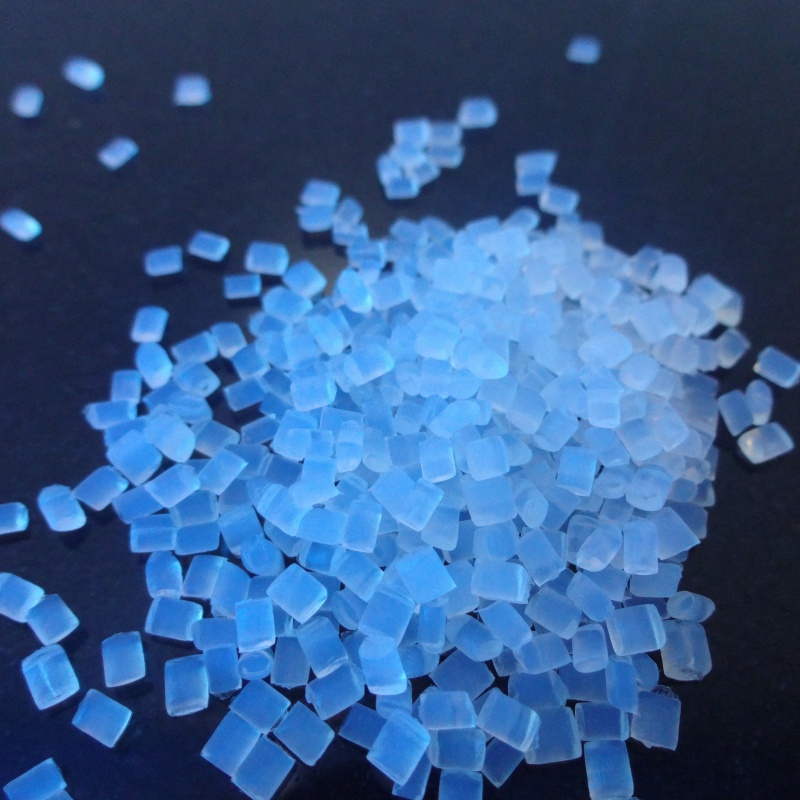

ETFE Granules provide excellent chemical resistance, high thermal stability, and superior mechanical durability. Designed for industrial coatings, wire insulation, and specialized applications, they ensure long-term performance, reliable processing, and environmental stability.

Product Overview

ETFE granules are a high-performance thermoplastic made from ethylene-tetrafluoroethylene copolymer (ETFE), known for its outstanding mechanical properties, weather resistance, flame retardancy, gas barrier properties, and chemical resistance. ETFE also features excellent radiation resistance, strong metal surface adhesion, and a lighter weight compared to other fluoropolymers. These granules can be processed using techniques such as spraying, rolling, extrusion, and injection molding, making them suitable for a wide range of applications, including corrosion-resistant linings, films, hoses, cables, and more, in industries such as chemical, agriculture, construction, electronics, and automotive.

Key Features

- High Mechanical Strength: Provides exceptional tensile strength, impact resistance, and overall mechanical performance, ensuring long-lasting use in harsh environments.

- Strong Weather Resistance: Demonstrates excellent UV, high-temperature, and oxidation resistance, making it ideal for extreme weather conditions and outdoor applications.

- Flame Retardancy: Offers superior flame retardant properties, suitable for industries with high safety requirements.

- Chemical Resistance: Resistant to most chemicals and solvents, making it ideal for corrosion protection, linings, and other applications in the chemical industry.

- Radiation Resistance: Stable in radiation environments, making it suitable for nuclear energy and other specialized fields.

- Lightweight and High Strength: Provides a lightweight material that maintains exceptional strength and durability.

- Excellent Metal Adhesion: Strong adhesion to metal surfaces, ideal for coating applications.

Applications

- Chemical Industry: Used for corrosion-resistant linings and linings for chemical equipment, offering protection against corrosion and high temperatures.

- Agriculture: Ideal for greenhouse films with excellent weather resistance and UV protection, extending the lifespan of agricultural equipment.

- Construction: Suitable for external wall coatings, roofing membranes, and other structures, offering UV protection and enhancing the durability of buildings.

- Electronics: Used as protective coatings for electronic components to ensure stable operation in harsh environments.

- Automotive: Applied as corrosion protection layers on automotive parts, improving the durability of components.

- Aerospace & Radiation Protection: Ideal for aerospace and radiation protection materials, ensuring stability in high-radiation environments.

| Test Properties | Unit | Test Method | ET8 Series | ET6 Series |

| Appearance | --- | --- | Transparent particles, free from metal chips and sand, with no more than 2% visible black spots. | Transparent particles, free from metal chips and sand, with no more than 2% visible black spots. |

| Melting Point | ℃ | D-3159 | 245–255 | 220–230 |

| Specific Gravity | g/cm³ | HG/T 2904—1997 | 1.70–1.75 | 1.76–1.85 |

| Rockwell Hardness | HB | D-2240 | 61–70 | 50–60 |

| Tensile Strength (23℃) | MPa | HG/T 2904—1997 | 30–50 | 28–45 |

| Elongation at Break (23℃) | % | HG/T 2904—1997 | 300–450 | 300–450 |

| Notched Impact Strength (23℃) | Ft-lb/in | HG/T 2904—1997 | No Break | No Break |

| Water Absorption | % | HG/T 2902—1997 | ≤0.03 | ≤0.03 |

| Oxygen Index | % | GB/T 2406-93 | 30–40 | >50 |

| Flame Retardancy | Level | GB/T 2408-2008 | V-0 | V-0 |

| Dielectric Constant | / | HG/T 2904—1997 | ≤2.4 | ≤2.4 |

| Dielectric Loss | / | HG/T 2904—1997 | 0.008 | 0.008 |

| Dielectric Breakdown Voltage (0.2mm) | kV | ASTM D149 | >7.5KV | >7.5KV |

| Glass Transition Temperature | ℃ | DMA | 80–120 | 80–120 |

| Operating Temperature | ℃ | UL-746 | -50 to 150 | -50 to 150 |

new material

new material