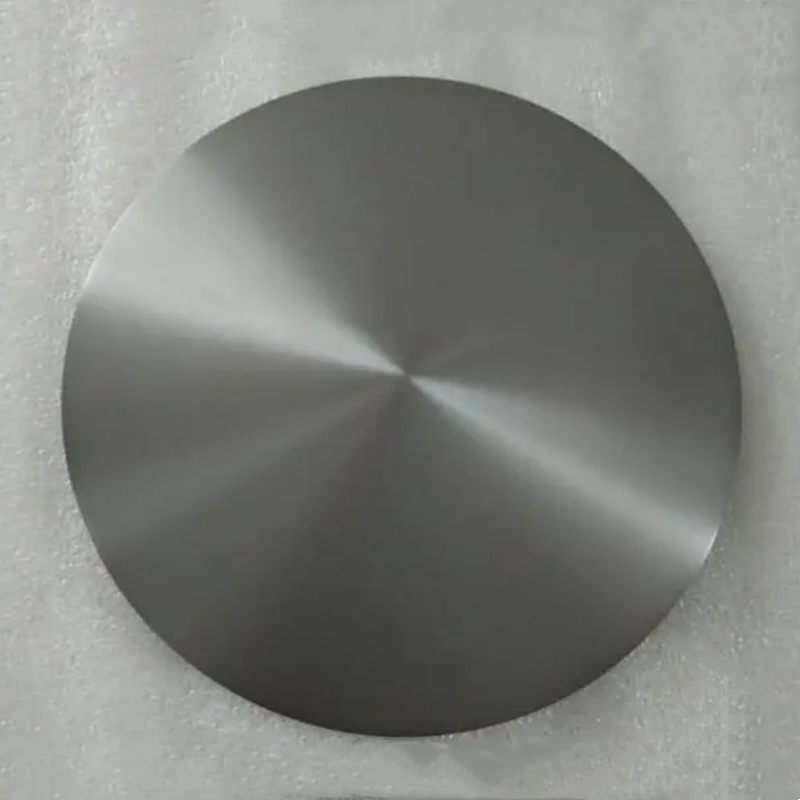

Product Overview

Titanium sputtering target is a high-purity material with a silver-white luster, offering excellent corrosion resistance and high strength. Titanium has a melting point of 1660°C and a density of 4.5g/cm³, along with good biocompatibility, making it widely used in the biomedical field. Titanium targets are typically used in vacuum evaporation deposition processes, applied in wear-resistant coatings, decorative coatings, semiconductors, and optical coatings.

Key Features

· High Purity: Available in 4N and 4N5 purity, ensuring excellent performance and stability.

· Excellent Corrosion Resistance: Titanium’s exceptional corrosion resistance allows it to maintain excellent performance in a wide range of harsh environments.

· High Strength and Lightweight: Titanium’s combination of strength and light weight makes it ideal for aerospace, medical, and decorative applications.

· Biocompatibility: Due to its biocompatibility, titanium is widely used in medical devices and implants.

· Variety of Shapes: Titanium sputtering targets are available in flat, rotary, and custom-shaped forms to suit different application requirements.

Applications

Titanium sputtering targets are used across various industries, especially in coating, semiconductor, and optical fields. The target is primarily used for evaporation in a vacuum and deposition as a coating, commonly applied in wear protection, decorative coatings, and high-precision semiconductor and optical coatings. Due to its excellent biocompatibility, titanium is also widely used in surgical tools and implants. Additionally, titanium sputtering targets find significant applications in aerospace and high-end jewelry design.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | <0.005 | ppm | Zn | <0.2 | ppm | Pb | <0.5 | ppm | |||

| B | ppm | Ga | ppm | Bi | <0.5 | ppm | |||||

| F | ppm | Ge | ppm | Y | ppm | ||||||

| Na | ppm | As | <0.5 | ppm | Th | ppm | |||||

| Mg | <0.5 | ppm | Se | ppm | Er | ppm | |||||

| Al | <0.2 | ppm | Zr | <0.5 | ppm | Ru | ppm | ||||

| Si | ppm | Nb | <0.5 | ppm | Rh | ppm | |||||

| P | ppm | Mo | <0.5 | ppm | Os | ppm | |||||

| Cl | ppm | Pd | ppm | Cs | ppm | ||||||

| K | <0.2 | ppm | Ag | ppm | Cd | ppm | |||||

| Ca | <0.2 | ppm | Sn | <0.5 | ppm | ||||||

| Ti | Matrix | wt% | Sb | <0.5 | ppm | ||||||

| V | <0.5 | ppm | Ba | ppm | |||||||

| Cr | <0.5 | ppm | Hf | ppm | |||||||

| Mn | <0.5 | ppm | Ta | <0.5 | ppm | C | <5 | ppm | |||

| Fe | <0.5 | ppm | W | <0.5 | ppm | S | <5 | ppm | |||

| Co | <0.5 | ppm | Pt | ppm | O | <5 | ppm | ||||

| Ni | <0.5 | ppm | Au | ppm | N | <5 | ppm | ||||

| Cu | <0.5 | ppm | Hg | ppm | H | ppm |

new material

new material