Magnesium-doped zirconia ceramic rods offer enhanced mechanical strength, optimized thermal stability, and superior wear resistance. Designed for high-performance applications, they ensure reliable durability, precision control, and extended service life in demanding environments.

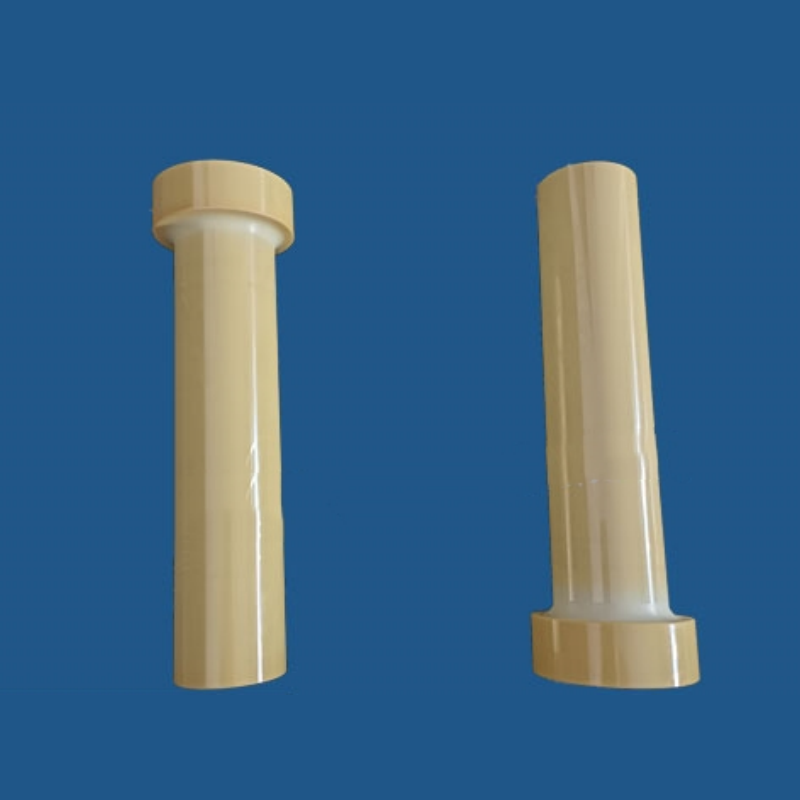

Product Overview:

Magnesium-doped zirconia ceramic rods are made by combining magnesium with zirconia, offering superior wear resistance, high-temperature stability, chemical corrosion resistance, and anti-magnetic properties. This composite material performs excellently in harsh environments and does not contaminate the material or surroundings. The addition of magnesium enhances the zirconia’s stability and toughness at high temperatures, improves its bending strength, and boosts its wear resistance. It is widely used in industries with high demands.

Product Features:

- Wear Resistance:Especially suitable for long-term use with excellent wear resistance.

- High Temperature Resistance:Can operate stably under extremely high temperatures.

- Chemical Corrosion Resistance:Adapts to a variety of corrosive environments.

- High Toughness and Bending Strength:Ensures stability under mechanical loads.

- Excellent Thermal Insulation:Effectively prevents heat transfer.

- Anti-Magnetic Properties:Suitable for applications where magnetic field interference must be avoided.

- Thermal Expansion Coefficient Close to Steel:Increases compatibility with other materials.

Applications:

- High-Temperature Equipment:Used in high-temperature environments such as smelting and chemical reactions.

- Electronics Industry:Applied in high-precision electronic components, protective and conductive components.

- Chemical and Pharmaceutical Industries:Used in corrosion-resistant pipes, reactors, and other equipment.

- Mechanical Manufacturing:Ideal for high-strength, wear-resistant parts such as bearings and seals.

- Aerospace:Serves as a protective and thermal insulation material in high-temperature environments.

new material

new material