Product Overview

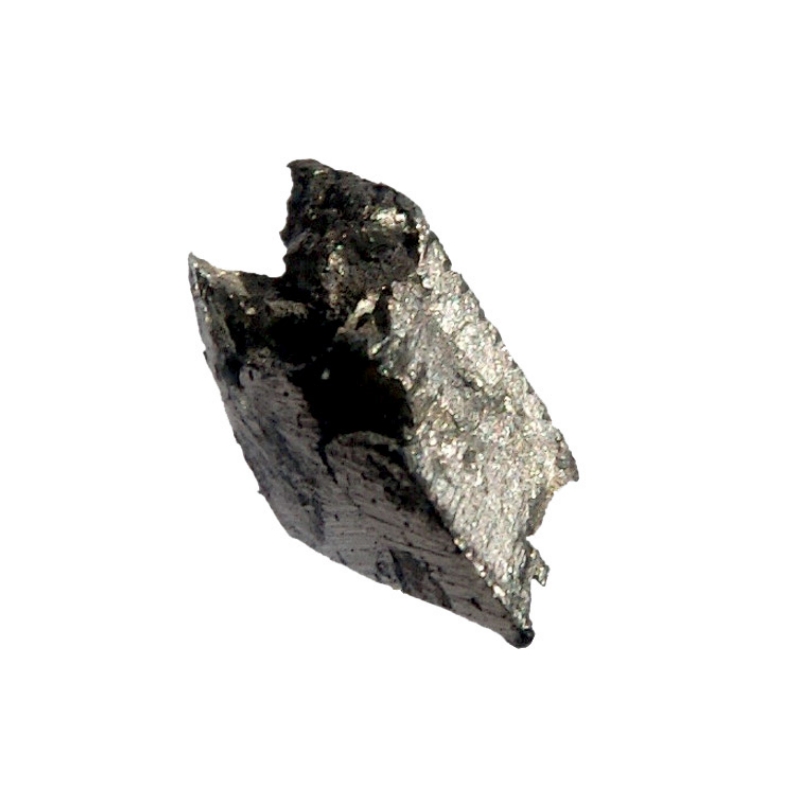

Cerium lump is a solid, silvery-gray material made from cerium, a rare earth element. It has a high melting point and density. While cerium is stable in air, its powder form is highly reactive and can self-ignite. It is soluble in acids. Named after the asteroid Ceres, cerium is one of the more abundant rare earth elements in the Earth's crust and is widely used across various industrial applications.

Key Features

- Silvery-gray Solid:A dense, stable material with a distinctive color.

- Melting Point of 799°C, Density of 6.9g/cm³:Shows good thermal stability and solid structure.

- Excellent Reducibility and Chemical Reactivity:Ideal for various industrial processes.

- Versatile Industrial Applications:Widely used in metallurgy, petrochemical, glass, ceramics, and more.

Applications

- Metallurgical Industry:Used as an alloy additive to enhance the strength, wear resistance, and corrosion resistance of metals.

- Petrochemical Industry:Functions as a catalyst in processes like petroleum cracking, isomerization, and hydrogenation, improving product quality and yield.

- Glass Manufacturing:Used as a decolorizing and clarifying agent to improve glass transparency and quality.

- Ceramics Industry:Enhances mechanical strength, thermal stability, and wear resistance in ceramic products.

- Optical Materials:Used in the production of optical fiber amplifiers to improve signal quality and transmission distance in fiber optic communications.

- Fluorescent Materials:Applied in the production of fluorescent lamps, displays, and X-ray intensifying screens to increase luminous efficiency and stability.

- Magnetic Materials:Used in the production of permanent magnets and soft magnetic materials to improve magnetic properties and reduce production costs.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | 50 | ppm | |||||||

| Na | As | Tb | 50 | ppm | |||||||

| Mg | Se | Dy | 200 | ppm | |||||||

| Al | Zr | Gd | 180 | ppm | |||||||

| Si | 120 | ppm | Nb | Sm | 100 | ppm | |||||

| P | Mo | Yb | 100 | ppm | |||||||

| Cl | Pd | Eu | 100 | ppm | |||||||

| K | Ag | In | |||||||||

| Ca | 2300 | ppm | Sn | ||||||||

| Ti | Sb | ||||||||||

| V | Ba | ||||||||||

| Cr | ppm | Hf | |||||||||

| Mn | <500 | ppm | Ta | C | 100 | ppm | |||||

| Fe | <500 | ppm | W | 350 | ppm | S | |||||

| Co | Pt | O | |||||||||

| Ni | <500 | ppm | Au | N | |||||||

| Cu | Hg | H |

new material

new material