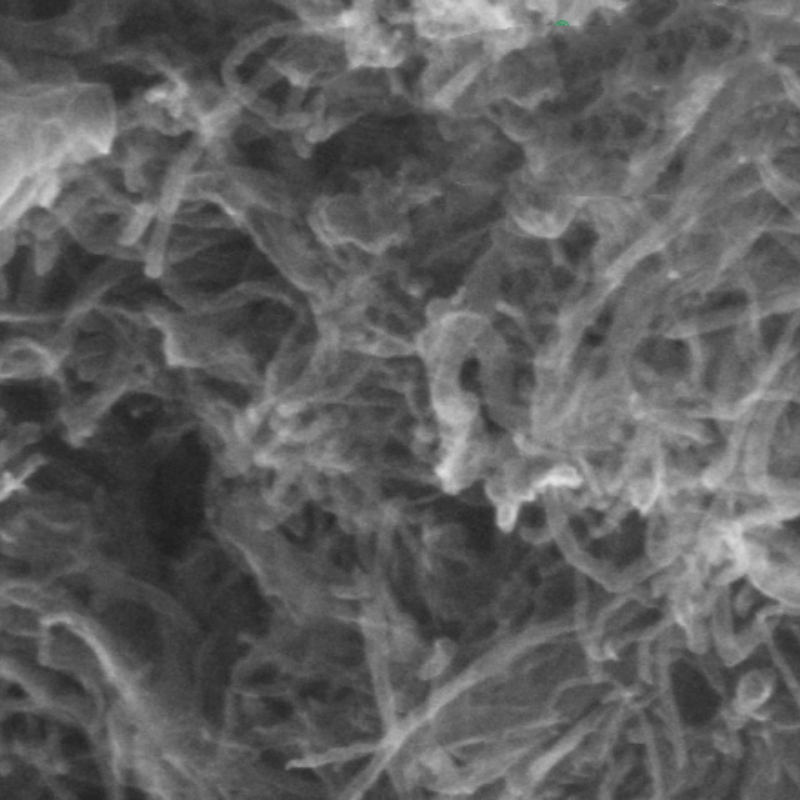

Fluorinated carbon nanotubes are produced by fluorinating the surface of conventional carbon nanotubes (CNTs). During the fluorination process, some or all of the carbon atoms on the CNT surface are replaced by fluorine atoms, significantly enhancing their chemical stability. Fluorinated carbon nanotubes offer improved corrosion resistance, making them suitable for use in harsh chemical environments. This fluorination process also alters their electrical properties, typically reducing conductivity, but this change may offer unique advantages for certain specific applications.

Key Features

- Enhanced Chemical Stability:Fluorinated carbon nanotubes exhibit stronger corrosion resistance, making them ideal for harsh chemical environments.

- Improved Wettability and Dispersion:Fluorination improves surface wettability and dispersion in solvents, facilitating further processing.

- Unique Thermal Properties:Fluorinated carbon nanotubes may possess excellent thermal conductivity and stability, suitable for thermal management applications.

- Good Mechanical Properties:Retains the high strength and modulus of the original carbon nanotubes, enhancing the mechanical properties of composite materials.

- Versatile Surface Functionalization:Can be further chemically modified to expand their application potential.

Applications

- Solid Lubricants:Fluorinated carbon nanotubes exhibit excellent lubricating properties, widely used in precision machinery and aerospace applications.

- Composite Materials:When combined with resins, ceramics, and other materials, they significantly enhance the mechanical properties and functionality of composite materials.

- Corrosion-Resistant Coatings:Due to their superior chemical stability, fluorinated carbon nanotubes are used in the production of anti-corrosion coatings to protect materials from degradation.

| Technical Parameter | Value |

| Tube Diameter | 20-30 nm |

| Tube Length | 2-10 µm |

| Purity | ~90 at% |

new material

new material