Chromium flakes are high-purity materials used in various industrial applications, including metallurgy, electroplating, and chemical production. They are known for their excellent corrosion resistance, high melting point, and unique properties.

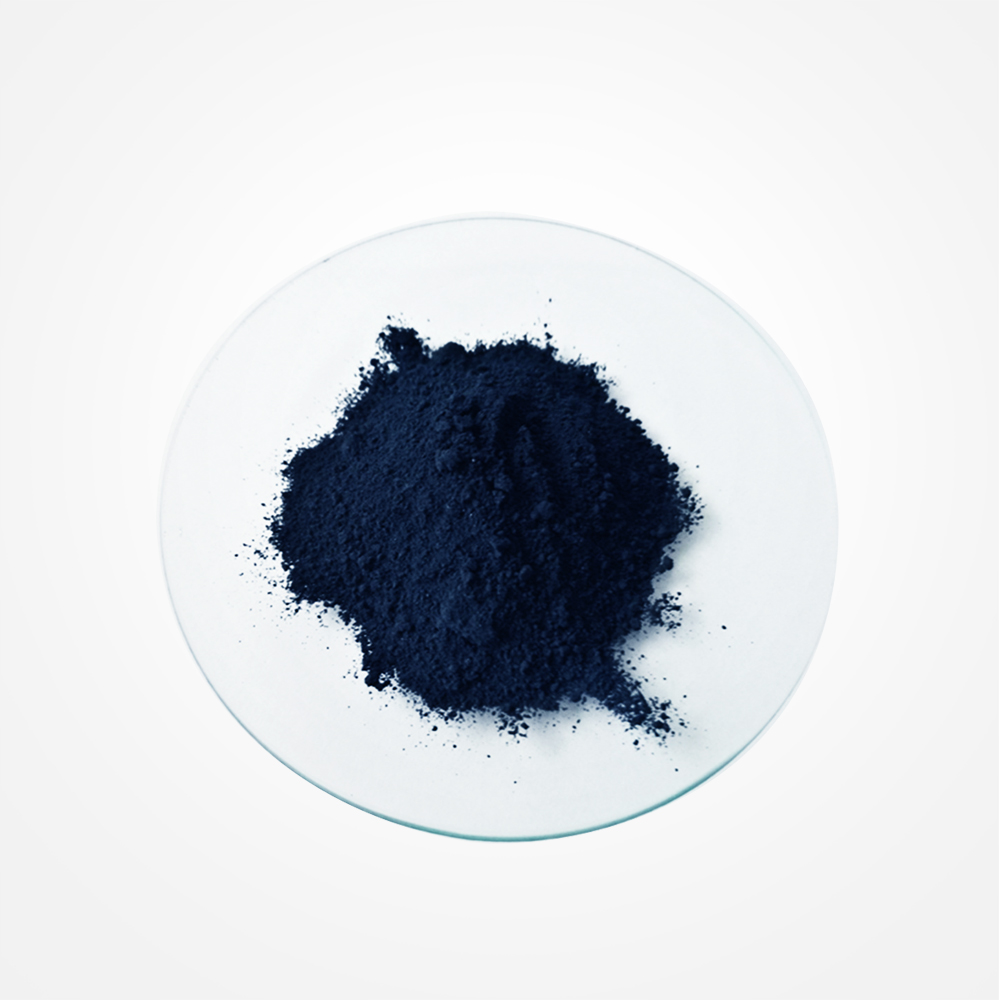

Product Overview

Chromium flakes are high-purity chromium metal flakes produced through an electrolytic process. With a purity of ≥99.95%, these flakes undergo selective anodic dissolution and cathodic deposition to ensure excellent chemical and physical properties. The silver-white chromium flakes have good ductility and corrosion resistance, making them suitable for various industrial applications.

Product Features

- High Purity:Purity of ≥99.95% guarantees outstanding physical and chemical properties

- Excellent Corrosion Resistance:Chromium flakes have strong corrosion resistance, ideal for harsh environments

- Superior Mechanical Properties:Enhances the toughness and strength of steel

- Adjustable Particle Size:Particle size can be customized to meet specific requirements, offering different sizes of chromium flakes

Applications

- Chemical Industry:Used in the production of corrosion-resistant alloys and catalysts

- Refractory Materials:Serves as a high-temperature material widely used in metallurgy and refractory industries

- Metal Materials:Used as an additive in steel alloys to improve mechanical properties, toughness, and oxidation resistance

- Steel Industry:Chromium flakes added to steel significantly enhance its corrosion resistance and strength, widely applied in automotive, aerospace, and other industries

| Chromium metal specifications and physical indicators | ||||||||||||

| Grade | Purity | Chemical Composition (Not Exceeding %) | ||||||||||

| Fe | AL | Si | V | Cu | Bi | C | N | 0 | S | P | ||

| Cr-1 | 99.95% | 0.01% | 0.01% | 0.01% | 0.00% | 0.01% | 0.00% | 0.01% | 0.00% | 0.02% | 0.00% | 0.00% |

| Cr-2 | 99.90% | 0.01% | 0.01% | 0.01% | 0.00% | 0.01% | -- | 0.03 | 0.00% | 0.03% | 0.00% | 0.00% |

new material

new material