Silicon carbide nanopowder provides optimized hardness, superior thermal stability, and enhanced electrical conductivity. Designed for high-performance ceramics and semiconductor applications, it ensures improved wear resistance, extended durability, and high adaptability.

Product Overview

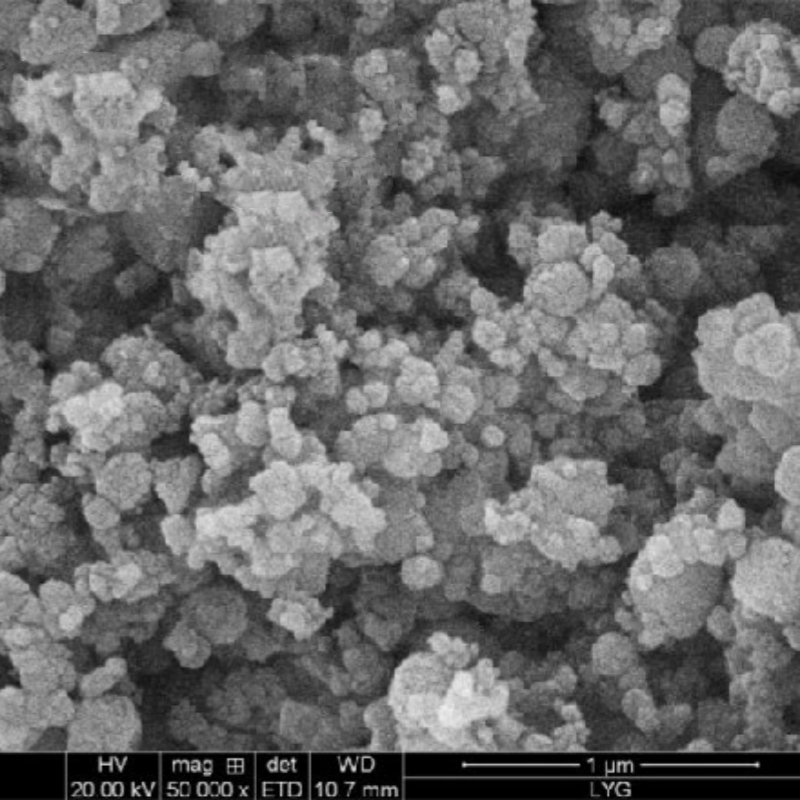

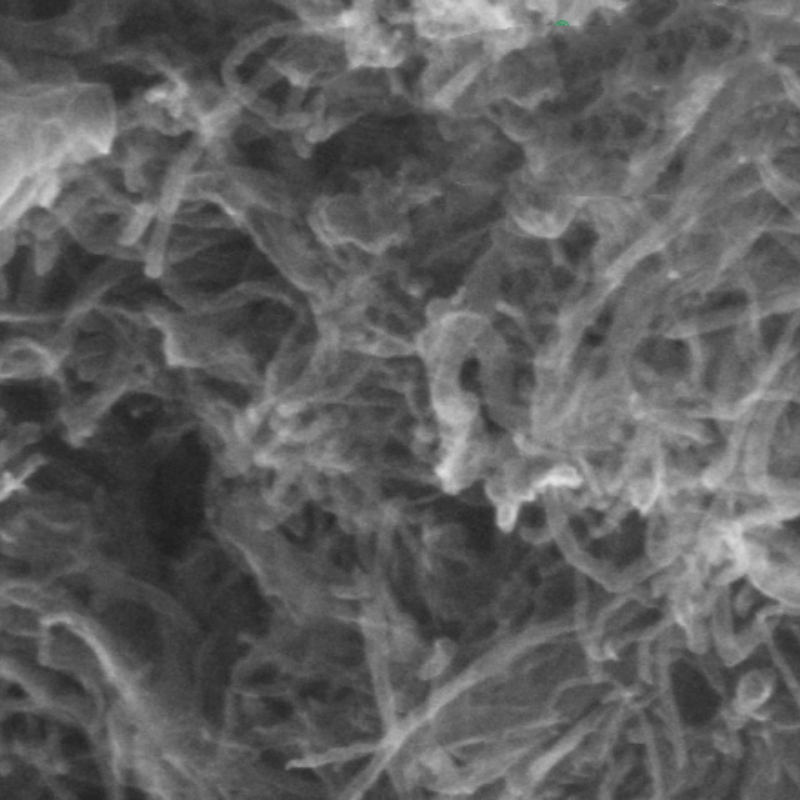

Silicon carbide (SiC) is a binary compound semiconductor composed of silicon and carbon atoms. It exhibits exceptional hardness, high thermal stability, and excellent thermal conductivity. With a crystalline structure known for its remarkable chemical stability and mechanical strength, SiC is ideal for use in high-temperature, high-strength, and high-wear environments. Silicon carbide nanopowder finds widespread application in coatings, abrasive materials, specialty ceramics, supercapacitors, and more.

Key Features

- High Thermal Conductivity: Silicon carbide nanopowder has outstanding thermal conductivity, performing excellently in high-temperature environments.

- Low Thermal Expansion Coefficient: Its low thermal expansion coefficient helps reduce stress and deformation caused by temperature changes.

- High Mechanical Strength: SiC provides high strength and hardness, falling between corundum (Al₂O₃) and diamond.

- Chemical Stability: Excellent corrosion resistance and antioxidant properties, maintaining stability even in harsh environments.

- Wear Resistance: Exceptional wear resistance, making it suitable for durable, long-lasting materials.

Applications

- Coatings and Paints: Used to enhance the wear resistance and durability of coatings and paints.

- Automotive, Chemical, and Oil Drilling Industries: Due to its high thermal conductivity and low thermal expansion, it is extensively used in these industries.

- Radar and High-Temperature Radiation Environments: SiC is applied in environments requiring superior thermal properties and chemical stability.

- High-Performance Refractory Materials and Specialty Ceramics: Increases the heat resistance and wear performance of materials.

- Abrasive and Reinforcement Materials: Used for grinding and enhancing materials to improve their performance.

- Optical Spectrum: Applied in the manufacture of high-performance optical devices and high-temperature spectroscopic equipment.

- Supercapacitor Electrode Materials: As an electrode material, SiC nanopowder offers excellent stability and conductivity, widely used in supercapacitors.

| Parameter | Description |

| Diameter | ~50 nm |

| Appearance | Gray powder |

| Purity | >99 at% |

new material

new material