Mordenite molecular sieve is a high-performance zeolite material designed for selective adsorption and catalytic applications in industrial processes. Featuring a well-defined microporous structure, it provides excellent thermal stability, controlled acidity, and superior ion-exchange capacity, making it highly effective for hydrocarbon conversion, gas separation, and petrochemical refining. This molecular sieve is widely used in dehydration, selective catalysis, and large-scale industrial purification processes, ensuring reliable performance for continuous operations.

Product Overview

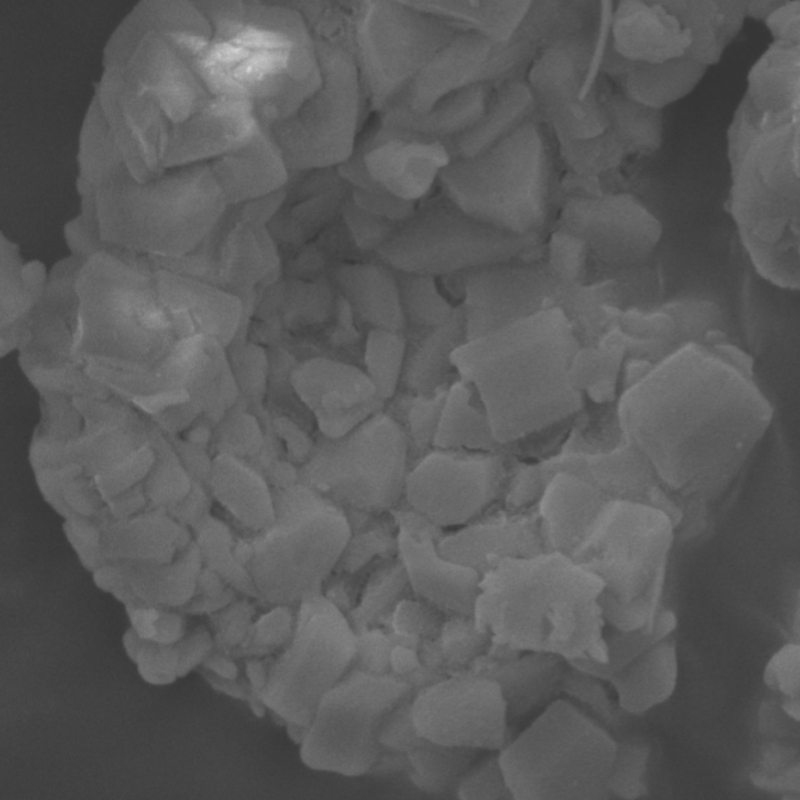

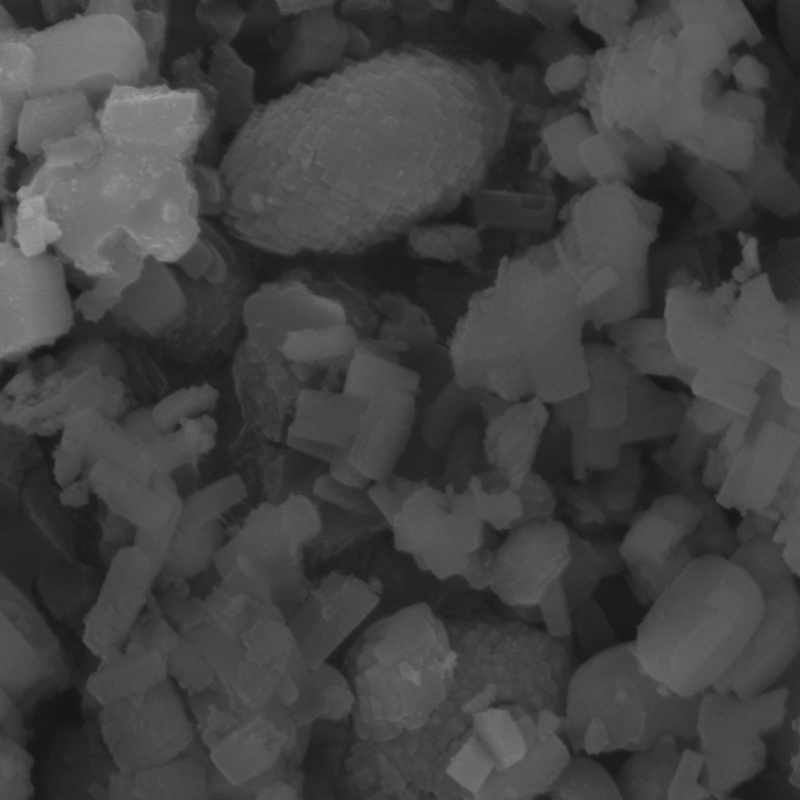

Mordenite molecular sieve is a silica-alumina zeolite featuring a unique two-dimensional pore system primarily composed of twelve-membered rings. The crystal structure includes four-membered, six-membered, and eight-membered rings, with a significant number of five-membered rings that are connected through oxygen bridges, forming a more complex pore network. Due to its high silica/alumina ratio and distinctive five-membered ring structure, Mordenite exhibits excellent acid resistance and thermal stability, making it widely used in hydrocarbon conversion and adsorption processes.

Key Features

- High Silica/Alumina Ratio: Ensures excellent catalytic performance and thermal stability, making it suitable for high-temperature and acidic environments.

- Complex Pore Structure: The two-dimensional pore system, including interconnected main and small channels, provides efficient molecular sieving capabilities.

- Superior Acid and Heat Resistance: The high silica/alumina ratio and five-membered ring structure grant Mordenite strong acid resistance and thermal stability, ideal for applications in high-temperature and acidic conditions.

- Unique Pore Channels: The twelve-membered ring pore structure offers an optimal pore size for effective molecular separation, particularly for hydrocarbon molecules.

Applications

- Catalytic Reactions: As an active component and carrier for hydrocarbon conversion, Mordenite is widely used in catalytic processes such as C5/C6 isomerization, toluene disproportionation, pseudocumene isomerization, and tetramethylbenzene isomerization.

- Adsorption and Drying: Used as a desiccant and adsorbent, especially in molecular sieve separation and gas purification applications.

- Petrochemical Industry: Applied in petroleum cracking and other refining processes to enhance catalytic efficiency and improve product quality.

| Item | Data |

| Appearance (Shape) | White Powder |

| Cation Type | Na, H |

| SiO₂/Al₂O₃ Ratio (mol/mol) | 20~25 |

| Crystallinity (%) | ≥90 |

| Surface Area (BET) (m²/g) | ≥250 |

| Na₂O (m/m %) | ≤0.1 |

| Loss on Ignition (LOI) (m/m %) | ≤10 |

new material

new material