High-purity calcium carbonate (20-110nm) offers optimized particle uniformity, superior chemical stability, and enhanced dispersion. Designed for coatings, plastics, and biomedical applications, it ensures improved mechanical reinforcement, extended durability, and high adaptability.

Product Overview

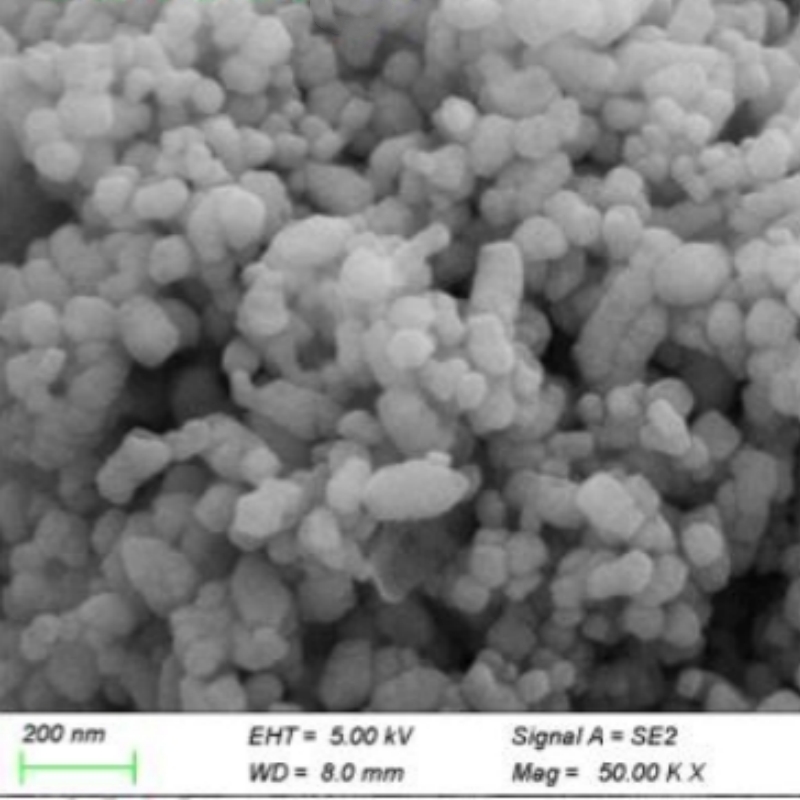

High-quality high-purity calcium carbonate is a new type of lightweight nano-calcium carbonate product that exhibits excellent characteristics such as small particle size, uniform distribution, large specific surface area, and high surface activity. These features give it performance advantages that regular calcium carbonate does not possess in practical applications. Nano-calcium carbonate usually exists in the form of calcite and is widely used in various fields, especially in polymers and adhesives that require modification and performance enhancement. Surface modification treatments can improve its dispersion, allowing it to function well in a variety of materials.

Key Features

- Low Water Content & Chemical Stability:It offers excellent chemical stability and does not react with curing agents or adhesives, making it suitable for use in various adhesives.

- Cost Reduction:High filler content allows for a significant reduction in the cost of adhesive products, with wide applications in silicone rubber seals and polyurethane adhesives.

- Reinforcement & Performance Optimization:Enhances the mechanical properties of adhesives, reduces curing shrinkage and thermal expansion coefficient, increases thermal conductivity, and boosts heat resistance, adhesion, and mechanical strength.

- Thixotropy Adjustment:Well compatible with adhesives, it can act as a thixotropic agent, adjusting the viscosity of adhesives and improving their thixotropic properties.

- Coloring Performance:When used in pigments, nano-calcium carbonate is easily colored without affecting the color of the final product.

- Versatile Modifying Effects:It offers various functions in different adhesives, such as improving the rheological performance of PVC plastics, increasing the strength and wear resistance of silicone sealants, and enhancing the heat resistance of hot melt adhesives.

Applications

- Plastic Industry:As a filler and reinforcement agent, nano-calcium carbonate enhances the rigidity, toughness, and heat resistance of plastic products, improving processing performance.

- Rubber Industry:Used in high-performance tires, automotive parts, and other products, it increases strength, rigidity, and durability.

- Paper Industry:Acts as a filler, improving the brightness, whiteness, and smoothness of paper, especially for high-grade packaging papers.

- Coatings & Inks:In coatings and inks, nano-calcium carbonate enhances gloss and durability while reducing production costs.

- Pharmaceutical Industry:Used as a component in culture media and a calcium source additive, applicable in the production of antibiotics, painkillers, and antacid products.

| Parameter | Value |

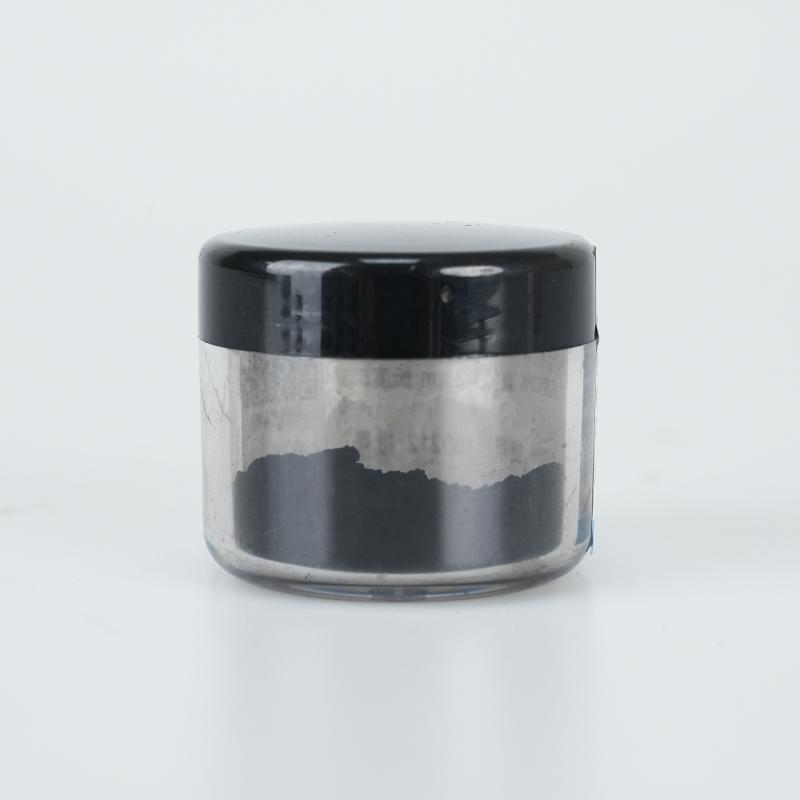

| Morphology | White powder |

| Particle Size | 20-110 nm |

| Purity | >99% |

| Moisture Content | ~0.28% |

| Whiteness | ~95.2 |

| pH Value | ~9.55 |

| Specific Surface Area | ~24 m²/g |

| Loss on Ignition | ~43.6% |

| Magnesium Oxide Content | ~0.26% |

new material

new material