Product Overview

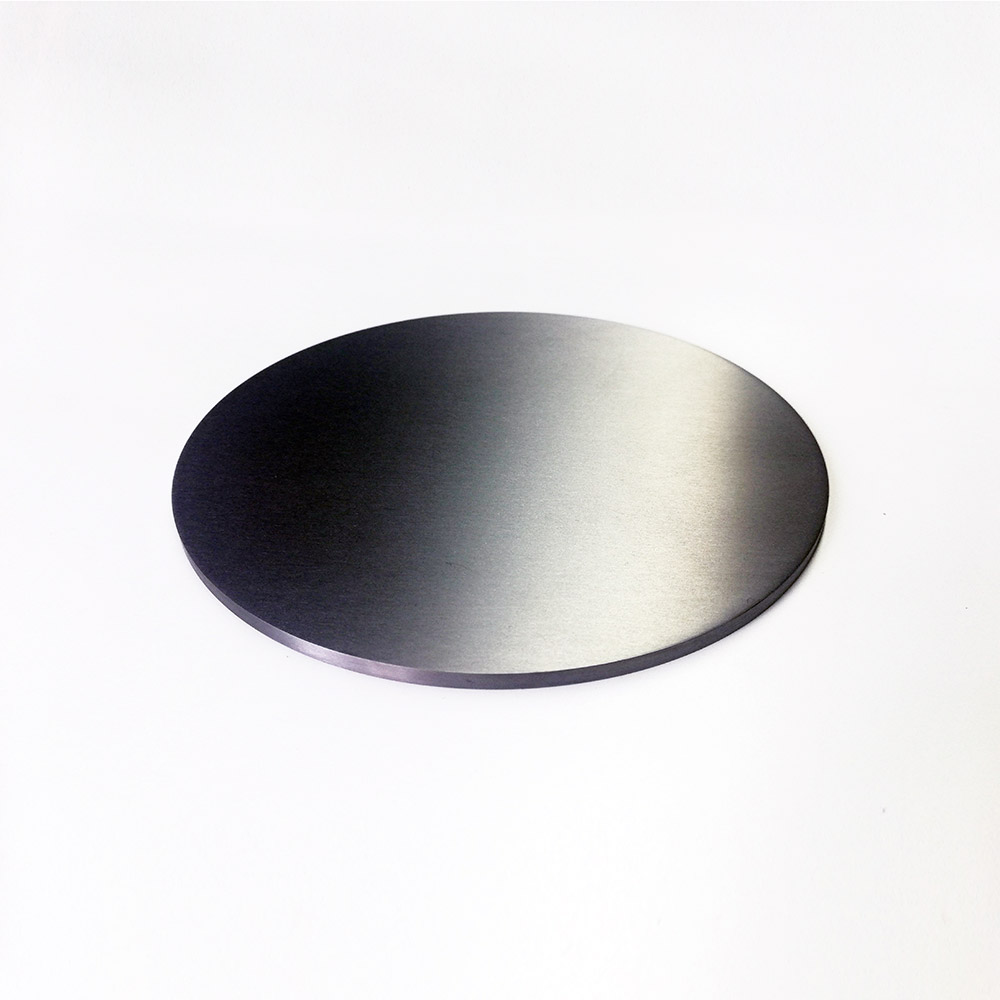

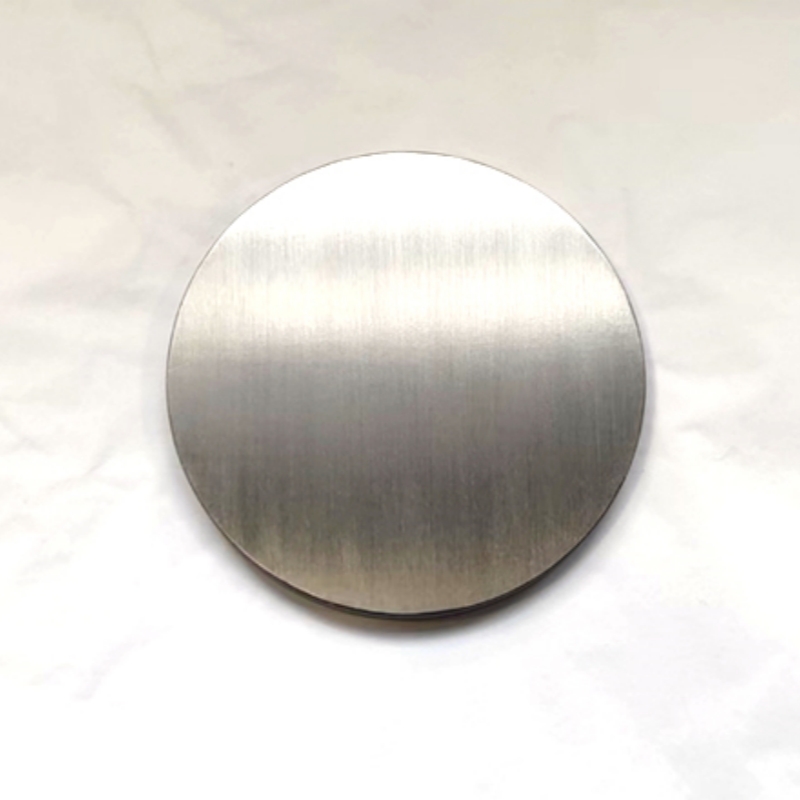

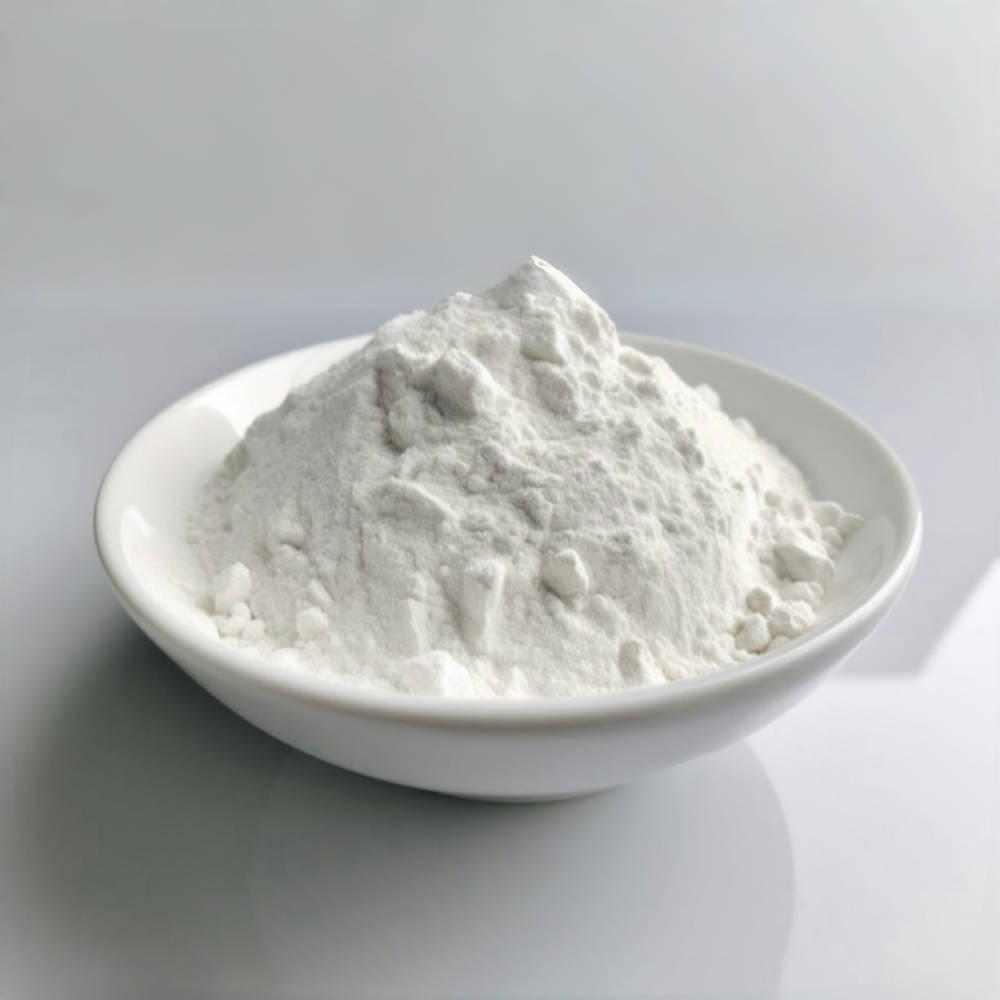

High purity tantalum targets are produced from high-purity tantalum powder through processes like sintering, electron beam melting, repeated plastic deformation, and annealing. These targets offer exceptional thermal stability and excellent electrical conductivity. Tantalum targets are widely used in the electronics, semiconductor, and optics industries, particularly in magnetron sputtering and thin-film deposition applications. With their high density and excellent high-temperature properties, they are particularly favored in high-end applications, including capacitors, engine turbine blades, and chemical processing equipment.

Features

- Excellent Electrical Conductivity and Thermal Stability: Tantalum targets have outstanding electrical conductivity and resistance to high temperatures, making them suitable for use in extreme conditions.

- High Density and Ductility: The high density of tantalum ensures excellent mechanical properties, and it maintains stability under high-temperature conditions.

