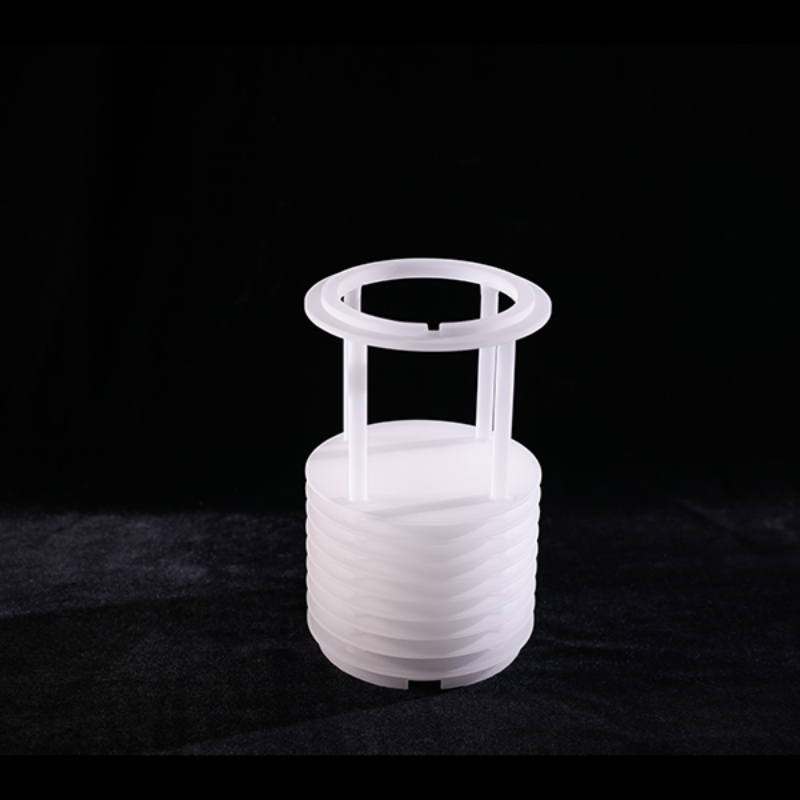

Quartz insulation barrel is a high-performance thermal-resistant component designed for extreme-temperature applications requiring superior insulation and mechanical durability. Manufactured from high-purity quartz, it offers excellent thermal stability, low thermal expansion, and strong resistance to chemical and environmental stress. This specialized material is widely used in semiconductor processing, high-temperature furnaces, aerospace applications, and scientific research, ensuring reliable thermal insulation and structural integrity in demanding environments.

Product Overview

The Quartz Insulation Barrel is made from high-purity quartz materials and offers exceptional high-temperature resistance and thermal insulation properties. It effectively maintains stable internal temperatures, making it ideal for high-precision temperature control and thermal processing in the semiconductor industry. The barrel's excellent chemical stability and corrosion resistance allow it to withstand harsh environments, ensuring long-term, reliable performance in various semiconductor manufacturing processes.

Key Features

- High Purity Materials: Made with high-purity quartz to ensure product stability and efficient thermal insulation performance.

- High-Temperature Resistance: Capable of withstanding extreme temperatures, suitable for the high-temperature requirements of semiconductor production.

- Excellent Insulation Properties: Provides efficient insulation, minimizing heat loss and maintaining stable internal temperatures.

- Strong Chemical Stability: Corrosion-resistant, making it ideal for use in diverse chemical environments and ensuring long-term durability.

- Precise Temperature Control: Facilitates precise temperature management during semiconductor manufacturing, ensuring high-quality product output.

Applications

- Semiconductor Industry: Used for high-temperature heating, temperature control, and thermal treatment during semiconductor manufacturing.

- Optical Manufacturing: Provides stable temperature support during the production of optical components.

- Heat Treatment Equipment: Used for temperature control and insulation in high-temperature heat treatment processes.

- Laboratory Applications: Acts as a high-temperature insulation container in research and experimental settings, ensuring precise temperature control.

new material

new material