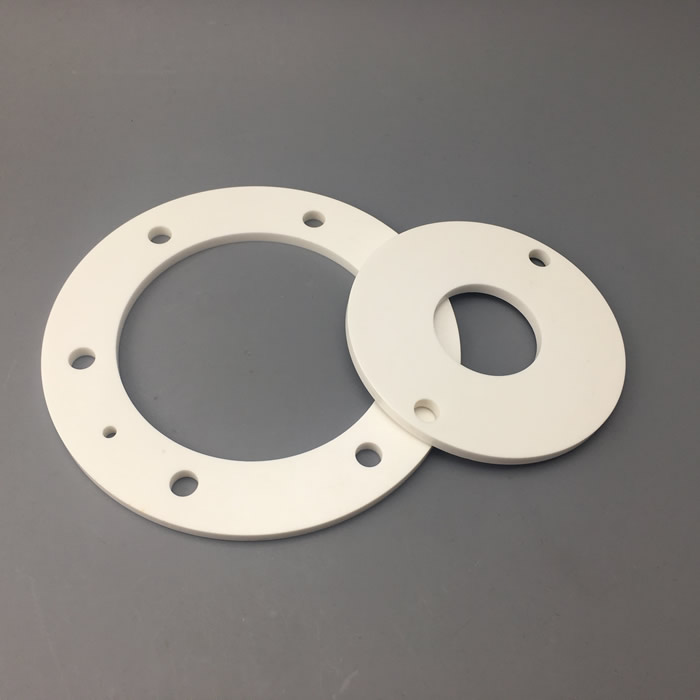

Alumina ceramic flange gaskets offer exceptional thermal stability, optimized sealing performance, and superior wear resistance. Designed for industrial applications, they ensure reliable sealing, extended durability, and enhanced structural integrity.

Product Overview:

Alumina Ceramic Flange Gaskets, also known as grooved porous ceramic rings, are specifically designed for industrial applications. Combining the excellent properties of alumina ceramics, they maintain long-term stable performance in high-pressure, high-temperature, and corrosive environments. The flange gasket features a porous design, ensuring excellent sealing and stability. Its precision-machined holes and grooves provide optimal mechanical stability and durability, making it suitable for demanding applications.

Product Features:

- Porous Design:Precision-machined holes ensure tight sealing and stability during connections, delivering optimal performance.

- High Hardness and Strength:Alumina material offers extremely high hardness and strength, ensuring the gasket maintains its shape and performance even under high pressure and friction.

- High-Temperature Resistance:Can operate at temperatures up to 1650°C, making it ideal for use in high-temperature equipment and operations.

- Corrosion Resistance:Exceptional resistance to chemical corrosion, able to withstand acids, alkalis, and other corrosive substances, ensuring stability in aggressive environments.

Applications:

- Petrochemical Industry:Used in petrochemical equipment to seal and connect high-temperature, high-pressure pipelines and reactors.

- Electronics and Electrical Equipment:Widely used in high-frequency and high-voltage devices for electrical connections and insulation components.

- Mechanical Manufacturing:Suitable for mechanical equipment that operates under high pressure and wear conditions, providing excellent sealing and wear resistance.

new material

new material