- Versatile Shapes: Available in flat, rotating, and custom shapes to meet specific application needs.

- Precision Manufacturing: Advanced electron beam melting technology ensures the high purity and uniformity of the target material.

Applications

High purity tantalum targets are extensively used in the following industries:

- Electronics: Tantalum targets are widely used in capacitor production, especially in high-end applications such as telecommunications, data storage, and medical devices.

- Semiconductor Industry: Used in Physical Vapor Deposition (PVD) processes to deposit thin films on semiconductor substrates, forming diffusion barriers for copper interconnects.

- Aerospace: In aerospace applications, tantalum targets are used for producing high-temperature alloys, such as those used in turbine blades, due to their excellent heat resistance and corrosion resistance.

- Chemical Processing: Tantalum’s corrosion resistance makes it an ideal material for equipment in the chemical and pharmaceutical industries, often used in manufacturing containers, pipes, valves, and heat exchanger linings.

- Optics and Thin Film Technology: Tantalum targets are commonly used in optical coating, flat-panel displays, and functional material thin films.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | ppm | Zn | ppm | Pb | ppm | ||||||

| B | ppm | Ga | ppm | Bi | ppm | ||||||

| F | ppm | Ge | ppm | Y | ppm | ||||||

| Na | ppm | As | ppm | Th | ppm | ||||||

| Mg | ppm | Se | ppm | Er | ppm | ||||||

| Al | ppm | Zr | <10 | ppm | Ru | ppm | |||||

| Si | <10 | ppm | Nb | <150 | ppm | Rh | ppm | ||||

| P | ppm | Mo | <10 | ppm | Os | ppm | |||||

| Cl | ppm | Pd | ppm | Cs | ppm | ||||||

| K | ppm | Ag | ppm | ||||||||

| Ca | ppm | Sn | ppm | ||||||||

| Ti | <10 | ppm | Sb | ppm | |||||||

| V | ppm | Ba | ppm | ||||||||

| Cr | <10 | ppm | Hf | ppm | |||||||

| Mn | <10 | ppm | Ta | Matrix | wt% | C | <10 | ppm | |||

| Fe | <10 | ppm | W | <100 | ppm | S | <10 | ppm | |||

| Co | ppm | Pt | ppm | O | <20 | ppm | |||||

| Ni | <10 | ppm | Au | ppm | N | <5 | ppm | ||||

| Cu | <10 | ppm | Hg | ppm | H | <5 | ppm |

new material

new material