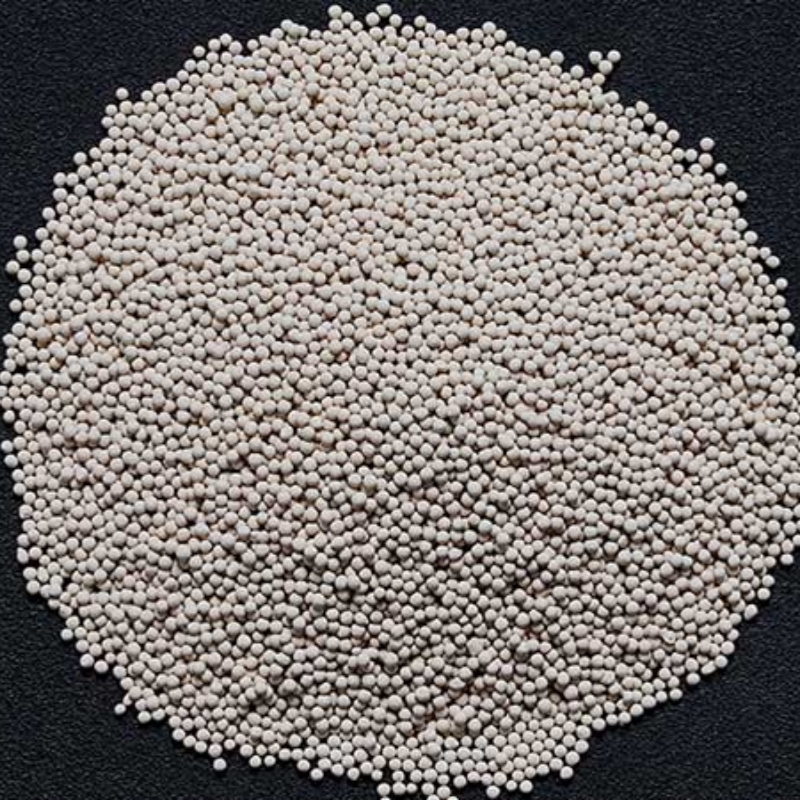

PSA (Pressure Swing Adsorption) molecular sieve is a highly efficient adsorbent material designed for selective gas separation and purification in industrial applications. Featuring an optimized microporous structure, it selectively adsorbs nitrogen while allowing oxygen or hydrogen to pass through, ensuring superior separation efficiency and operational stability. This molecular sieve is widely used in oxygen and hydrogen production, petrochemical refining, air purification, and large-scale industrial gas processing, delivering consistent adsorption performance for continuous PSA operations.

Product Overview

PSA molecular sieves are characterized by high selective adsorption and rapid adsorption speed, making them particularly suitable for gas separation in pressure swing adsorption (PSA) processes. These molecular sieves are ideal for various scales of gas separation units and are widely used in oxygen production, hydrogen production, carbon monoxide concentration, and coal chemical tail gas recovery. They provide stable and efficient performance across a range of gas separation applications.

Key Features

- High Selectivity and Adsorption Speed: Capable of rapidly and efficiently adsorbing the target gases, particularly suitable for PSA systems.

- High Strength and Low Wear: Offers high compressive strength, ensuring long-term stable operation with a low wear rate to extend the service life.

- Low Moisture Content: Maintains a low moisture level in packaging, reducing interference from moisture during use.

Applications

- PSA Hydrogen and Oxygen Production: Widely used in PSA-based hydrogen (PSA-H2) and oxygen (PSA-O2) production systems.

- Gas Concentration and Separation: Used in industrial applications such as carbon monoxide concentration and normal alkane separation.

- Coal Chemical and Tail Gas Recovery: Provides gas separation functionality in coal chemical tail gas recovery and other related fields.

| PSA-H2 | ||

| Parameter Name | Unit | Technical Specification |

| Specification | mm | 1.6-2.4 |

| Static Water Adsorption | wt% | ≥25 |

| CO Adsorption | ml/g | ≥28 |

| N₂ Adsorption | ml/g | ≥10 |

| Bulk Density | Kg/m³ | ≥720 |

| Compressive Strength | N/piece | ≥35 |

| Abrasion Rate | wt% | ≤0.4 |

| Packaging Water Content | wt% | ≤1.5 |

| PSA-O2 | |||

| Parameter Name | Unit | 0.4-0.8mm | 1.6-2.4mm |

| Specification | mm | 0.4-0.8 | 1.6-2.4 |

| Static Water Adsorption | wt% | ≥25 | ≥25 |

| N₂ Adsorption | ml/g | ≥10.8 | ≥10.8 |

| Nitrogen-Oxygen Separation Value | α | ≥3 | ≥3 |

| Compressive Strength | N/piece | ≥35 | ≥35 |

| Bulk Density | Kg/m³ | ≥720 | ≥720 |

| Abrasion Rate | wt% | ≤0.4 | ≤0.4 |

| Packaging Water Content | wt% | ≤1.5 | ≤1.5 |

| Standard | GB/T13550-1992 | GB/T13550-1992 | |

new material

new material