Iron carbide (Fe₃C) offers optimized hardness, superior wear resistance, and enhanced thermal stability. Designed for metallurgical, catalytic, and energy applications, it ensures efficient carbon incorporation, extended durability, and high adaptability.

Product Overview

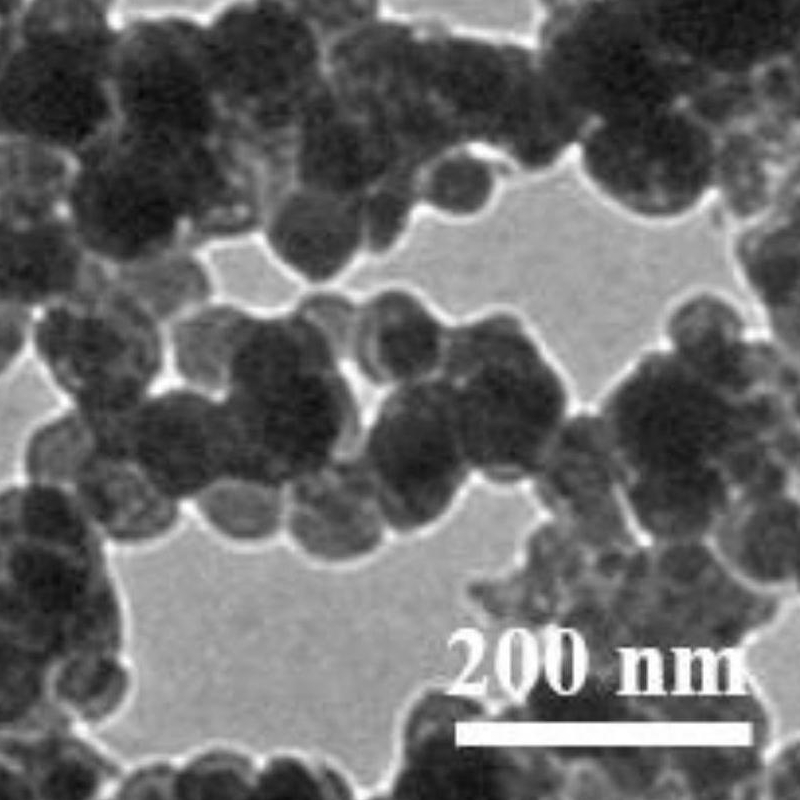

Iron carbide (Fe₃C) is a common chemical compound composed of iron and carbon, typically appearing as gray-black irregular particles. It plays a significant role in the industrial sectors, especially in steelmaking and alloy preparation, where it enhances the properties of materials.

Key Features

- High Purity: Offers a high degree of purity, ensuring stability and reliability in various applications.

- Irregular Particles: The irregular particle shape is suitable for diverse processing and application needs.

- Good Chemical Stability: Exhibits good stability under normal conditions and is resistant to unwanted chemical reactions.

Applications

- Steel Industry: Iron carbide is widely used in the manufacture of steel alloys, serving as a carbon source to enhance hardness and strength.

- Alloy Materials: Iron carbide is an essential component in various alloy materials, improving their performance.

- Heat Treatment: Used as a strengthening material in heat treatment processes to improve the hardness and wear resistance of metals.

| Parameter | Description |

| Diameter | 0.2-0.7 μm |

| Length | 10-35 μm |

| Appearance | Gray powder |

| Purity | >99 at% |

new material

new material