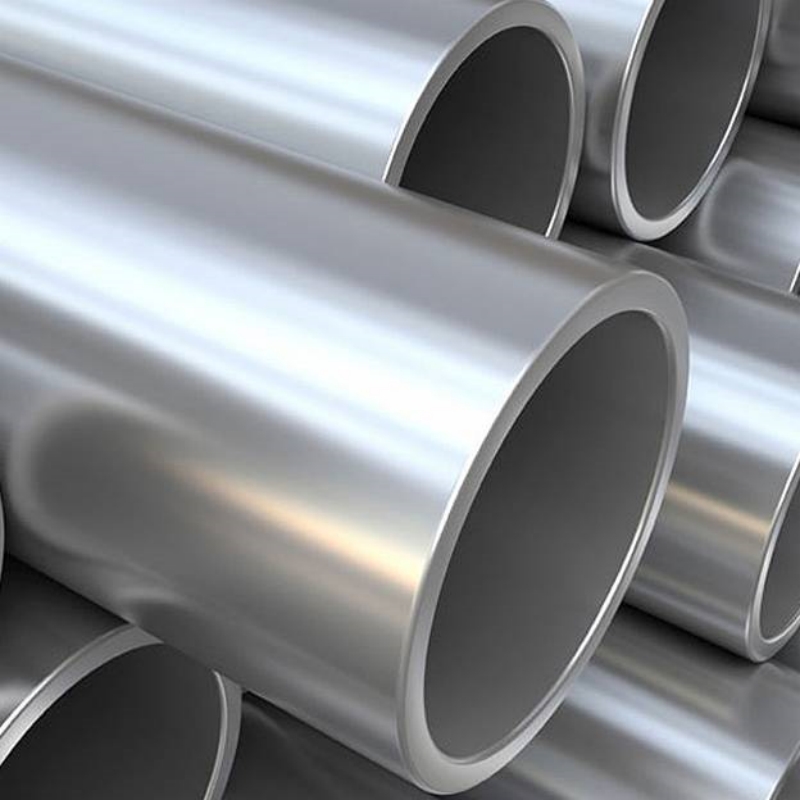

Nickel pipes and tubes are high-purity materials used in various industrial applications, including chemical processing, aerospace engineering, and power generation. They are known for their excellent corrosion resistance, high melting point, and unique properties.

Product Overview:

Nickel Pipe is a high-purity nickel tubular material with a silver-white appearance. It features excellent mechanical strength, ductility, stable chemical properties, and high corrosion resistance, making it suitable for high-temperature and specialized environmental applications.

Features:

- Corrosion Resistance:Exceptional resistance to acidic and alkaline corrosion across diverse environments.

- High-Temperature Stability:Can withstand high temperatures, with a melting point up to 1455°C.

- Excellent Ductility and Malleability:Easy to process and shape, adaptable for various industrial uses.

- Magnetic Properties:Possesses magnetic properties, attracting magnets.

Applications:

- Petrochemical Industry:Used as a catalyst in chemical processes such as hydrogenation and methane synthesis, resistant to poisoning from H₂S and SO₂.

- Aerospace and Defense:Employed in aerospace and defense manufacturing, specifically for nickel-based high-temperature alloys and other structural components.

- Battery Manufacturing:Used as connectors or protective components in the electroplating and battery industries, playing a crucial role in connectivity and protection.

- Electronics and Hardware Manufacturing:Applied in electronic connectors and hardware production, ensuring electrical conductivity and stable connections.

- Advanced Ceramics and Magnetic Materials:Used to produce nickel ferrite and nickel-zinc ferrite for applications such as transformer cores and antennae components.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | <0.001 | ppm | Zn | 0.085 | ppm | Pb | 0.018 | ppm | |||

| B | <0.001 | ppm | Ga | <0.01 | ppm | Bi | <0.005 | ppm | |||

| F | <0.01 | ppm | Ge | <0.05 | ppm | Tl | <0.01 | ppm | |||

| Na | 0.03 | ppm | As | <0.01 | ppm | U | <0.001 | ppm | |||

| Mg | 0.013 | ppm | Se | 0.03 | ppm | Br | <0.01 | ppm | |||

| Al | 0.01 | ppm | Zr | <0.005 | ppm | Ru | 0.015 | ppm | |||

| Si | 0.04 | ppm | Nb | <0.01 | ppm | Rh | 0.025 | ppm | |||

| P | 0.0055 | ppm | Mo | <0.01 | ppm | Os | 0.2 | ppm | |||

| Cl | <0.05 | ppm | Pd | <0.05 | ppm | Cd | 0.015 | ppm | |||

| K | <0.05 | ppm | Ag | 0.08 | ppm | In | <0.005 | ppm | |||

| Ca | <0.05 | ppm | Sn | <0.01 | ppm | ||||||

| Ti | 0.18 | ppm | Sb | 0.13 | ppm | ||||||

| V | <0.001 | ppm | Ba | <0.001 | ppm | ||||||

| Cr | 0.025 | ppm | Hf | <0.005 | ppm | ||||||

| Mn | 0.003 | ppm | Ta | <1 | ppm | C | 2.9 | ppm | |||

| Fe | 3.4 | ppm | W | <0.01 | ppm | S | <1 | ppm | |||

| Co | 0.72 | ppm | Pt | <0.05 | ppm | O | 18 | ppm | |||

| Ni | Matrix | wt% | Au | <0.05 | ppm | N | 3.5 | ppm | |||

| Cu | 0.085 | ppm | Hg | <0.05 | ppm | H | <1 | ppm |

new material

new material