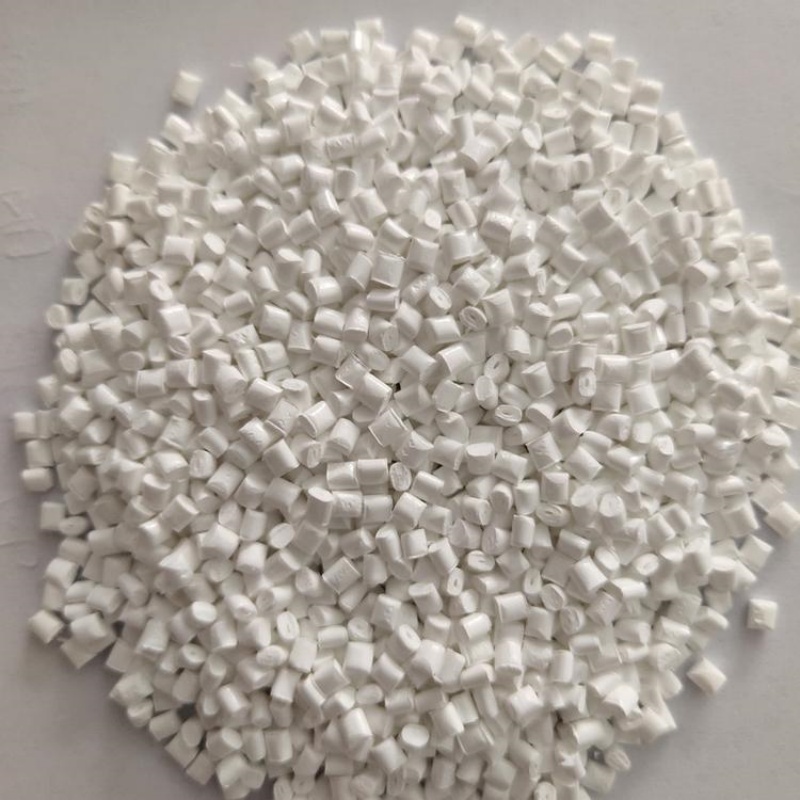

PA66+40GF (40% Glass Fiber Reinforced Polyamide 66) offers exceptional mechanical strength, superior stiffness, and enhanced thermal stability. Designed for automotive, industrial, and structural applications, it ensures long-term durability, precision-engineered performance, and reliable operational efficiency.

Product Overview

PA66+40GF is a polyamide 66 composite material enhanced with high-strength glass fibers, providing exceptional strength and rigidity. This material is ideal for applications requiring high mechanical strength and durability. It demonstrates excellent performance in heavy-duty and high-stress industrial and automotive components, ensuring long-term stability even in harsh environments.

Key Features

- Extremely High Strength: With 40% glass fiber reinforcement, the material offers excellent tensile strength and compressive ability, suitable for high-load and high-pressure applications.

- Outstanding Rigidity: Provides excellent rigidity, making it suitable for applications where shape and dimensional stability are critical.

- Wear Resistance: Demonstrates excellent wear resistance in frictional environments, ideal for high-wear applications.

- High Temperature Resistance: Has good thermal stability, maintaining its physical properties in high-temperature environments.

- Excellent Processability: Despite the high glass fiber content, the material maintains good flowability, facilitating easy molding and processing.

Applications

- Automotive Components (e.g., Accelerator Pedals): Used in parts like accelerator pedals, offering high strength and durability for automotive applications.

- Mechanical Components: Suitable for heavy-duty mechanical components, ensuring long-term stable operation.

- Enclosure Protection: Can be used for the enclosures of industrial equipment, providing impact resistance and wear protection.

- Gears: Ideal for mechanical gears, capable of withstanding significant working loads while maintaining long service life.

- Bushings: Suitable for bushing components, offering excellent wear resistance and pressure resistance to extend the lifespan.

| Test Properties | Unit | Test Method | Test Condition | Typical Value |

| Physical Properties | ||||

| Density | g/cm³ | ISO 1183 | 1.45 | |

| Filler Content | % | ISO 1172 | GF40 | |

| Mold Shrinkage | % | ISO 294 | Parallel: 0.2%, Vertical: 0.4% | |

| Mechanical Properties | ||||

| Tensile Strength | MPa | ISO 527 | Type I sample, 50mm/min | 205 |

| Elongation at Break | % | ISO 527 | Type I sample, 50mm/min, Gauge length 50mm | 2.6 |

| Flexural Strength | MPa | ISO 178 | 23℃, 10mm/min | 310 |

| Flexural Modulus | MPa | ISO 178 | 23℃, 10mm/min | 11500 |

| Izod Impact Strength (Notched) | KJ/m² | ISO 180 | 23℃ | 13 |

| Charpy Impact Strength (Unnotched) | KJ/m² | ISO 179 | 23℃ | 88 |

| Thermal Properties | ||||

| Melting Point | ℃ | ISO 11357-1 | 260 | |

| Heat Deflection Temperature (HDT) | ℃ | ISO 75 | 0.45MPa: 255℃, 1.8MPa: 250℃ | |

| Flammability | ||||

| UL Flammability Class | UL-94 | HB | ||

| Glow Wire Ignition Temperature (GWIT) | ℃ | IEC 60695-2-13 | - | |

| Electrical Properties | ||||

| Surface Resistivity | Ω | IEC60093 | 100000000000000 | |

| Volume Resistivity | Ω·cm | IEC60093 | 1000000000000000 |

new material

new material