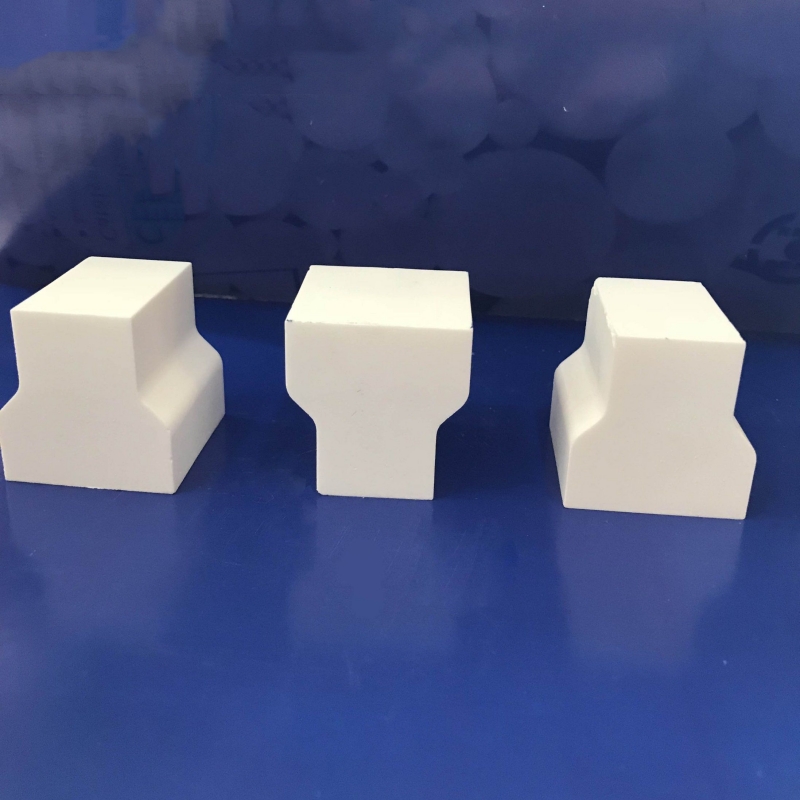

Al₂O₃ wear-resistant ceramic blocks offer exceptional hardness, optimized abrasion resistance, and superior thermal stability. Designed for industrial applications, they ensure reliable protection, extended lifespan, and consistent operational efficiency.

Product Overview:

The Al₂O₃ wear-resistant ceramic block is crafted from high-purity aluminum oxide material using advanced manufacturing processes. It features exceptional hardness and wear resistance, ensuring long-term, reliable performance in harsh working environments. This product is ideal for applications requiring high wear resistance and impact resistance, such as equipment protection and support in the mechanical, mining, and metallurgy industries.

Product Features:

- High Hardness:Rockwell hardness of HRA 80-90, second only to diamond, significantly outperforming wear-resistant steel and stainless steel.

- Superior Wear Resistance:Wear resistance is 266 times that of manganese steel and 171.5 times that of high-chromium cast iron, effectively extending equipment life.

- Lightweight:Density of 3.5g/cm³, only half that of steel, reducing the overall load on equipment.

- High-Temperature Resistance:Able to withstand high-temperature environments, maintaining stable physical and chemical properties in extreme conditions.

- Corrosion Resistance:Exhibits excellent resistance to acids, alkalis, and other chemical agents, making it suitable for challenging operational conditions.

Applications:

- Mechanical Industry:Used for manufacturing wear-resistant parts for heavy machinery, extending the service life of equipment.

- Mining and Metallurgy:Provides protection for equipment in mining and smelting processes, reducing wear and tear.

- Chemical Industry:Used as a corrosion-resistant and wear-resistant material in chemical production, withstanding chemical agent exposure.

- Energy Industry:Serves as high-wear-resistant components in energy extraction and processing, ensuring stable equipment performance.

- High-Temperature Equipment:Provides support and protection in high-temperature environments, such as metallurgical furnaces and heat treatment equipment.

new material

new material