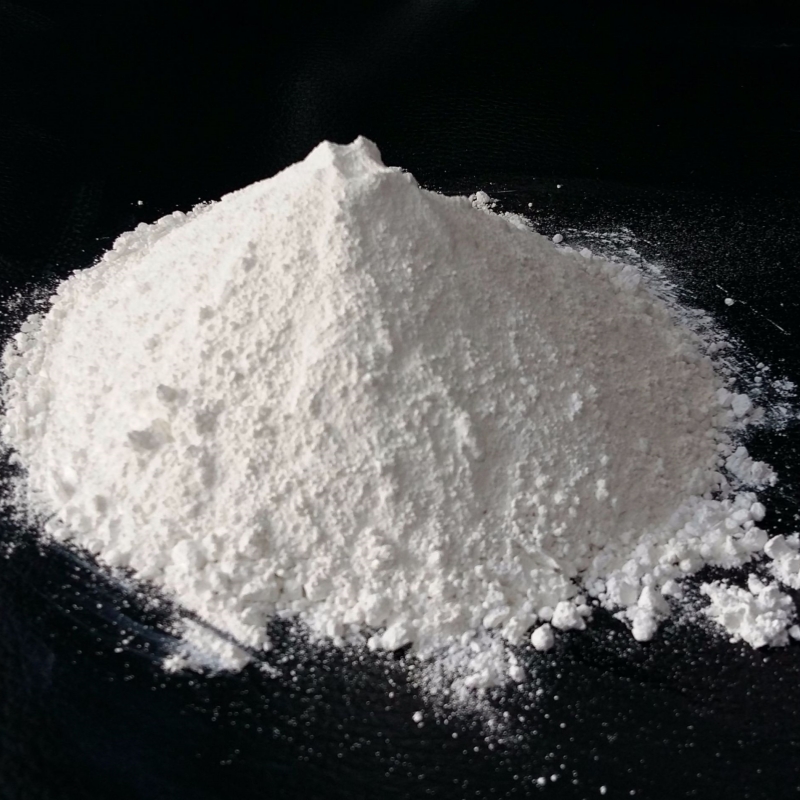

Hydrophilic titanium dioxide (TiO₂) provides optimized water affinity, superior dispersion stability, and enhanced photocatalytic activity. Designed for coatings, self-cleaning surfaces, and environmental applications, it ensures efficient moisture interaction, extended durability, and high adaptability.

Product Overview

Hydrophilic titanium dioxide is a high-purity TiO₂ product prepared through a vapor-phase (pyrolysis) method. It features ultrafine particle size, high purity, and a high specific surface area, with a mixed crystal structure consisting of anatase and rutile forms. This unique structure gives it superior performance in catalysis and photocatalysis, and it is widely used in the manufacturing of ultraviolet (UV) shielding materials.

Key Features

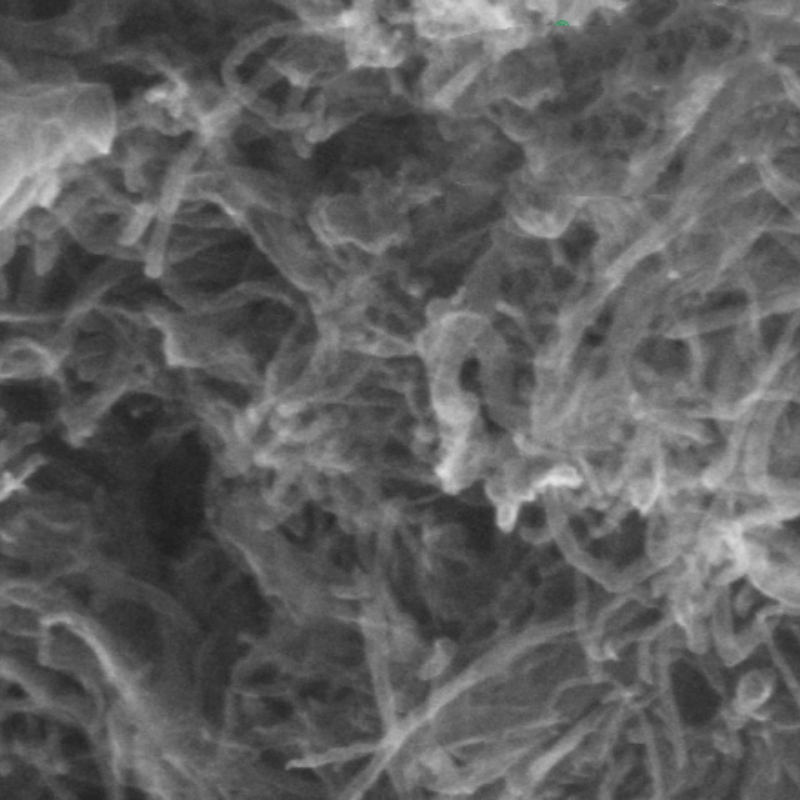

- Small Particle Size: The ultrafine particle size offers a significantly larger specific surface area, improving its reactivity and efficiency in various applications.

- Anatase and Rutile Mixed Crystal Structure: Primarily anatase with combined advantages from both the anatase and rutile forms of TiO₂.

- Good Thermal and Chemical Stability: Ensures durability and resilience in various environmental conditions, making it suitable for a range of industrial applications.

- Excellent Catalytic and Photocatalytic Efficiency: Widely used in catalytic and photocatalytic reactions to enhance reaction efficiency.

- UV Sensitivity: Effectively absorbs ultraviolet light, making it ideal for use in UV shielding materials.

- Improved Heat Stability in Silicone Rubber: Enhances the heat resistance of silicone rubber, improving its performance at high temperatures.

Applications

- Catalyst Support: Used as a high-temperature and hydrothermal stable support material for catalysts in chemical reactions.

- Photocatalytic Self-Cleaning Building Materials: Applied in self-cleaning construction materials, where photocatalytic properties help degrade pollutants.

- Dye-Sensitized Solar Cells: Serves as a key material in efficient dye-sensitized solar cells, improving photoelectric conversion efficiency.

- Heat Stabilizer and Flame Retardant for Silicone Rubber: Used to enhance the heat stability and flame retardancy of silicone rubber.

- Binder for Ceramics and Metals: Acts as a binder and sintering additive for ceramics and metals, improving their strength and durability.

- Cathode Material for Lithium-Ion Batteries: Used as a dry coating material for cathodes in lithium-ion batteries, boosting performance and lifespan.

| Parameter | Unit | Typical Value |

| Specific surface area (BET method) | m²/g | 50±15 |

| pH value of 4% suspension | - | 3.5-4.5 |

| Loss on drying | wt.% | ≤1.5 |

| Tapped density* | g/l | 140±40 |

| TiO₂ content (based on calcined material) | wt.% | ≥99.5 |

| Al₂O₃ content (based on calcined material) | wt.% | ≤0.300 |

| SiO₂ content (based on calcined material) | wt.% | ≤0.200 |

| Fe₂O₃ content (based on calcined material) | wt.% | ≤0.010 |

| HCl content (based on calcined material) | wt.% | ≤0.300 |

| 45μm sieve residue | wt.% | - |

new material

new material