PVC monomer vinyl chloride production-specific catalyst is a high-performance catalytic material designed to facilitate the selective conversion of ethylene dichloride into vinyl chloride monomer with superior efficiency and stability. Engineered with optimized metal-supported formulations, it enhances reaction kinetics, improves selectivity, and ensures prolonged operational lifespan for industrial applications. This catalyst is widely used in petrochemical refining, polymer precursor manufacturing, and large-scale vinyl chloride monomer production, delivering reliable performance for continuous catalytic conversion.

Product Overview

The ethylene oxychlorination catalyst is a key catalyst used in the production of vinyl chloride monomer (VCM), which is an essential precursor for PVC resin production. This catalyst facilitates the oxychlorination reaction between ethylene and chlorine, efficiently converting ethylene into vinyl chloride monomer. It plays a crucial role in the PVC production process, ensuring high catalytic efficiency and product quality.

Key Features

- High Catalytic Activity: Optimized formulation ensures efficient reaction rates and high-quality product formation.

- Strong Stability: Maintains stable catalytic performance under high temperature and pressure, ensuring prolonged and efficient operation.

- Economic Benefits: Offers a high cost-performance ratio, providing a more affordable alternative to imported catalysts and helping to reduce production costs.

Applications

- VCM Production: Widely used in the production of vinyl chloride monomer (VCM), which is the essential raw material for PVC resin manufacturing.

- PVC Resin Production: Serves as the core catalyst in the PVC production process, extensively used in the synthesis of plastics and resins.

- Chemical Industry: Applicable in the production of other chlorinated chemicals, particularly in the synthesis of ethylene-related chemicals.

| Property Name | Value |

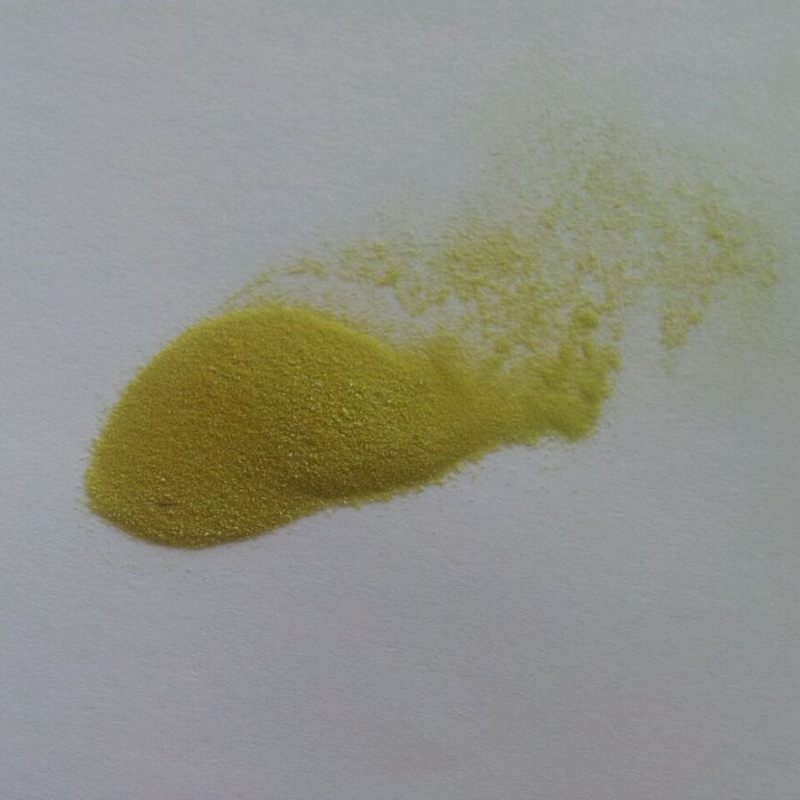

| Appearance | Light yellow microspherical powder |

| Composition | CuCl₂-Al₂O₃ |

| Copper Content (%) | 5±1.0 |

| Specific Surface Area (m²/g) | 120±20 |

| Bulk Density (g/ml) | 1.05±0.1 |

| Pore Volume (ml/g) | 0.25±0.05 |

| Packaging Moisture Content (%) | 1 |

| Particle Size Distribution: | |

| - <90μm | 79-90 |

| - <45μm | 30-50 |

| - <30μm | 8~25 |

| Property Name | Value |

| Reaction Temperature (℃) | 220±5 |

| Reaction Pressure (MPa) | 0.3±0.05 |

| HCl Conversion Rate (%) | >99.5 |

| C₂H₄Cl₂ Purity (%) | >99 |

new material

new material