Zirconia ceramic guide blocks offer exceptional wear resistance, optimized mechanical stability, and superior thermal durability. Designed for industrial applications, they ensure precise alignment, extended lifespan, and reliable performance in demanding environments.

Product Overview:

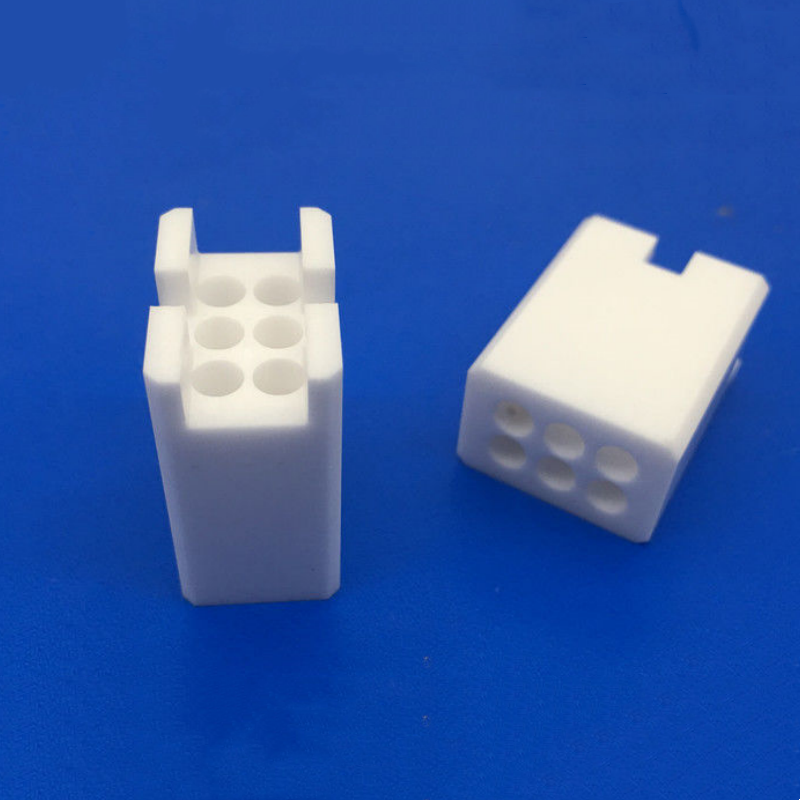

Zirconia Ceramic Guide Blocks (also known as Electrical Protection Ceramic Terminals) are critical components designed for electric heating equipment and high-temperature industrial applications. Their complex geometric shapes and multiple hole designs ensure precise positioning and fixation within the equipment. With high hardness, strength, exceptional electrical insulation, and high-temperature resistance, these guide blocks maintain their shape and performance under high-pressure, high-temperature, and high-friction environments, ensuring the stability and longevity of the equipment.

Product Features:

- Complex Geometry & Porous Design:Precision-engineered to provide accurate positioning and fixation, adapting to complex mechanical structures.

- Superior Mechanical Properties:With high Rockwell hardness (R45N 78) and compressive strength (2000 MPa), these blocks maintain stable performance under high-pressure and high-friction conditions.

- Excellent Electrical Insulation:Maintains electrical insulation performance in high-voltage environments, preventing electrical faults and enhancing equipment safety.

- High Heat Resistance:Outstanding thermal conductivity (2.5 W/(m·K)) and thermal shock resistance (ΔT 250°C), allowing the guide blocks to maintain performance and structural stability in high-temperature operating conditions.

Applications:

- Electric Heating Equipment:Used in electric heaters, heat exchangers, and other equipment to provide electrical insulation and optimize thermal management.

- Industrial Machinery:Critical components for accurate positioning and fixation of mechanical parts in high-strength, high-temperature industrial environments.

- High-Temperature Electronic Components:Provides electrical insulation and thermal management in power electronics equipment.

- Medical and Scientific Instruments:Ideal for medical devices and scientific instruments, ensuring strict electrical insulation and precise control, safeguarding operational safety and accuracy.

new material

new material