Titanium Silicalite (TS) is a high-performance molecular sieve catalyst featuring titanium-incorporated MFI or MEL-type zeolite structures. This material exhibits excellent oxidation and epoxidation catalytic activity, making it highly effective in selective oxidation reactions, particularly in the production of propylene oxide via the direct oxidation of propylene using hydrogen peroxide. With superior thermal stability, controlled acidity, and high catalytic efficiency, Titanium Silicalite is widely applied in fine chemical synthesis, petrochemical refining, and large-scale industrial oxidation processes.

Product Overview

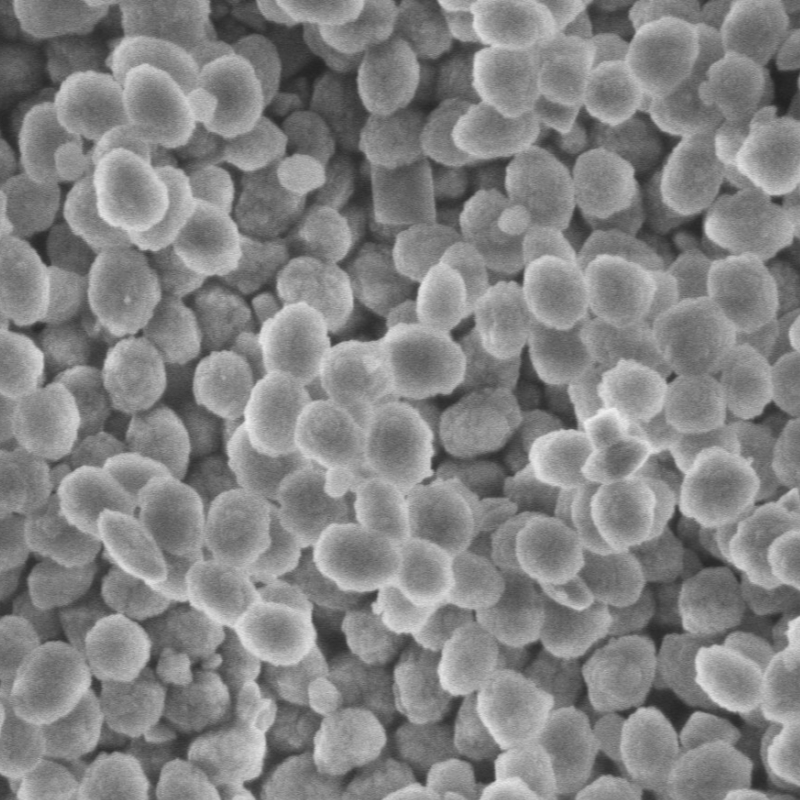

Titanium Silicalite (TS) is a titanium-silicon molecular sieve with an MFI topology, synthesized using a hydrothermal method. It features an orthorhombic crystal system with a framework comprising zigzag and elliptical straight channels, similar to ZSM-5 zeolite. The four-coordinate titanium ions in TS serve as the active sites for catalytic oxidation reactions. Due to the uniform distribution of titanium atoms in the framework, special Si-O-Ti bonds are formed, imparting unique catalytic properties. Unlike traditional acidic zeolites, TS does not contain strongly acidic aluminum ions in its framework, making it highly hydrophobic and particularly suited for selective oxidation reactions of organic compounds in the presence of hydrogen peroxide (H₂O₂).

Key Features

- Exceptional Catalytic Performance: Titanium ions in the framework act as active sites, providing excellent catalytic oxidation properties.

- Shape-Selective Catalysis: The three-dimensional pore structure, similar to ZSM-5, enables selective catalysis for specific organic reactions.

- Strong Hydrophobicity: The absence of strongly acidic aluminum ions in the framework enhances its resistance to moisture.

- Excellent Reaction Selectivity: Provides unique catalytic performance for partial oxidation of various organic compounds, especially in H₂O₂-mediated reactions.

- Ease of Use: After calcination, TS is ready for catalytic reactions and is easy to handle in various processes.

Applications

- Epoxidation of Olefins: Widely used in the epoxidation of olefins to produce epoxides, a key step in the production of specialty chemicals.

- Ammoxidation of Cyclohexanone: Applied in the ammoxidation of cyclohexanone, important in nylon production and related industries.

- Oxidation of Alcohols: Catalyzes oxidation reactions of alcohols, converting them efficiently into valuable chemical intermediates.

- Oxidation of Saturated Hydrocarbons: Used for the oxidation of saturated hydrocarbons, enhancing product selectivity.

- Hydroxylation of Aromatic Hydrocarbons: Catalyzes the hydroxylation of aromatic compounds such as benzene and phenol, aiding in the synthesis of high-value-added products.

| Item | Specification | Analysis Result | Testing Method |

| Product Name (Zeolite Type) | TS Zeolite | TS Zeolite | / |

| Product Components | SiO₂/TiO₂ | SiO₂/TiO₂ | / |

| Appearance (Shape) | Powder | Powder | Visual Inspection |

| SiO₂ (m/m %) | / | / | XRF |

| TiO₂ (m/m %) | / | / | XRF |

| SiO₂/TiO₂ Ratio (mol/mol) | ≥20 | 20, 30, 40 | XRF |

| Crystallinity (%) | ≥95 | 96 | XRD |

| Surface Area (BET) (m²/g) | ≥350 | 380 | BET |

| Pore Volume (cc/g) | ≥0.2 | 0.29 | BET |

| Na₂O (m/m %) | ≤0.1 | 0.01 | XRF |

| Average Particle Size (μm) | 40~70 | 55 | / |

| Loss on Ignition (LOI) (m/m %) | ≤5 | 0.8 | 1000℃, 1h |

new material

new material