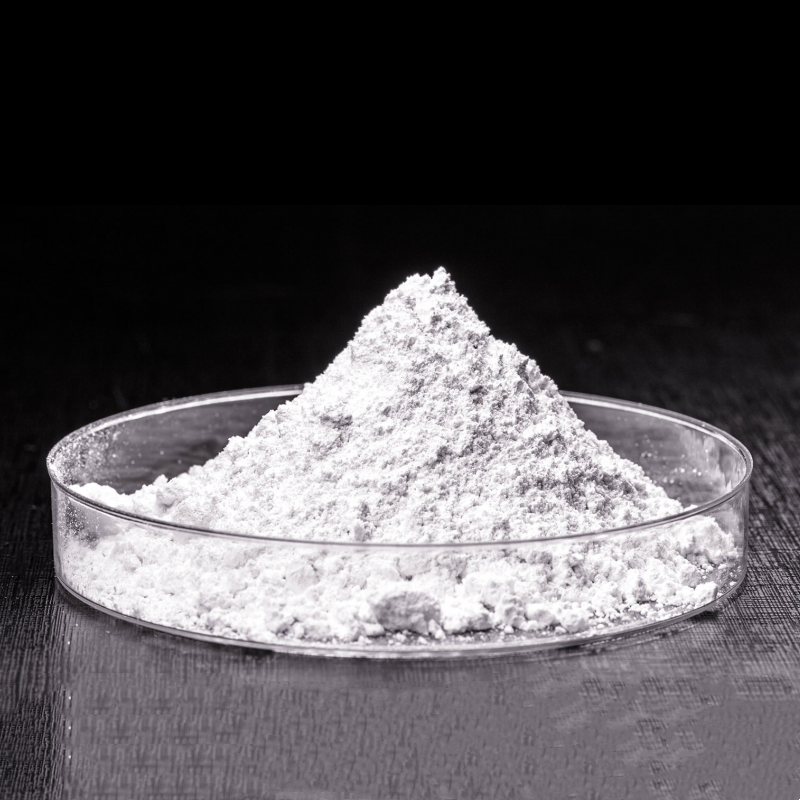

Hydrophilic fumed silica is a high-purity, amorphous silica material characterized by its extremely fine particle size, large surface area, and strong affinity for water. Manufactured through flame hydrolysis, it provides superior dispersion, enhanced rheological control, and improved thickening properties in various applications. This versatile silica is widely used in adhesives, coatings, sealants, personal care formulations, and pharmaceuticals, offering excellent moisture absorption, anti-caking functionality, and stability enhancement.

Product Overview

Hydrophilic Fumed Silica is a high-purity white powder with excellent rheological and thixotropic properties. It is widely used as a reinforcing filler in high-temperature vulcanized silicone rubber (HTV) and room-temperature vulcanized silicone rubber (RTV), as well as in coatings, paints, and adhesives. The product significantly enhances thickening, anti-settling, and powder flowability. During transport and storage, care should be taken to avoid moisture, compression, and packaging damage to ensure long-term stability.

Key Features

- High Purity: Ensures superior performance and consistency.

- White Powder: Easily disperses and integrates into various systems.

- Excellent Rheological and Thixotropic Properties: Performs exceptionally well in adhesives and sealants.

- Anti-Settling, Thickening Effect: Improves powder flowability and enhances material processing performance.

Applications

- HTV and RTV Silicone Rubber: Used as a reinforcing filler to enhance the strength and durability of elastomers.

- Adhesives and Sealants: Acts as a rheology and thixotropy agent to improve workability and application performance.

- Coatings and Paints: Enhances powder flowability, prevents settling, thickens, and improves coating quality.

| Grade | A-150 | A-200 | A-250 | A-300 | A-380 |

| SiO₂ Content (wt%) | 99.80% | 99.80% | 99.80% | 99.80% | 99.80% |

| Loss on Drying (2h@105℃) | ≤ 2.5 | ≤ 2.5 | ≤ 2.5 | ≤ 2.5 | ≤ 2.5 |

| Suspension pH | 3.8~4.5 | 3.8~4.5 | 3.8~4.5 | 3.8~4.5 | 3.8~4.5 |

| Specific Surface Area (BET)m2/g | 130~170 | 180~220 | 226~275 | 276~335 | 336~405 |

new material

new material