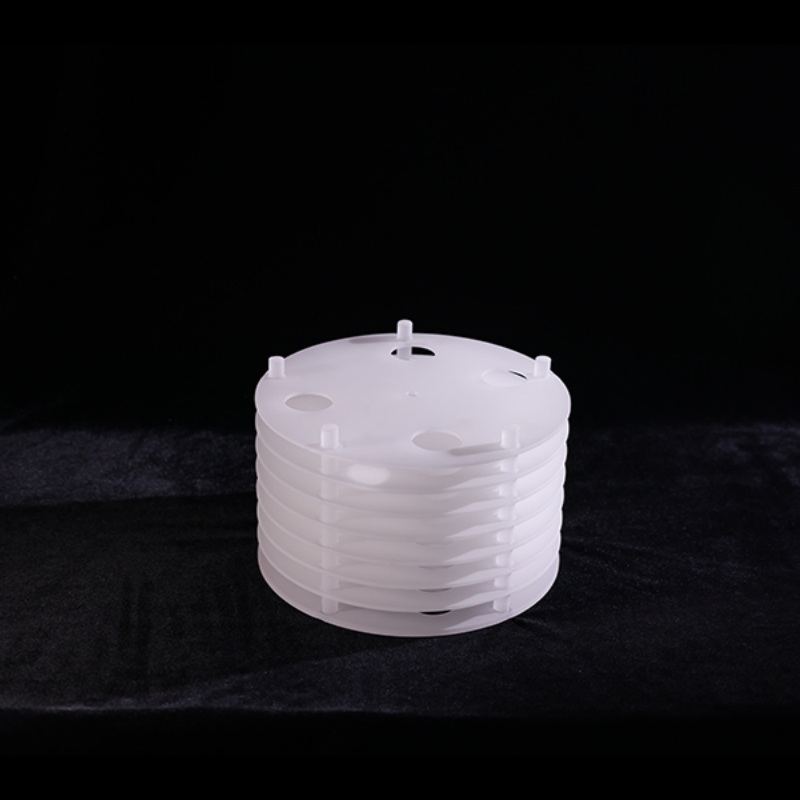

Finned insulation barrel is a high-performance thermal-resistant component designed for superior heat dissipation, structural durability, and optimized insulation. Engineered with integrated fins for enhanced thermal efficiency, it offers excellent resistance to high temperatures, minimal thermal expansion, and strong mechanical stability. This specialized material is widely used in semiconductor processing, aerospace applications, high-temperature furnaces, and industrial thermal management systems, ensuring efficient heat regulation and durability in demanding environments.

Product Overview

The finned insulation barrel is an efficient thermal insulation device combining high-purity quartz and metal materials. It features a specially designed fin structure to enhance heat conduction efficiency, effectively isolating the barrel's interior from external thermal exchange and maintaining a stable internal temperature. This product is widely used in the semiconductor industry to provide temperature control and insulation, particularly in processes requiring precise thermal management such as Chemical Vapor Deposition (CVD), annealing, and other temperature-sensitive operations.

Key Features

- High Purity Materials: Made from high-purity quartz and metal materials, ensuring excellent insulation and high-temperature resistance.

- Finned Design: The fin structure enhances heat conduction and dissipation, ensuring more even heating and temperature control.

- High-Temperature Resistance: Can withstand extremely high temperatures, making it suitable for high-temperature applications in semiconductor manufacturing.

- Good Insulation Properties: Effectively reduces heat loss and maintains stable internal temperatures.

- Stable Structure: The well-designed structure ensures durability and resistance to long-term wear and tear, making it ideal for extended use.

Applications

- Semiconductor Industry: Used in heating and temperature control equipment during semiconductor production to ensure high-precision temperature management.

- Optical Manufacturing: Provides precise temperature control for the processing and heat treatment of optical components.

- Heat Treatment Processes: Applied in various heat treatment equipment to ensure temperature stability and uniformity.

- Laboratory Equipment: Serves as high-temperature insulation equipment in laboratories for material processing and analysis.

new material

new material