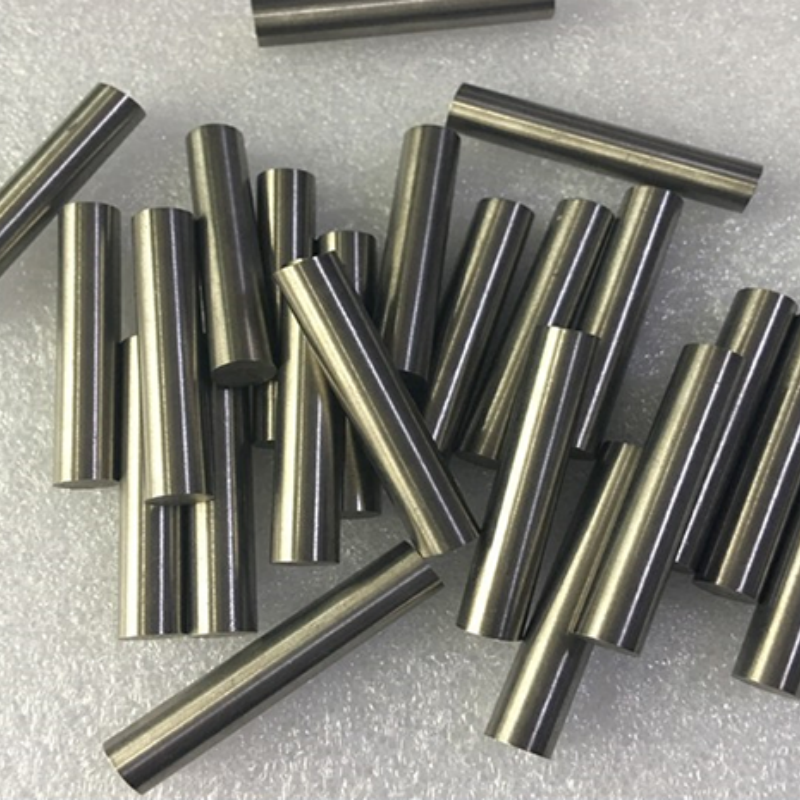

Product Overview

High purity niobium rods are metal materials known for their exceptional corrosion resistance, high-temperature stability, and good ductility. Niobium, a gray-white metal with high melting and boiling points, remains stable in high-temperature and harsh environments. These rods are widely used in industries where high durability and resistance to corrosion are required, particularly in environments exposed to high temperatures, radiation, and chemical corrosion.

Features

- High Purity:Ensures material stability and superior performance.

- Strong Corrosion and Oxidation Resistance:Performs excellently in harsh environments.

- Good Mechanical Properties and Ductility:Suitable for various processing methods.

- High Temperature and Chemical Resistance:Ideal for high-temperature applications and corrosive environments.

- Outstanding Electrical and Thermal Performance:Reliable in both electrical and heat-related applications.

Applications

- Nuclear Industry:Niobium rods are used in nuclear reactors and nuclear fuel cladding due to their low thermal neutron absorption.

- Superconducting Technology:Niobium is a critical material in superconducting applications.

- Aerospace:Ideal for high-temperature alloys and aerospace structures.

- Steel and Alloy Manufacturing:Used as an alloy element to improve material strength, toughness, and heat resistance.

- Electrical Ceramics and Medical Applications:Applied in electrical ceramics and medical devices where high stability is required.

- Chemical Industry:Used in chemical reactors and equipment for their excellent corrosion resistance, especially under high temperatures.

- Arc Welding:Niobium rods are used for arc welding and special metal welding, especially in stabilizing stainless steel.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | Se | Er | |||||||||

| Al | Zr | <10 | ppm | Ru | |||||||

| Si | <5 | ppm | Nb | Matrix | wt% | Rh | |||||

| P | Mo | <10 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | <5 | ppm | Sb | ||||||||

| V | Ba | ||||||||||

| Cr | <10 | ppm | Hf | ||||||||

| Mn | Ta | 42 | ppm | C | 29 | ppm | |||||

| Fe | 10 | ppm | W | 20 | ppm | S | |||||

| Co | Pt | O | 100 | ppm | |||||||

| Ni | <10 | ppm | Au | N | 10 | ppm | |||||

| Cu | Hg | H | 10 | ppm |

new material

new material