Microcrystalline wear-resistant alumina liner bricks offer exceptional hardness, optimized abrasion resistance, and superior thermal stability. Designed for industrial applications, they ensure reliable protection, extended lifespan, and consistent operational efficiency.

Product Overview:

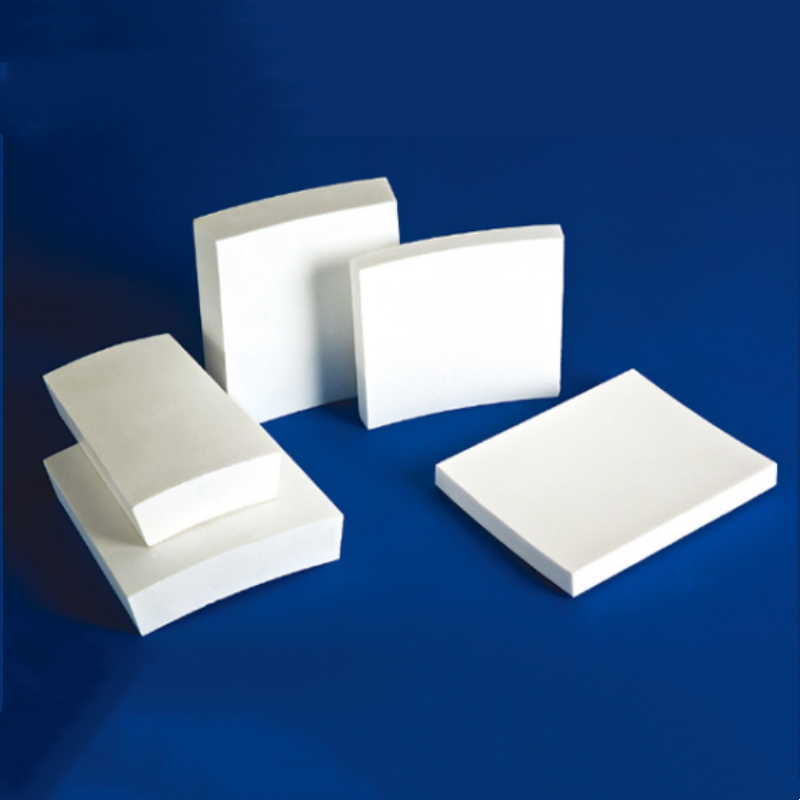

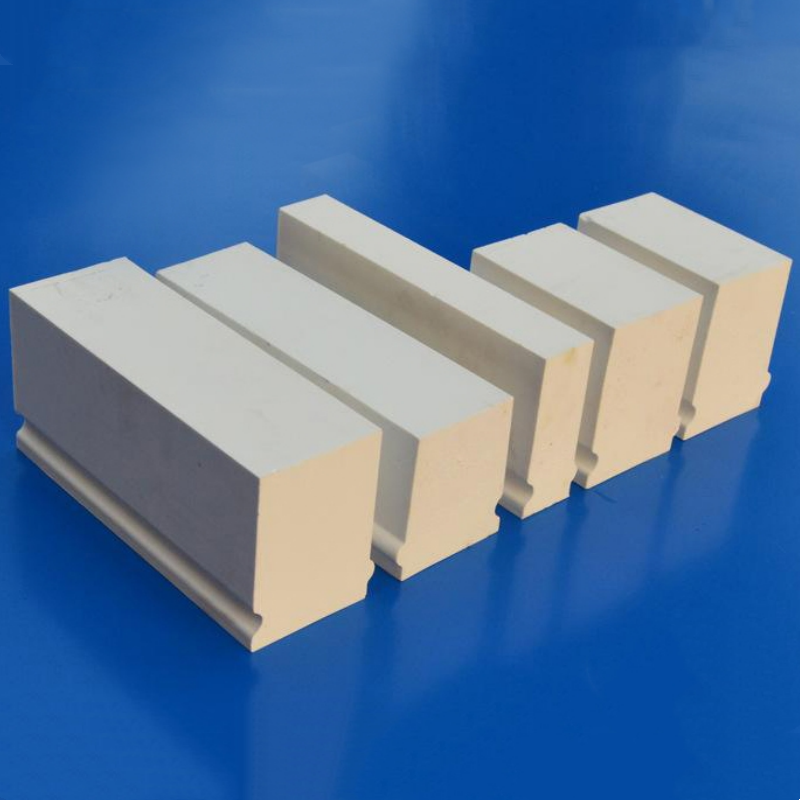

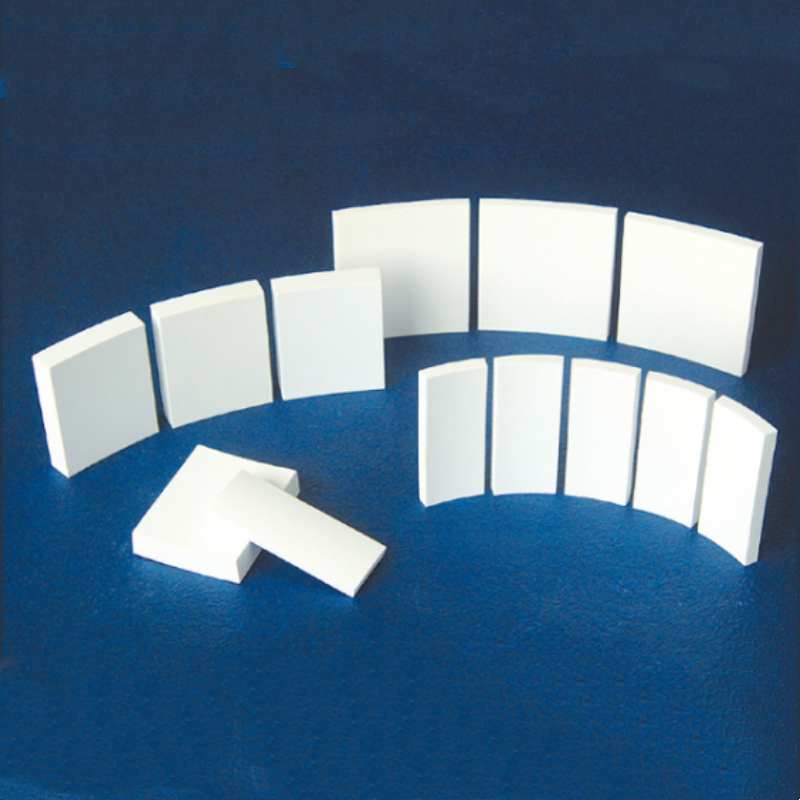

The Microcrystalline Wear-Resistant Alumina Liner Bricks are made from high-purity alumina materials, offering excellent wear resistance, corrosion resistance, and high-temperature stability. They are widely used for wear protection in ball mills, extending equipment life, and improving material grinding purity. With a variety of shapes and precise tolerances, these bricks are ideal for protecting industrial equipment in high-wear environments. We also provide professional installation services to ensure optimal performance.

Product Features:

- High Hardness:With a Mohs hardness of 9.0, these bricks are suitable for high-intensity wear environments.

- High Density:The high density provides stronger compressive strength and wear resistance.

- Low Wear Rate:Under high-wear conditions, they exhibit a low wear rate, significantly extending equipment life.

- Impact Resistance:Excellent resistance to impact, effectively protecting equipment from high-speed operation and external forces.

- Corrosion Resistance:Resistant to acid and alkali corrosion, making them suitable for various chemical environments.

- High Purity and Contamination-Free:Made from high-purity alumina, these bricks ensure no contamination of the ground materials, preserving purity during grinding.

