Benzene oxidation to phthalic anhydride catalyst is a high-performance catalytic material designed for the selective oxidation of benzene to phthalic anhydride with superior efficiency and stability. Engineered with optimized metal-supported formulations, it enhances reaction kinetics, improves oxidation selectivity, and ensures prolonged operational lifespan for industrial applications. This catalyst is widely used in fine chemical production, plasticizer synthesis, and pharmaceutical intermediate manufacturing, delivering reliable performance for continuous catalytic oxidation.

Product Overview

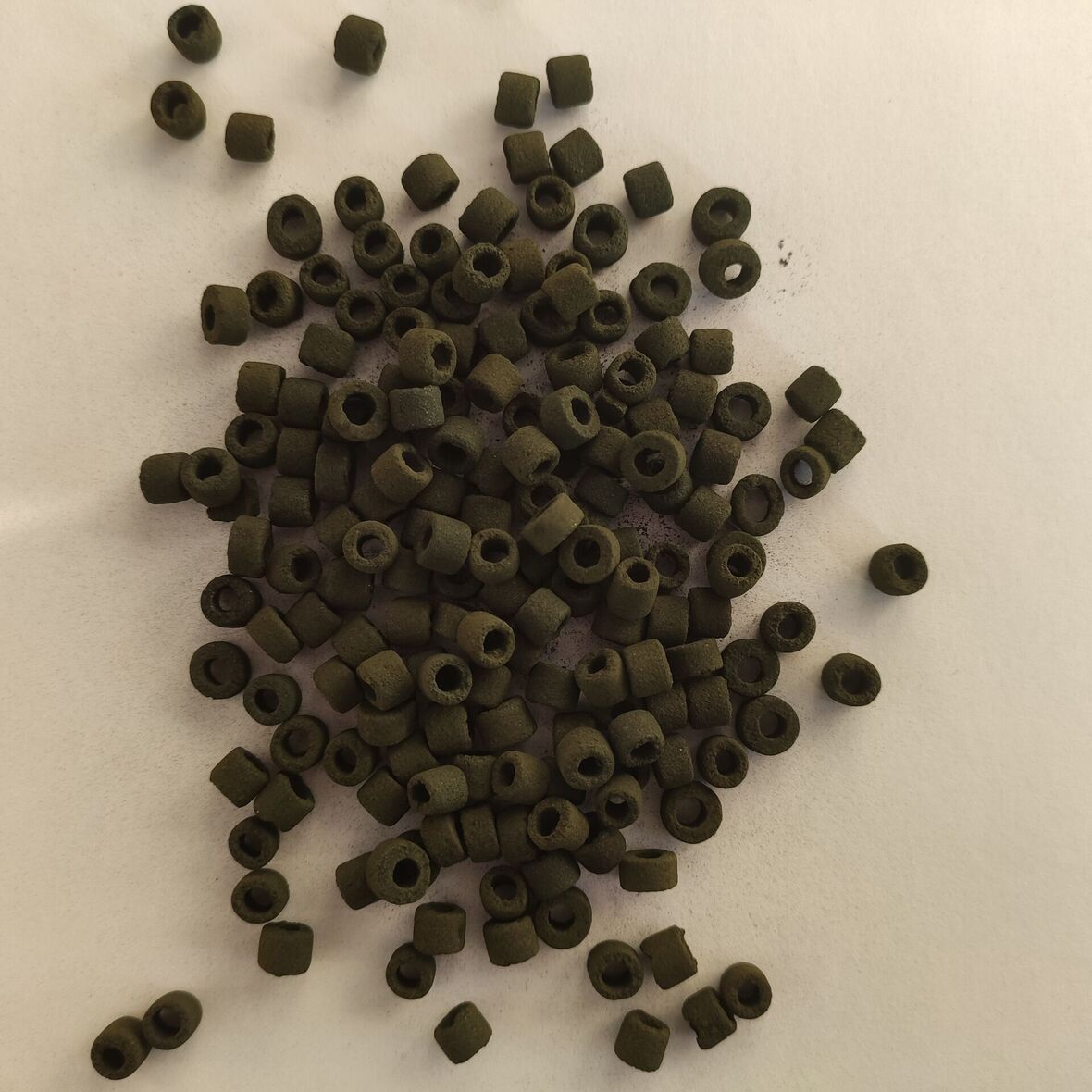

The Benzene Oxidation to Phthalic Anhydride Catalyst is specifically designed for the benzene oxidation process to produce phthalic anhydride. It uses V₂O₅ and MoO₃ as the main active components, supported on an inert carrier, providing high activity and stability. The catalyst is used in fixed-bed reactors to efficiently catalyze the benzene oxidation reaction, achieving a conversion rate of 98%-99%, with phthalic anhydride yield as high as 90%-95%. After pre-activation and longevity treatments, the catalyst significantly shortens the startup induction period, and its service life can reach over 2 years.

Key Features

- High Activity & High Conversion Rate: Conversion rate of 98%-99%, with phthalic anhydride yield up to 90%-95%, ensuring high production efficiency.

- Excellent Selectivity: The catalyst exhibits excellent selectivity in the benzene oxidation reaction, maximizing the yield of phthalic anhydride.

- High Strength & Long Service Life: The catalyst has high strength and stability, with a service life of over 2 years, reducing production costs.

- Reduced Startup Time: Pre-activation and longevity treatments significantly reduce the startup induction period, improving production efficiency and startup time.

Applications

- Benzene Oxidation to Phthalic Anhydride: Widely used in the industrial production of phthalic anhydride, enhancing production efficiency and product quality.

- Chemical Production: Used in the production of phthalic anhydride and its derivatives, which are important chemical raw materials.

- Petrochemical Industry: In the petrochemical industry, the catalyst is used for the oxidation of aromatics, producing high-value-added chemical products.

| Item | Specification | Unit |

| Temperature | Initial 430-460℃, Normal 400-430℃ | ℃ |

| Space Velocity | 2000-2500 hr⁻¹ | hr⁻¹ |

| Benzene Concentration | 42g-48g/m³ (optimal, also usable at 52g/m³) | g/m³ |

| Activity Level | Benzene Conversion Rate 98%-99% | % |

new material

new material