Fan-shaped perforated alumina ceramic plates offer exceptional thermal stability, optimized mechanical strength, and superior filtration efficiency. Designed for industrial applications, they ensure precise fluid control, extended lifespan, and reliable performance.

Product Overview:

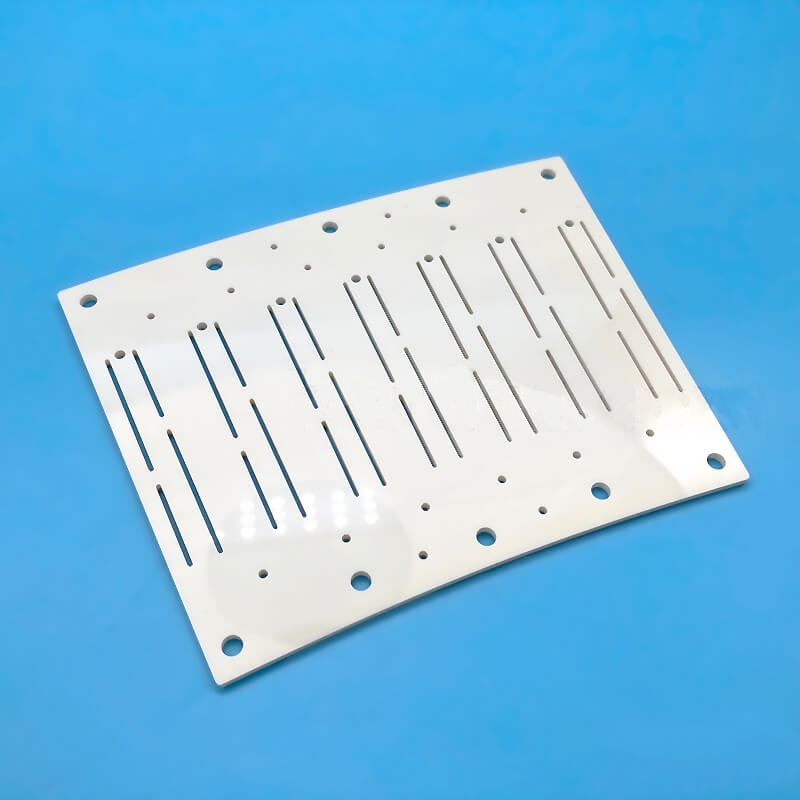

The Fan-Shaped Perforated Alumina Ceramic Plate, also known as a laser-cut ceramic sheet, is a complex alumina (Al₂O₃) ceramic plate made using precision laser cutting technology. This plate is widely used in electronics, medical devices, industrial machinery, and filtration systems due to its high-precision hole diameters and intricate pattern designs, making it ideal for specialized functional requirements. The use of laser cutting technology offers remarkable flexibility in design and precision, helping optimize thermal management, weight, and structural strength.

Product Features:

- Precision Perforation and Hollow Design:Made with laser cutting technology, it offers high-precision holes and intricate patterns that meet specific technical requirements.

- High Hardness and Wear Resistance:Alumina ceramics provide exceptional hardness (up to 82 Rockwell) and wear resistance (15.7 GPa Vickers hardness), ensuring excellent durability and scratch resistance.

- Excellent Thermal Stability and Electrical Insulation:The material can withstand temperatures up to 1650°C and exhibits outstanding electrical insulation properties, making it suitable for high-temperature electronic devices.

- Capability for Complex Structures:Laser cutting technology enables the creation of intricate geometric structures and micro-adjustments, accommodating various custom needs.

- Enhanced Structural Strength and Thermal Management:The porous design reduces weight while improving heat transfer and airflow dynamics, enhancing overall equipment performance.

Applications:

- Electronics:Used as a heat dissipation layer or electrical insulation in applications such as processor cooling systems or high-power LED devices.

- Medical Devices:Utilized in medical equipment requiring precision and hygiene, ensuring reliability and stability in sensitive environments.

- Industrial Machinery:Serves as a mechanical component providing structural support in high-temperature, chemically stable environments.

- Filtration Systems:The precision hole structure makes it suitable for liquid or gas filtration, widely used in chemical processing and fine chemical industries.

new material

new material