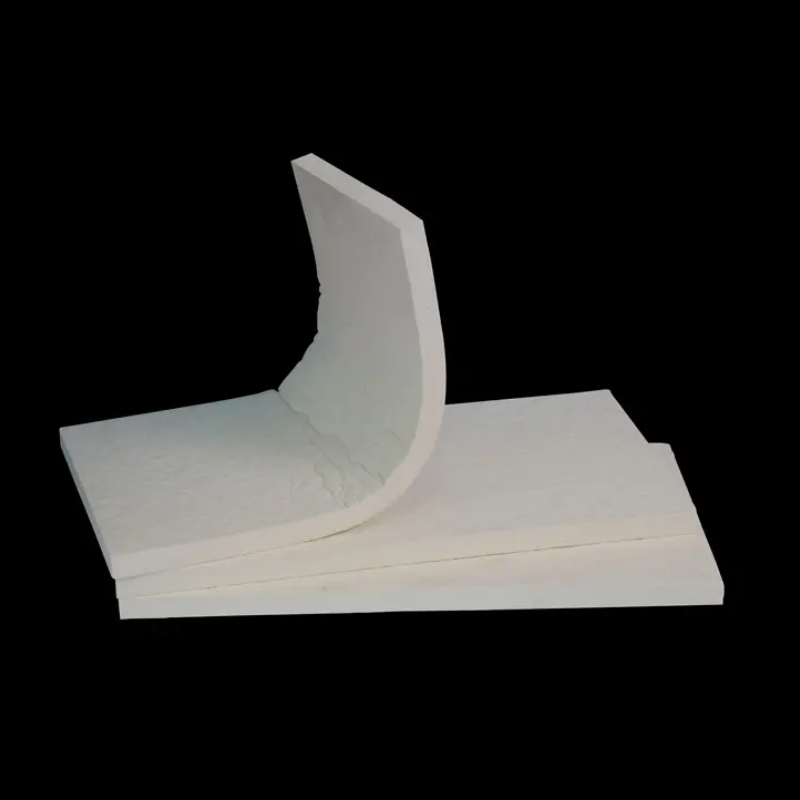

Boron nitride fiber felt offers exceptional thermal insulation, optimized chemical resistance, and superior mechanical stability. Designed for high-temperature applications, it ensures reliable structural integrity, extended lifespan, and efficient thermal management.

Product Overview

Boron nitride fiber felt is a high-performance specialty ceramic fiber material known for its exceptional high-temperature resistance, low dielectric loss, low thermal conductivity, good machinability, flame-retardant, and insulating properties. This product maintains excellent performance under extreme working conditions, making it ideal for applications in high-temperature and ultra-high-temperature environments, as well as for use as a substrate for wave-transparent materials. Boron nitride fiber felt plays a crucial role in aerospace, military protection, and high-tech fields.

Features

- High-Temperature Resistance: Capable of withstanding extremely high temperatures, suitable for high or ultra-high temperature environments.

- Low Dielectric Loss: Exhibits very low dielectric loss, making it ideal for high-frequency applications.

- Low Thermal Conductivity: Effectively reduces heat transfer, suitable for insulation and thermal management applications.

- Good Machinability: Easily processed into various shapes and sizes, meeting diverse requirements.

- Flame Retardant: Prevents fire spread, ensuring safe use.

- Electrical Insulation: Provides excellent electrical insulation protection, making it suitable for electrical applications.

Applications

- Wave-Transparent Material Substrate: Used to manufacture wave-transparent materials, widely applied in high-tech fields.

- High and Ultra-High Temperature Thermal Insulation: Provides effective insulation and heat retention, ideal for high-temperature insulation needs.

- Aerospace: Used in spacecraft and other high-temperature environments for insulation and thermal protection.

- Military Protection: Serves as a key material in high-performance protective equipment.

| Surface Density (g/m²) | 4000±50 |

| Temperature Resistance (°C) | 1600 (Inert Atmosphere) |

| Thickness (mm) | 35±3 |

| Moisture Content (%) | ≤1 |

| Combustible Content (%) | ≤1 |

| Thermal Conductivity (W/m·K) | 0.068 (500°C) |

new material

new material