Porous precision alumina ceramic filter elements offer exceptional filtration efficiency, optimized thermal stability, and superior chemical resistance. Designed for industrial and environmental applications, they ensure reliable filtration, extended lifespan, and consistent operational performance.

Product Overview:

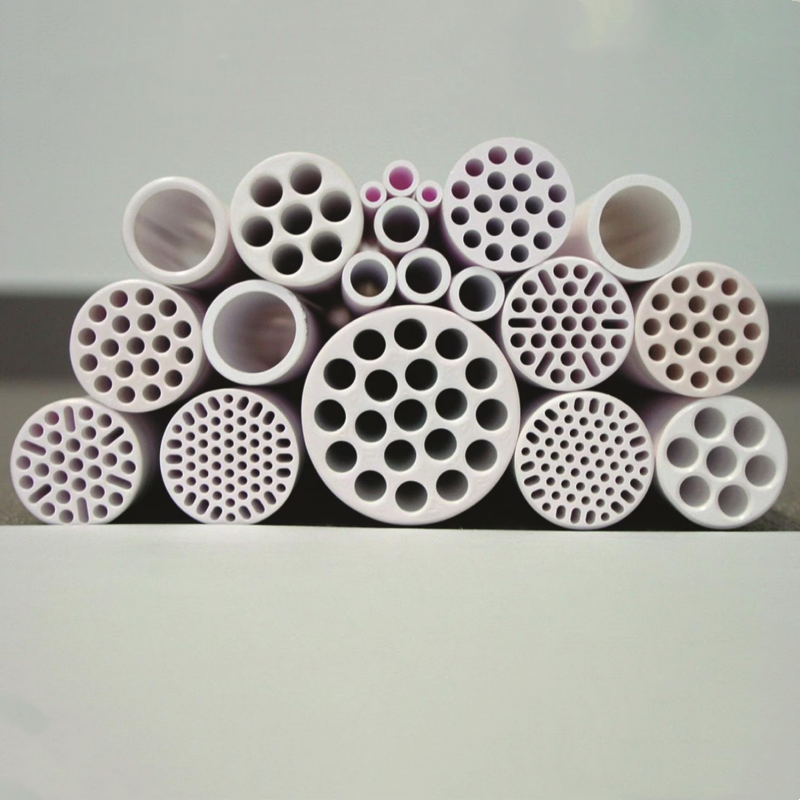

The Porous Precision Alumina Ceramic Filter Element, also known as the ceramic honeycomb piston, is a high-performance filtration component made from alumina (Al₂O₃) ceramic material. Featuring a porous structure design, it delivers exceptional filtration and separation performance in high-temperature and chemically aggressive environments. This filter element is widely used in industrial processes requiring efficient purification, particularly in chemical processing, biotechnology, environmental protection, and the food industry. Its key advantages include high mechanical strength, excellent thermal and chemical stability, as well as good thermal and electrical insulation properties.

Product Features:

- High Mechanical Strength and Wear Resistance:Alumina ceramic offers a Vickers hardness of 15.7 GPa and a bending strength of up to 330 MPa, ensuring long lifespan and stability even under high load conditions.

- Excellent Heat and Chemical Stability:Able to withstand temperatures up to 1650°C, the ceramic filter element is chemically inert, making it ideal for high-temperature and corrosive environments.

- Efficient Filtration Performance:The porous structure increases the surface area of the filtration medium, enhancing filtration efficiency while reducing pressure loss and optimizing fluid dynamics.

- Superior Thermal and Electrical Insulation:The filter has low thermal conductivity and high electrical breakdown strength, making it suitable for applications requiring electrical insulation.

- Customizable Design:Custom shapes and sizes can be tailored to meet the specific requirements of different filtration systems and installations.

Applications:

- Chemical Processing:Used in chemical plants to filter corrosive chemicals, enhancing production safety and product purity.

- Biotechnology:Applied in bioreactors to ensure the purification of culture media and biological products, widely used in pharmaceutical and biological research.

- Flue Gas Purification:Used in environmental protection equipment to filter harmful gases and particulates, helping reduce industrial emissions' environmental impact.

- Food and Beverage Industry:Applied in production processes to filter food products or liquids, ensuring the safety and cleanliness of the final product.

new material

new material