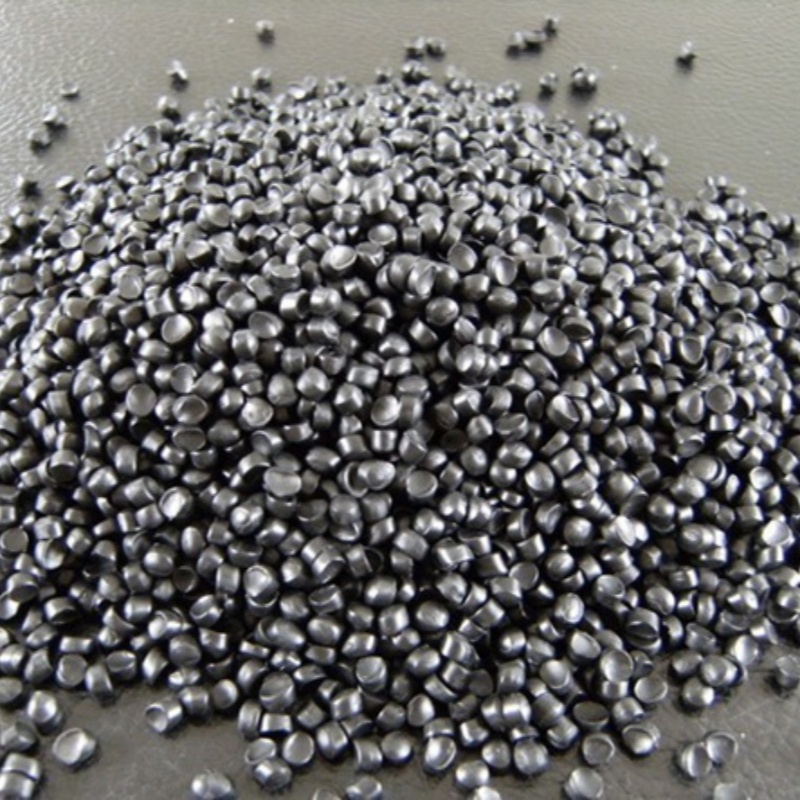

NBR/PVC Rubber-Plastic Blending Material combines the elasticity of NBR with the durability of PVC, offering excellent oil resistance, superior mechanical strength, and enhanced thermal stability. Ideal for sealing applications, automotive components, and industrial insulation.

Product Description:

NBR/PVC Rubber-Plastic Blending Material is a high-performance material made from polyvinyl chloride (PVC) as the main ingredient, combined with varying amounts of modifiers, plasticizers, and other additives. This product can be customized to achieve a Shore hardness range of A55-A95, offering excellent processing performance and good physical properties. It is widely used in manufacturing products with varying hardness and specific performance requirements.

Product Features:

- Wide Hardness Range:Hardness can be flexibly adjusted between Shore A55 and A95, meeting a variety of application needs.

- Excellent Processing Performance:Good moldability and compatibility with multiple processing techniques, making it easy to produce various products.

- High Strength and Elasticity:Provides high strength and elasticity, ensuring stable performance over long-term use.

- Customization Flexibility:Hardness, elasticity, and durability can be tailored to meet specific customer requirements and application scenarios.

- Wear and Aging Resistance:Offers good wear resistance and anti-aging properties, ensuring suitability for long-term use.

Applications:

- Automotive Industry:Used for automotive seals, gaskets, O-rings, and other components, enhancing vehicle performance and comfort.

- Construction Industry:Used as sealing material for building windows and doors, offering excellent weather resistance and sealing performance in various construction environments.

- Mechanical Equipment:Applied in mechanical sealing components that require high elasticity, wear resistance, and aging resistance.

- Consumer Goods:Used for seals, gaskets, and protective covers in everyday consumer products, providing durability and comfort.

new material

new material