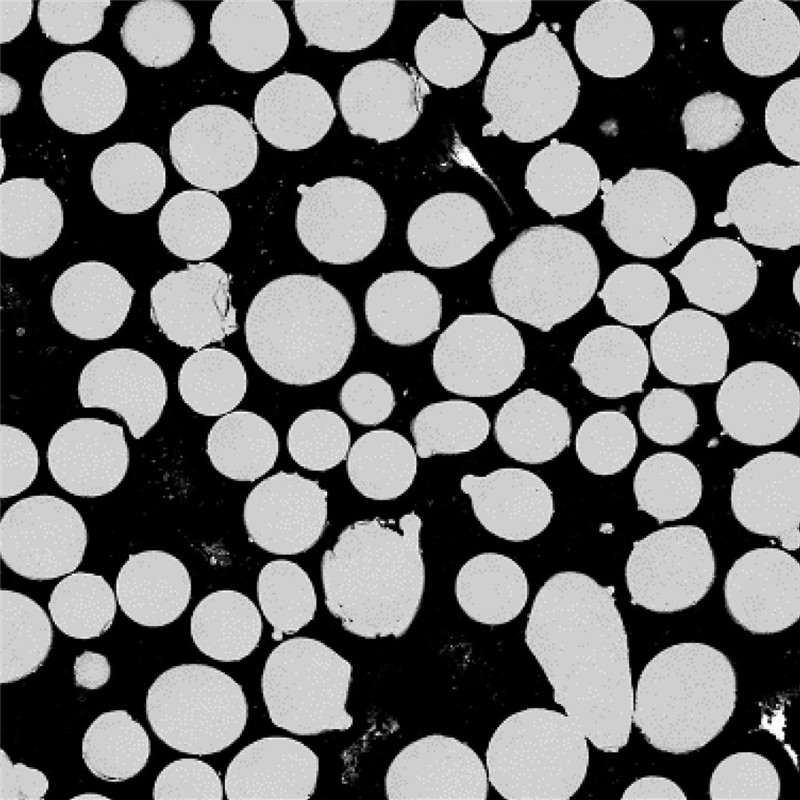

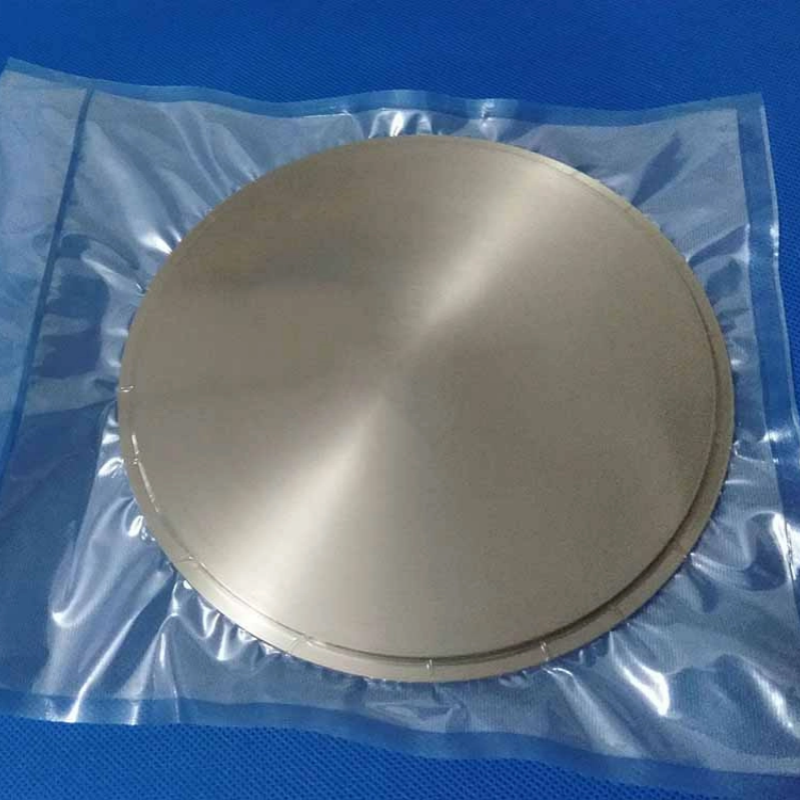

K477 High-Temperature Alloy Powder is a nickel-based superalloy powder specially developed for aerospace, power generation, and high-temperature industrial applications. It is known for its exceptional heat resistance, oxidation and corrosion resistance, and outstanding mechanical properties. This powder is highly suitable for additive manufacturing and advanced engineering processes, enabling the production of durable, high-performance components for extreme environments.

Product Overview

K477 High-Temperature Alloy Powder is an alloy powder composed of nickel, chromium, and cobalt, specifically designed for high-temperature and corrosion-resistant environments. It exhibits excellent mechanical properties and oxidation resistance, making it ideal for key components in extreme working conditions. This alloy provides exceptional high-temperature stability and long-term performance.

Product Features

- High-Temperature Stability:Designed to withstand extreme high temperatures while maintaining excellent structural stability and strength.

- Corrosion Resistance:Outstanding oxidation and corrosion resistance under high-temperature conditions, ensuring long-term stability.

- Excellent Mechanical Properties:Maintains high strength and toughness at high temperatures, capable of withstanding high-load conditions.

- Machinability:Suitable for modern manufacturing processes, including 3D printing and powder metallurgy.

Applications

- Aerospace:Used in the manufacture of aircraft engines, gas turbines, and other high-temperature components.

- Energy Industry:Suitable for gas turbines, heat exchangers, and other high-temperature equipment components.

- Chemical Equipment:Applied in the production of high-temperature and corrosion-resistant chemical reactors, pipelines, and related equipment.

- Metallurgical Industry:Provides exceptional wear resistance and strength for use in smelting and high-temperature environments.

new material

new material