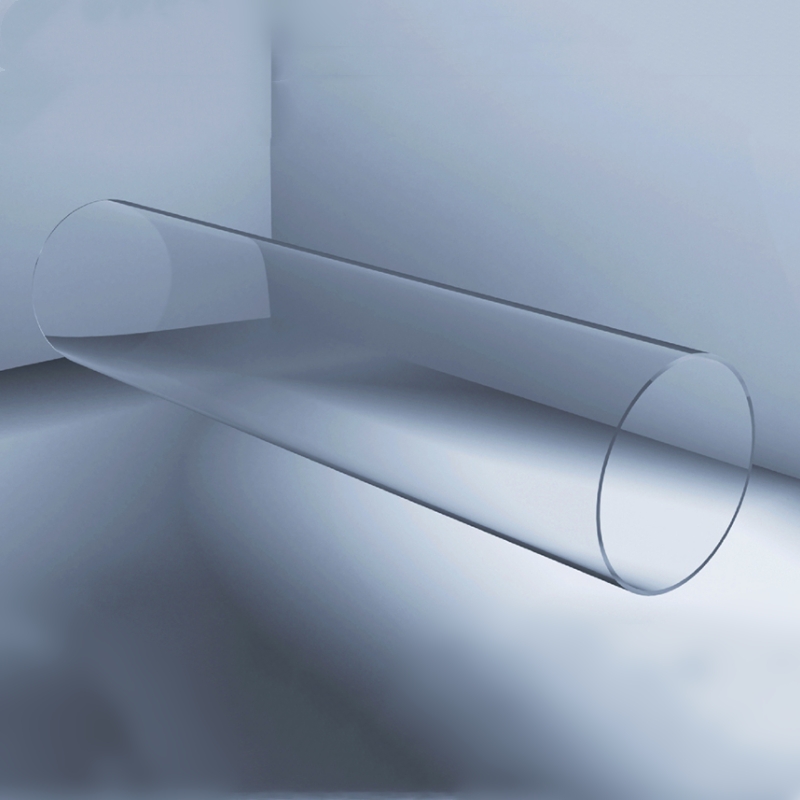

Electric fused quartz is a high-purity silica material manufactured through an advanced electric fusion process, ensuring superior thermal stability, minimal thermal expansion, and excellent optical transparency. Engineered for demanding applications, it offers exceptional chemical resistance, mechanical durability, and high-temperature performance. This versatile material is widely used in semiconductor processing, precision optics, aerospace components, and scientific research, providing reliable stability and clarity in extreme environmental conditions.

Product Overview

Electric Fused Quartz is a high-performance material with low hydroxyl content, high purity, and exceptional high-temperature resistance. It is widely used in high-temperature environments and precision optical applications. With excellent thermal stability and mechanical strength, electric fused quartz maintains stable performance under extreme conditions. It is extensively used in the semiconductor industry as a critical component in diffusion furnaces and chemical vapor deposition (CVD) furnaces, and is suitable for applications requiring high temperature and high purity.

Key Features

- Low Hydroxyl Content: The low hydroxyl content reduces impurity introduction, enhancing its purity and stability.

- High Purity: Its superior purity provides outstanding optical and mechanical performance under high-temperature conditions.

- Strong High-Temperature Resistance: Can withstand extremely high temperatures, making it ideal for applications in demanding thermal environments.

- Excellent Thermal Stability: High thermal stability allows it to operate stably under extreme temperature variations and high heat conditions.

Applications

- Semiconductor Industry: Used as a core component in diffusion furnaces, CVD furnaces, and other semiconductor equipment, meeting high purity and high-temperature requirements.

- Optical Industry: Applied in high-temperature optical devices, offering excellent thermal stability and transparency.

- Electronics Industry: Used in the electronics manufacturing process where high-purity materials are required.

- High-Temperature Processing: Suitable for other high-temperature environments such as material heat treatment and precision processing equipment.

new material

new material