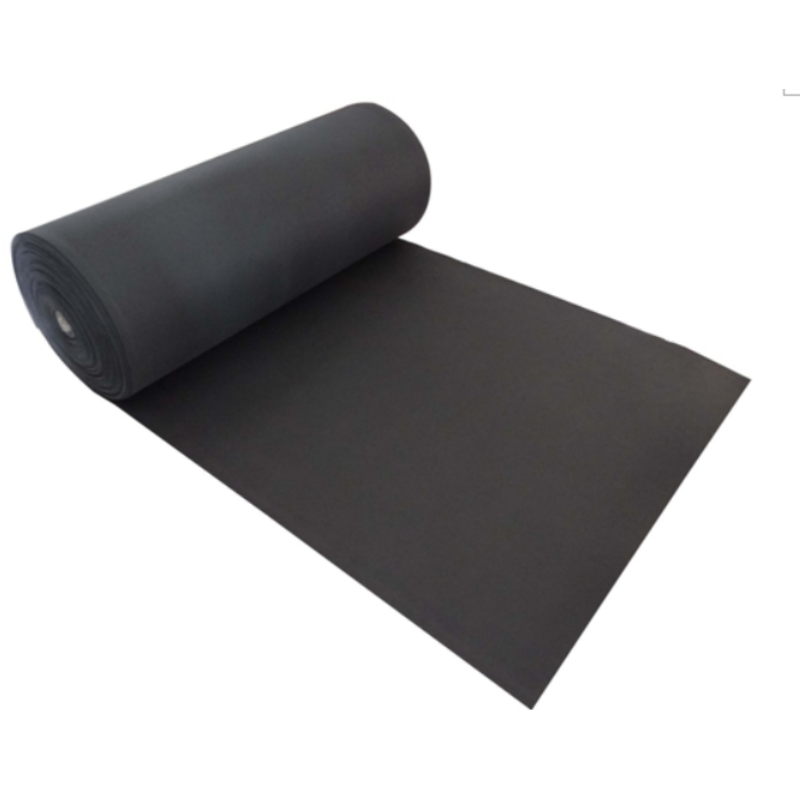

Flow battery electrode felt is a high-performance carbon-based material engineered for applications requiring optimized electrochemical activity, superior conductivity, and extended durability. Manufactured through advanced carbonization and fiber processing techniques, this felt delivers excellent electrolyte permeability, stable structural integrity, and reliable energy transfer efficiency. It is widely used in vanadium redox flow batteries, energy storage systems, fuel cells, and industrial electrochemical applications, ensuring long-term performance in demanding environments.

Product Overview

Flow battery electrode felt is a porous material processed through a series of techniques, including non-woven needle punching, pre-oxidation, carbonization, graphitization, and micro-activation. It is primarily used as the electrode material in flow batteries. This material boasts excellent electrochemical stability, high porosity, and a large surface area, which significantly enhances the electrode reaction rate and charge transfer capability. The electrode felt is not only highly corrosion-resistant but also exhibits excellent adsorption properties, effectively adsorbing and storing active substances from the electrolyte. This improves the energy density and cycling stability of flow batteries. It is widely applied in Vanadium Redox Flow Batteries (VRFB), Zinc-Bromine Flow Batteries, and Zinc-Air Flow Batteries.

Key Features

- High Electrode Reaction Rate: Enhances energy conversion efficiency of the battery.

- High Charge Transfer Capability: Effectively improves battery performance.

- Corrosion Resistance: Stable and durable for long-term use in various environments.

- Good Adsorption Performance: Improves storage capacity for active substances in the electrolyte.

Applications

- Vanadium Redox Flow Batteries (VRFB): Used in large-scale energy storage systems, boosting battery efficiency.

- Zinc-Bromine Flow Batteries: Serves as an efficient electrode material to optimize battery performance.

- Zinc-Air Flow Batteries: Applied in energy storage to enhance cycling stability and overall performance.

| Indicator Name | Unit | Value |

| Carbon Content | wt% | >99 |

| Bulk Density | g/cm³ | 0.08-0.11 |

| Specific Surface Area | m²/g | 2.3-4 |

| Felt Shedding Rate | g/100g | 2~3 |

| Surface Resistance | Ω/cm² | <0.15 |

| Ash Content | ppm | <300 |

| Thickness | mm | 2-5 ± 7.5% |

| Width | m | 1.35/1.45 ± 0.05 |

| Length | m | 10-100 ± 0.5 |

new material

new material