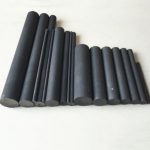

Product Overview

Graphite bars are high-purity carbon materials known for their excellent conductivity, high temperature resistance, and corrosion resistance. They are widely used in metallurgy, electrical, mechanical, and defense industries. Due to their superior properties, graphite bars can perform well under extreme conditions and are customizable to meet various industrial needs.

Key Features

- High Purity:Available in 3N to 4N purity, ensuring outstanding performance and durability.

- High-Temperature Resistance:Excellent performance in high-temperature environments, making them suitable for demanding applications.

- Good Conductivity:Ideal for electrical applications and conductivity needs.

- Chemical Stability:Strong corrosion resistance, able to withstand harsh chemicals such as strong acids and bases.

- Wear Resistance:Suitable for use in mechanical industries, providing excellent lubrication and reducing wear.

Applications

- Refractory Materials:Widely used in metallurgy for graphite crucibles, steel furnace linings, etc.

- Conductive Materials:Used in electrical industries for manufacturing electrodes, brushes, carbon rods, batteries, etc.

- Wear-Resistant Lubricants:Applied as lubricants in the mechanical industry, helping reduce wear in high-stress applications.

- Nuclear and Defense Industry:Used in the production of neutron moderators for nuclear reactors, solid-fuel rocket nozzles, missile nose cones, and other high-performance components.

| Item | 8-24 mesh |

| Iodine value(mg/g) | 800-1000 |

| Strength(%) | >94 |

| Dry reduction(%) | <10 |

| Ignition residue(%) | <5 |

| Filling proportion(g/cm3) | 0.35-0.55 |

| PH | 6~8 |

| Methylene blue value(ml) | >10 |

new material

new material