Trapezoidal zirconia ceramic blades offer exceptional hardness, optimized wear resistance, and superior thermal stability. Designed for precision cutting applications, they ensure sharp edges, extended durability, and high-performance efficiency in demanding environments.

Product Overview:

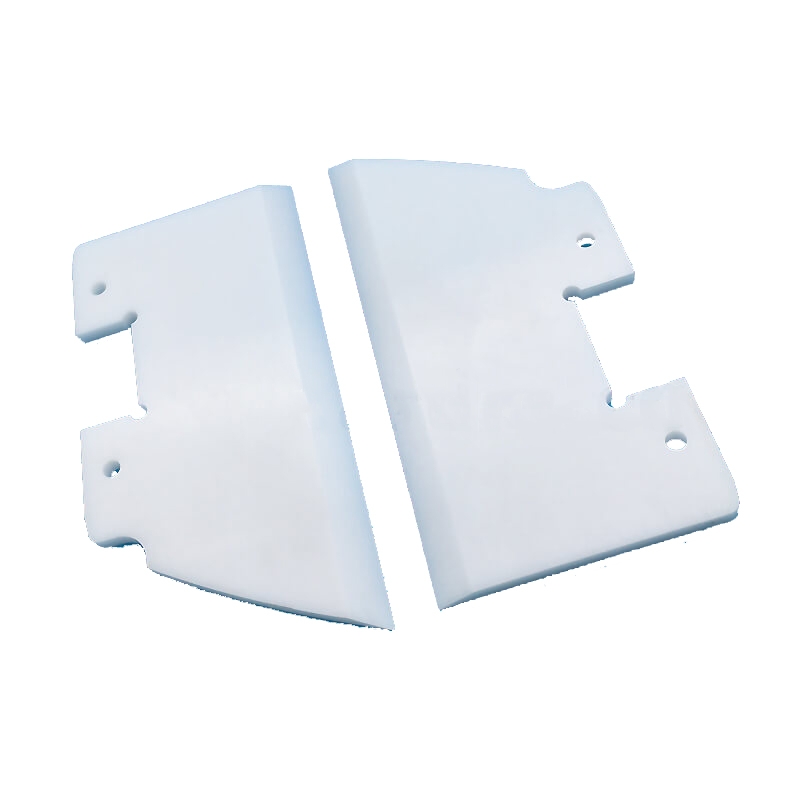

Trapezoidal Zirconia Ceramic Blades (also known as Waist Hole Industrial Blades) are high-performance blades designed for industrial applications requiring precision and high durability. These blades feature a unique trapezoidal design with precisely engineered waist holes that ensure the blades are securely positioned within machinery, providing cutting stability and accuracy even under high loads and high-speed operation conditions. The high fracture toughness, heat resistance, and corrosion resistance of zirconia ceramics make these blades ideal for demanding environments, especially in precision cutting and micro-machining.

Product Features:

- Trapezoidal Design:Enhances cutting stability and accuracy by increasing the contact area, providing superior mechanical support for the blade.

- Waist Hole Structure:Ensures precise alignment and secure fixation of the blade in machinery, making it suitable for high-speed and high-pressure operations.

- High-Performance Material:Made from zirconia with high fracture toughness (9 MPa·m¹/₂) and compressive strength (2000 MPa), ensuring durability and stability under extreme conditions.

- Chemical & Thermal Stability:Excellent corrosion resistance and thermal stability (thermal shock resistance coefficient of 250°C), making it suitable for high-temperature environments.

- Self-Lubricating Properties:Reduces wear and extends the lifespan of both the blade and the equipment.

Applications:

- Electronics Manufacturing:Used in the precise cutting and micro-machining of semiconductor and precision electronic components, ensuring compliance with strict dimensional and quality standards.

- Medical Devices:Ideal for manufacturing precision medical parts such as surgical instruments and implants, offering accurate cutting and shaping.

- High-Precision Industrial Equipment:Employed in aerospace, automotive manufacturing, and high-end mechanical engineering for precision machining of critical components.

new material

new material