Applications:

- Ball Mill Protection:Primarily used for wear protection in ball mills, these bricks extend the life of the mill and ensure the purity of the materials being ground.

- Mining Industry:Widely used in mineral processing and material grinding to prevent equipment wear and extend service life.

- Metallurgy:Applied in the grinding of abrasives and protection in high-wear environments within the metallurgy industry.

- Chemical Industry:Used in efficient material grinding and material transport systems within the chemical industry, providing enhanced wear and corrosion protection.

| Performance Product | 92 Series | 95 Series | 97 Series | 99 Series |

| Al₂O₃ (%) | ≥92 | ≥95 | ≥97 | ≥99 |

| Mohs Hardness | 9 | 9 | 9 | 9 |

| Water Absorption (%) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Bulk Density (g/cm³) | ≥3.63 | ≥3.68 | ≥3.73 | ≥3.83 |

| Abrasion (%-24 hours) | ≤0.010 | ≤0.005 | ≤0.010 | ≤0.010 |

| Name | Length (L) mm | Width (W1) mm | Width (W2) mm | Thickness (H) mm | |

| 40-90mm Lining Brick | Straight Brick | 150±2 | 50±1 | 50 | 40/50/60/70/77/90±1 |

| Angled Brick | 150±2 | 50±1 | 45±1 | 40/50/60/70/77/90±1 | |

| Half-Straight Brick | 75±1 | 50±1 | 50±1 | 40/50/60/70/77/90±1 | |

| Angled Half Brick | 75±1 | 50±1 | 45±1 | 40/50/60/70/77/90±1 | |

| Thin Brick | 150±2 | 25±1 | 22.5±1 | 40/50/60/70/77/90±1 | |

| Special Lining Bricks | 80×50×55 | 55±2 | 50±1 | 50±1 | 80±1 |

| 100mm Lining Brick | 75±1 | 45±1 | 41±1 | 110±2 | |

| 110mm Half Lining Brick | 37.5±1 | 45±1 | 41±1 | 110±1 | |

| Polished Brick | Custom-made as per customer requirement | ||||

new material

new material